locally oxidized sns 2 Process for the preparation of flakes and their products and uses

A technology of local oxidation and thin slices, which is applied in the direction of chemical instruments and methods, chemical/physical processes, tin compounds, etc., can solve the problems of few active sites, weak intrinsic activity, low yield of thin slices and cannot produce thin slices, and achieve the source Effects of rich, broad social and economic significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

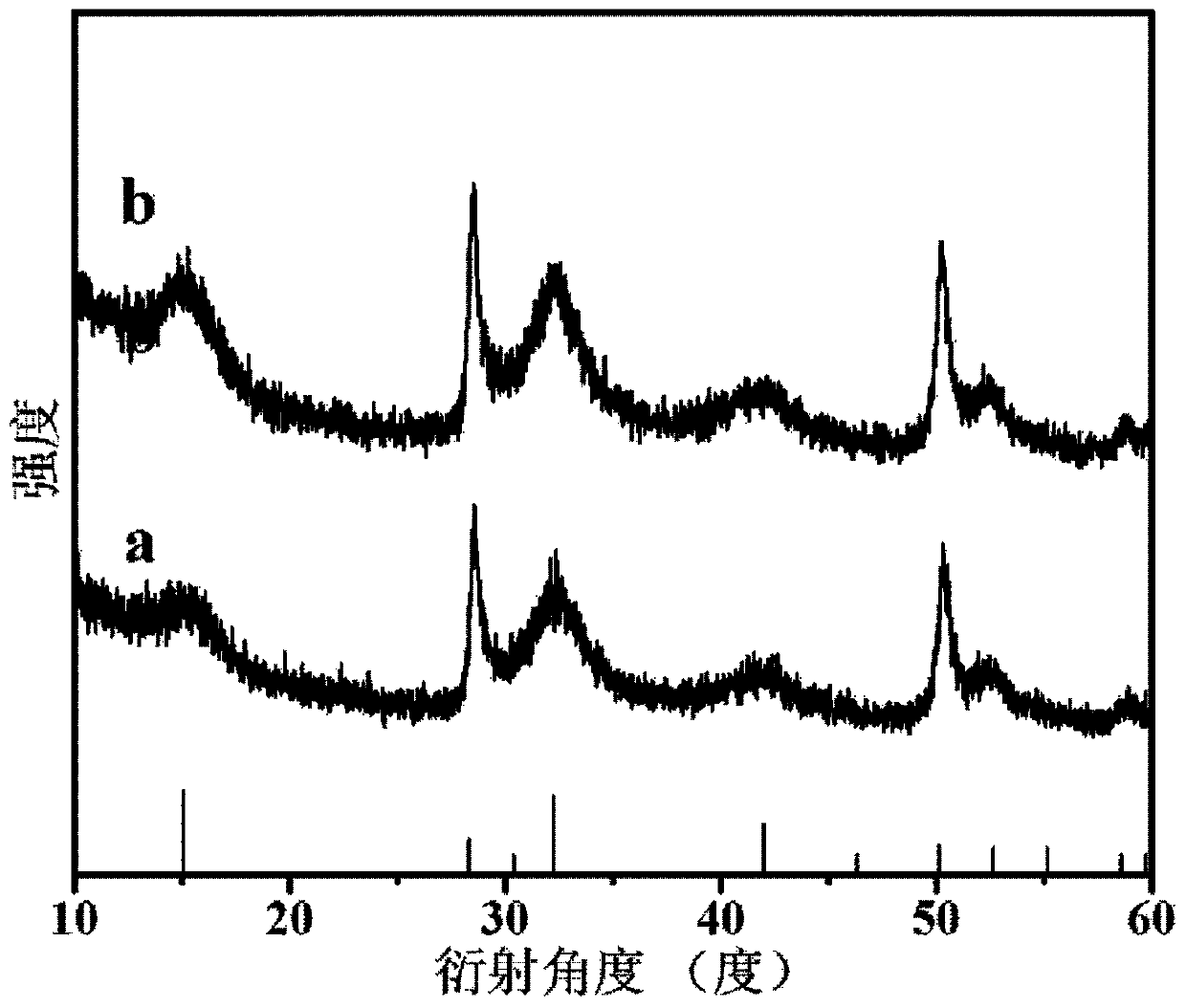

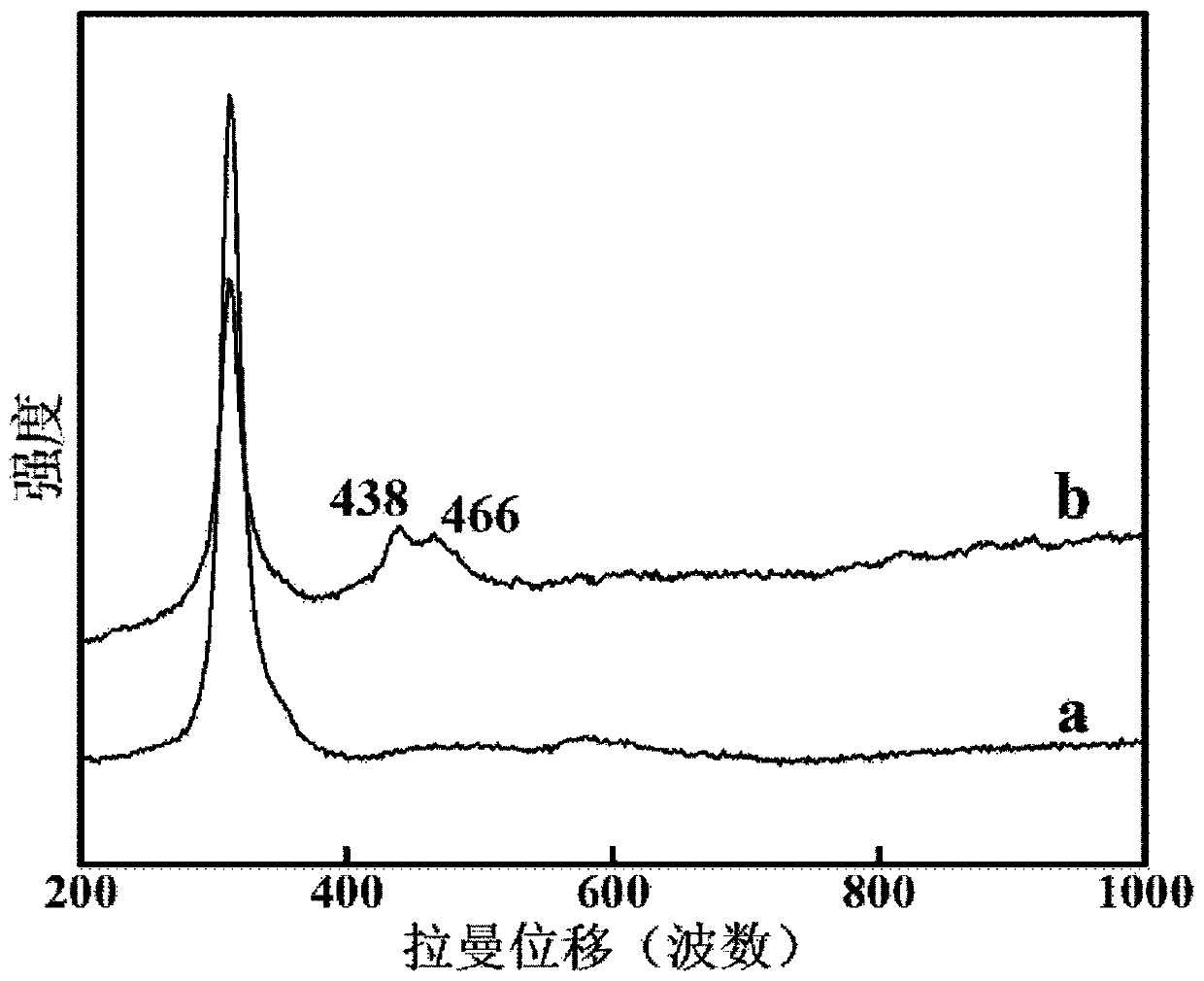

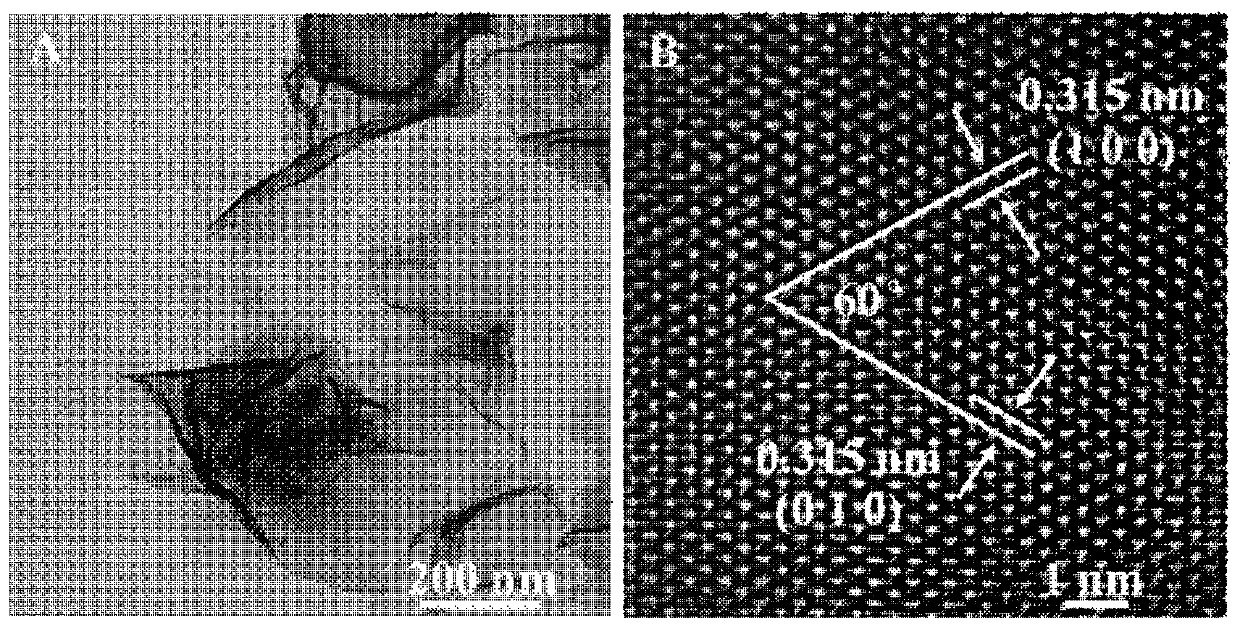

Embodiment 1

[0034] In a polytetrafluoroethylene autoclave, 300mg sodium dodecylbenzenesulfonate (Sinopharm Chemical Reagent Co., Ltd.), 88mg tin tetrachloride (Sinopharm Chemical Reagent Co., Ltd., purity ≥ 99%) and 240mg L- Cysteine (Sinopharm Chemical Reagent