Melting impregnation equipment for carbon fiber composite materials for automobiles

A composite material and melt impregnation technology, which is applied in the field of melt impregnation equipment for carbon fiber composite materials for automobiles, can solve the problems of insufficient adhesion, poor fluidity, and difficulty in impregnating carbon fibers, so as to improve product quality, improve thoroughness, and improve more directional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

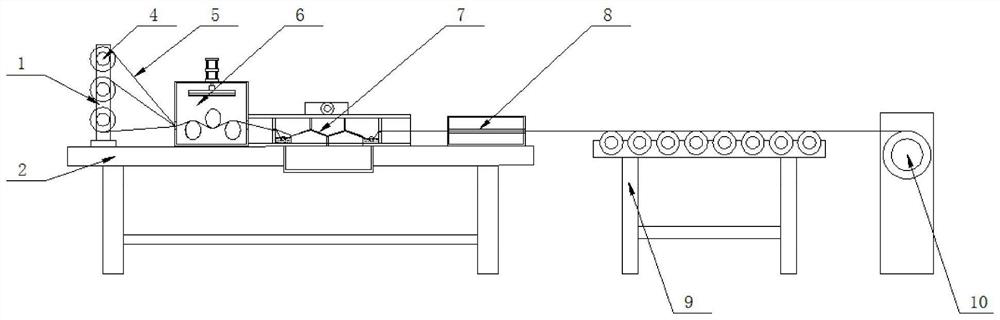

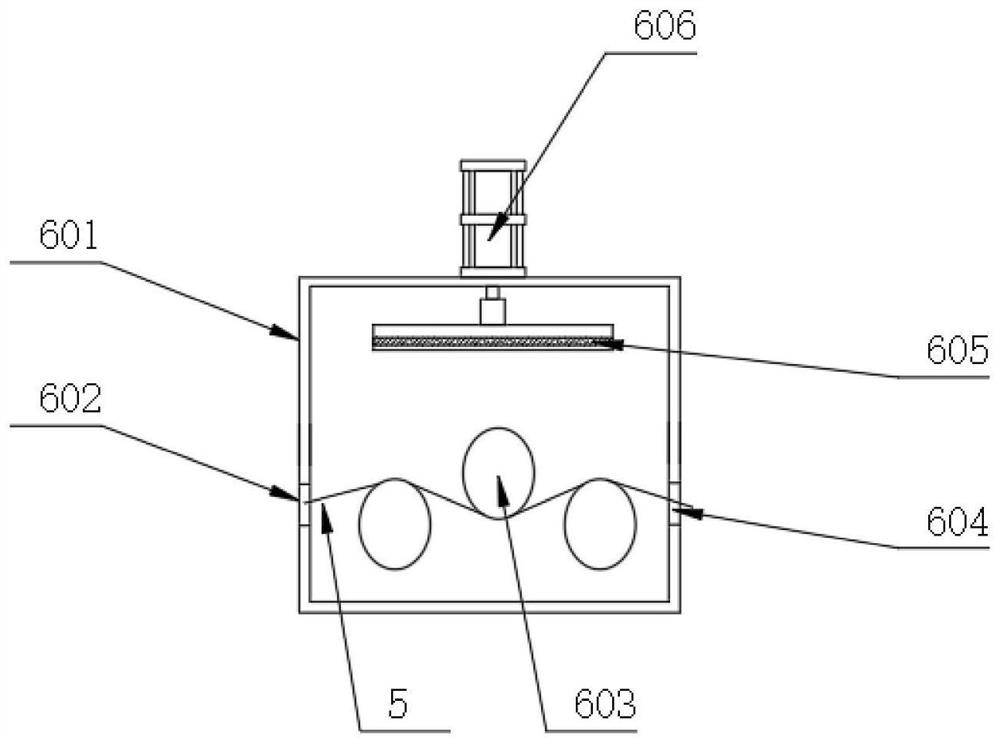

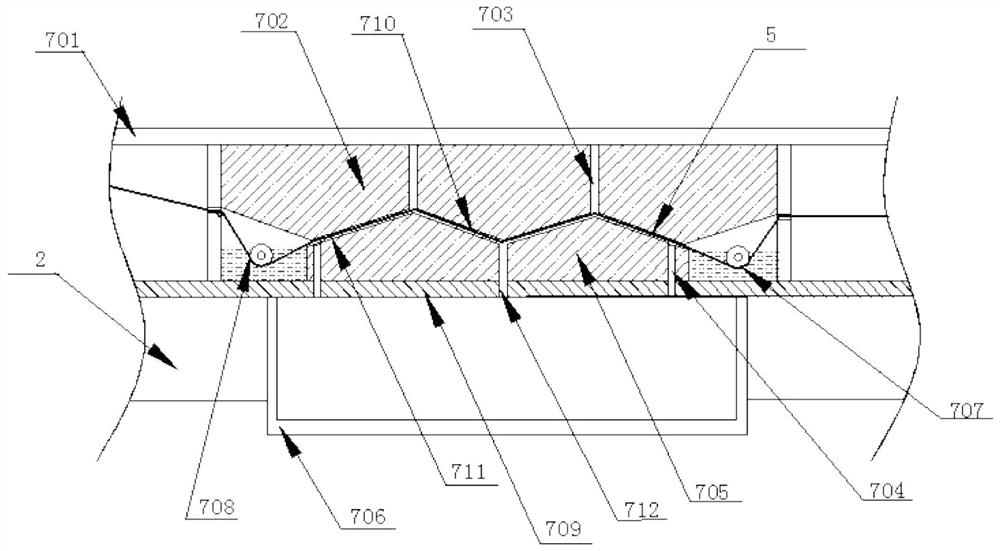

[0025] see Figure 1~4 , in an embodiment of the present invention, a carbon fiber composite material melt impregnation equipment for automobiles, which includes an upper impregnation mold base 702 and a lower impregnation mold base 705, and the upper and lower impregnation mold bases 702 and the lower impregnation mold base 705 are arranged to be buckled up and down , and the upper impregnation mold base and the lower impregnation mold base are sequentially provided with a pre-impregnation chamber 708, a longitudinal impregnation chamber 7 and a final impregnation chamber 707, wherein the carbon fiber composite material 5 to be impregnated passes through the Prepreg chamber 708, vertical impregnation chamber 7 and final impregnation chamber 707; the viscosity of the melt in the prepreg chamber 708 is greater than the viscosity of the melt in the final impregnation chamber 707; and the longitudinal impregnation chamber 7 The melt inside can flow along the direction of extensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com