An adjustable stress relief mechanism for steel cold rolling

A stress-relief, adjustable technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problem of incomplete stress relief, increase multi-directionality, increase stress release limit, and increase elongation rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

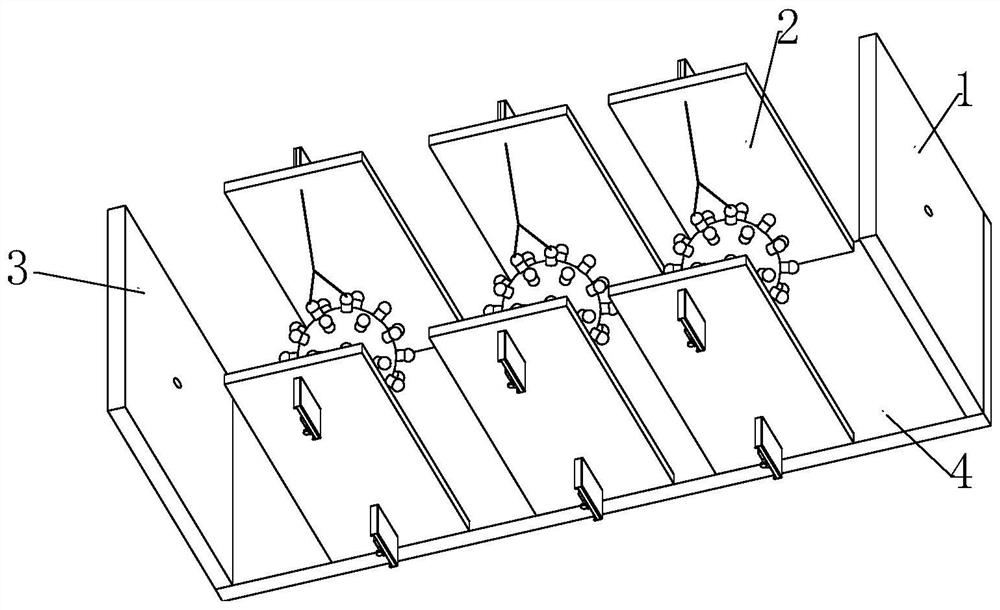

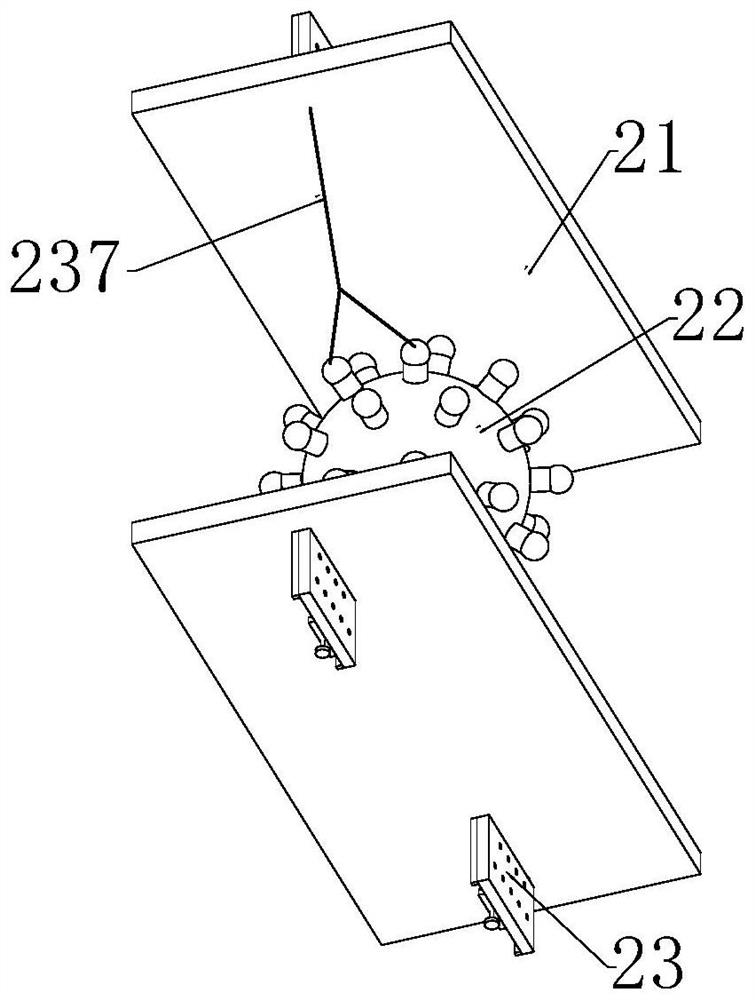

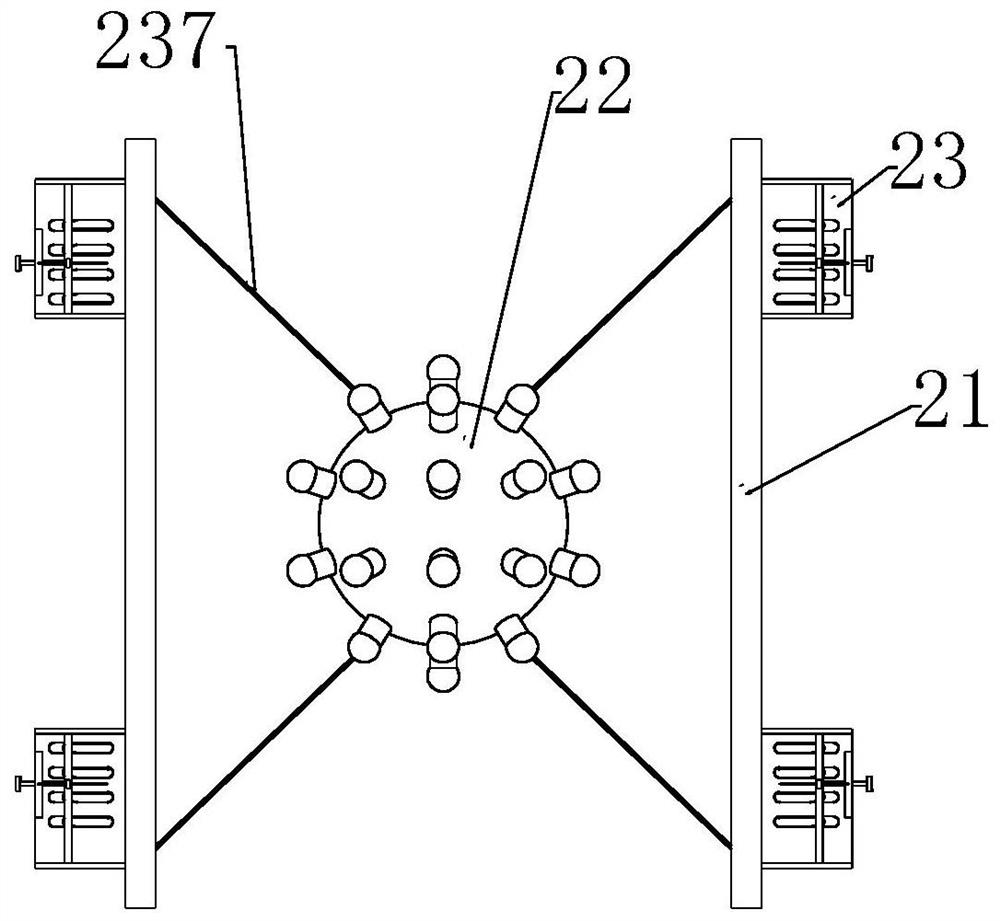

[0036] Specific implementation method: When in use, the steel bar is inserted through the guide hole of the first support plate 1, and bypasses at least two bending components 2 and is moved out through the guide hole on the second support plate 3, wherein the inside of the bending component 2 The vertical plate 21 is used to support the bending piece 22 and the control piece 23. The steel bars can bypass different positions on the bending piece 22 to achieve bending in different directions. The design of the four control pieces 23 can adjust the up and down front and rear positions of the bending piece 22 , so that the horizontal and vertical positions of two adjacent bending pieces 22 are different, further increasing the multi-directionality of the bending of the steel bar, improving the stress release limit inside the steel bar, and increasing the elongation of the steel bar.

[0037] Rotate the adjusting screw rod 233, due to the threaded connection between the adjusting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com