Co., Ltd., purity ≥ 99%) was successively dissolved in 15 mL of deionized water and 15 mL of ethylene glycol mixed solvent, and placed on an electric heating mantle stirrer (Shanghai Meiyingpu Instrument Manufacturing Co., Ltd. 08-2T), after stirring for 30 minutes at a rotating speed of 300r / min, the resulting mixed solvent was poured into a 40mL autoclave and after sealing, it was put into an oven (Shanghai Jinghong Experimental Equipment Co., Ltd. XMTD-8222) and heated to Reaction at 160°C for 10h. After the reaction was completed, it was naturally cooled to room temperature, and centrifuged at a speed of 1000 rpm in a high-speed centrifuge (Anhui Zhongke Zhongjia Scientific Instrument Co., Ltd. HC-3518) to obtain a solid prod...

Embodiment 2

[0037] In a polytetrafluoroethylene autoclave, 300 mg of sodium dodecylbenzene sulfonate (Sinopharm Chemical Reagent Co., Ltd.), 80 mg of tin nitrate (Sinopharm Chemical Reagent Co., Ltd., purity ≥ 99%) and 260 mg of L-cysteine Amino acid (Sinopharm Chemical Reagent Co., Ltd., purity ≥ 99%) was dissolved in 25mL deionized water and 5mL ethylene glycol mixed solvent in turn, and placed on the electric heating mantle stirrer (Shanghai Meiyingpu Instrument Manufacturing Co., Ltd. 08- 2T), after stirring for 30 minutes at a rotating speed of 300r / min, pour the resulting mixed solvent into a 40mL autoclave and after sealing it, put it into an oven (XMTD-8222 from Shanghai Jinghong Experimental Equipment Co., Ltd.) and heat it to 165°C Reaction 10h. After the reaction was completed, it was naturally cooled to room temperature, and centrifuged at a speed of 1000 rpm in a high-speed centrifuge (Anhui Zhongke Zhongjia Scientific Instrument Co., Ltd. HC-3518) to obtain a solid product, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com