Preparation of ethylenediamine-coated cadmium telluride nanobelt photocatalyst and separation method of uranium in radioactive wastewater

A technology of radioactive wastewater and photocatalyst, which is applied in the direction of physical/chemical process catalyst, radioactive purification, organic compound/hydride/coordination complex catalyst, etc., and can solve the problem of lack of active adsorption sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

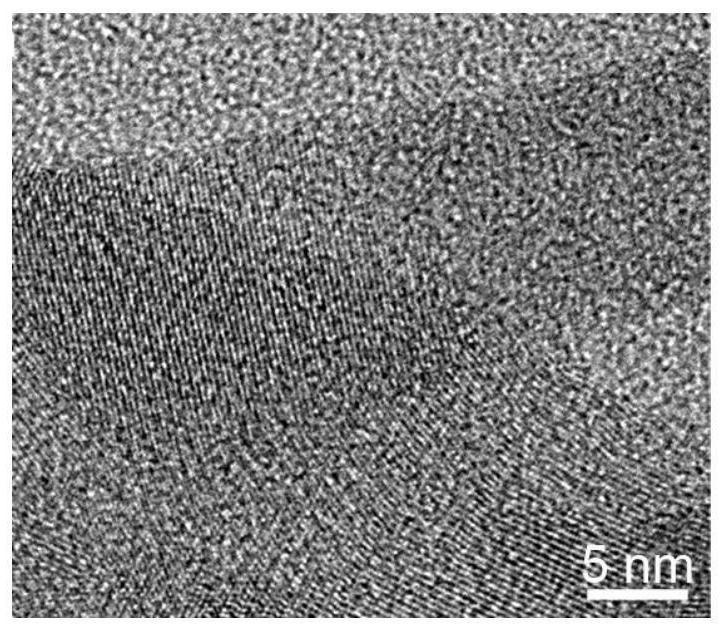

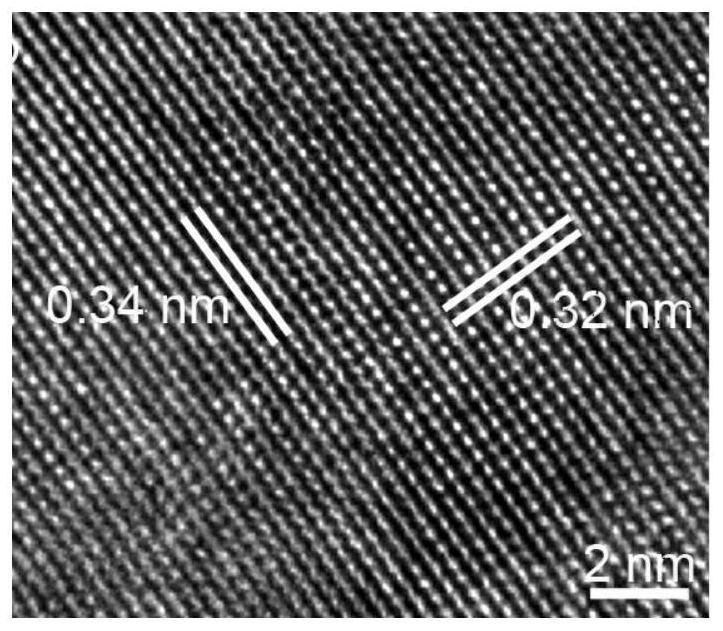

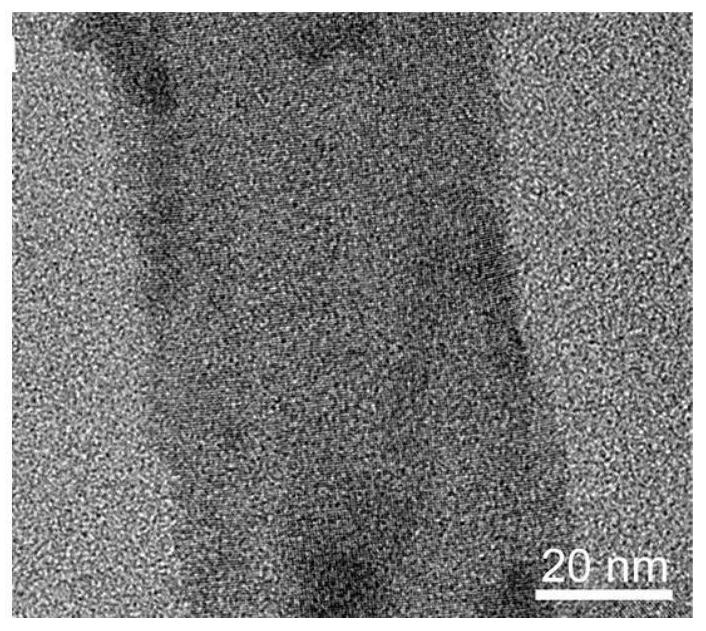

[0044] A preparation method of ethylenediamine-coated sulfur cadmium telluride nanobelt photocatalyst, comprising the following steps:

[0045] Step 1. Preparation of cadmium sulfide nanobelts: Add 1 mmol of cadmium chloride to 30 mL of ethylenediamine, stir evenly, add a mixture of 1 mmol of sulfur powder and tellurium powder, continue stirring evenly, add 3 mL of hydrazine hydrate, and stir for 30 min to obtain a mixed solution; The mol ratio of described sulfur powder and tellurium powder is 0.95:0.05;

[0046] Step 2. Transfer the mixed solution to a 45mL stainless steel reaction kettle and react at 120°C for 8 hours. After the reaction, the product is collected by centrifugation, washed three times with pure water and ethanol respectively, and the final precipitate is vacuum-dried at 60°C to obtain sulfur Cadmium Telluride Nanoribbon Photocatalyst, CdS 0.95 Te 0.05 -EDA; wherein EDA represents ethylenediamine;

Embodiment 2

[0048] A preparation method of ethylenediamine-coated sulfur cadmium telluride nanobelt photocatalyst, comprising the following steps:

[0049] Step 1. Preparation of cadmium sulfide nanobelts: Add 1 mmol of cadmium chloride to 30 mL of ethylenediamine, stir evenly, add a mixture of 1 mmol of sulfur powder and tellurium powder, continue stirring evenly, add 3 mL of hydrazine hydrate, and stir for 30 min to obtain a mixed solution; The mol ratio of described sulfur powder and tellurium powder is 0.9:0.1;

[0050]Step 2. Transfer the mixed solution to a 45mL stainless steel reaction kettle and react at 120°C for 8 hours. After the reaction, the product is collected by centrifugation, washed three times with pure water and ethanol respectively, and the final precipitate is vacuum-dried at 60°C to obtain sulfur Cadmium telluride nanoribbon photocatalyst; i.e. CdS 0.90 Te 0.1 -EDA.

Embodiment 3

[0052] A preparation method of ethylenediamine-coated sulfur cadmium telluride nanobelt photocatalyst, comprising the following steps:

[0053] Step 1. Preparation of cadmium sulfide nanobelts: Add 1 mmol of cadmium chloride to 30 mL of ethylenediamine, stir evenly, add a mixture of 1 mmol of sulfur powder and tellurium powder, continue stirring evenly, add 3 mL of hydrazine hydrate, and stir for 30 min to obtain a mixed solution; The mol ratio of described sulfur powder and tellurium powder is 0.8:0.2;

[0054] Step 2. Transfer the mixed solution to a 45mL stainless steel reaction kettle and react at 120°C for 8 hours. After the reaction, the product is collected by centrifugation, washed three times with pure water and ethanol respectively, and the final precipitate is vacuum-dried at 60°C to obtain sulfur Cadmium Telluride Nanoribbon Photocatalyst, CdS 0.80 Te 0.2 -EDA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com