Pipe distributing and feeding method and device

A pipe and material separation technology, applied in transportation and packaging, laser welding equipment, conveyors, etc., can solve the problems of low feeding and material separation efficiency, complex structure, easy deformation of beams, etc., to improve efficiency, reduce beam load, Reduce the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

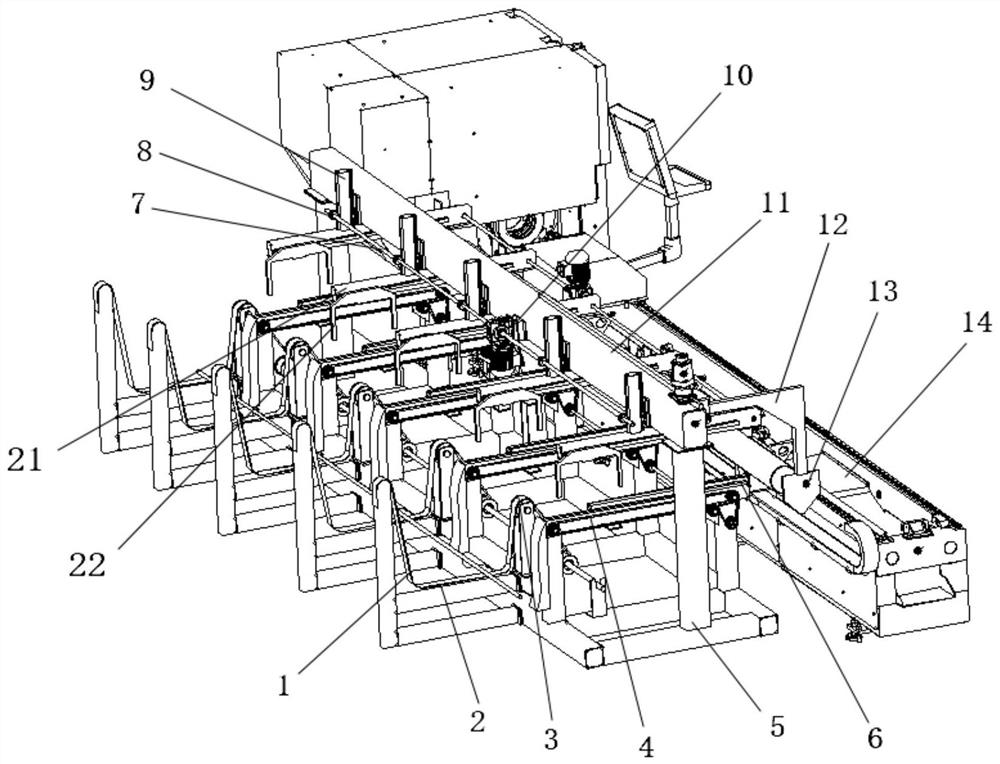

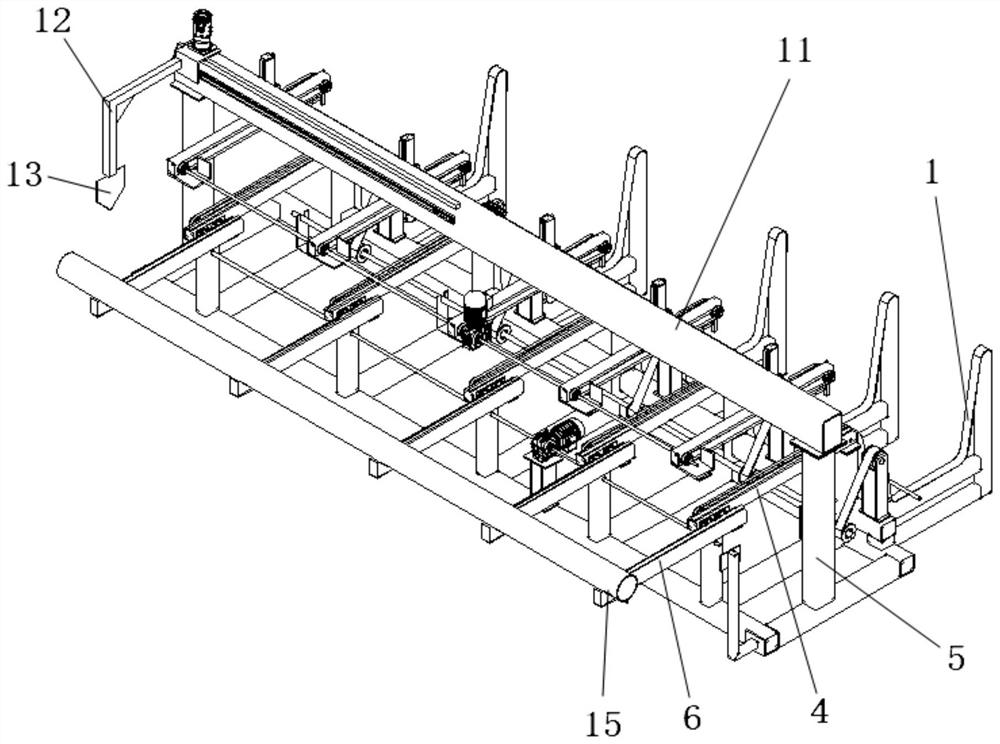

[0035] like figure 1 and figure 2As shown, the present invention provides a pipe material distribution and feeding device, which mainly includes a bundle material feeding mechanism, a support, a support platform, a material distribution mechanism, a pipe limit mechanism, and a pipe cutting machine main body 14, a support platform and a distribution platform. The material mechanism is installed on the support, and the support platform is located at the side of the discharge port of the bundle feeding mechanism. A push mechanism is installed on the support platform, which can send the pipes on the support platform to the main body 14 of the pipe cutting machine. The positioning mechanism also measures the length of the pipe while limiting the position of the pipe on the main body 14 of the pipe cutting machine. Wherein, the bearing is divided into base 5 and crossbeam 11 two parts, and crossbeam 11 is installed on the top of base 5 and is supported by base 5 to crossbeam 11; ...

specific Embodiment approach 2

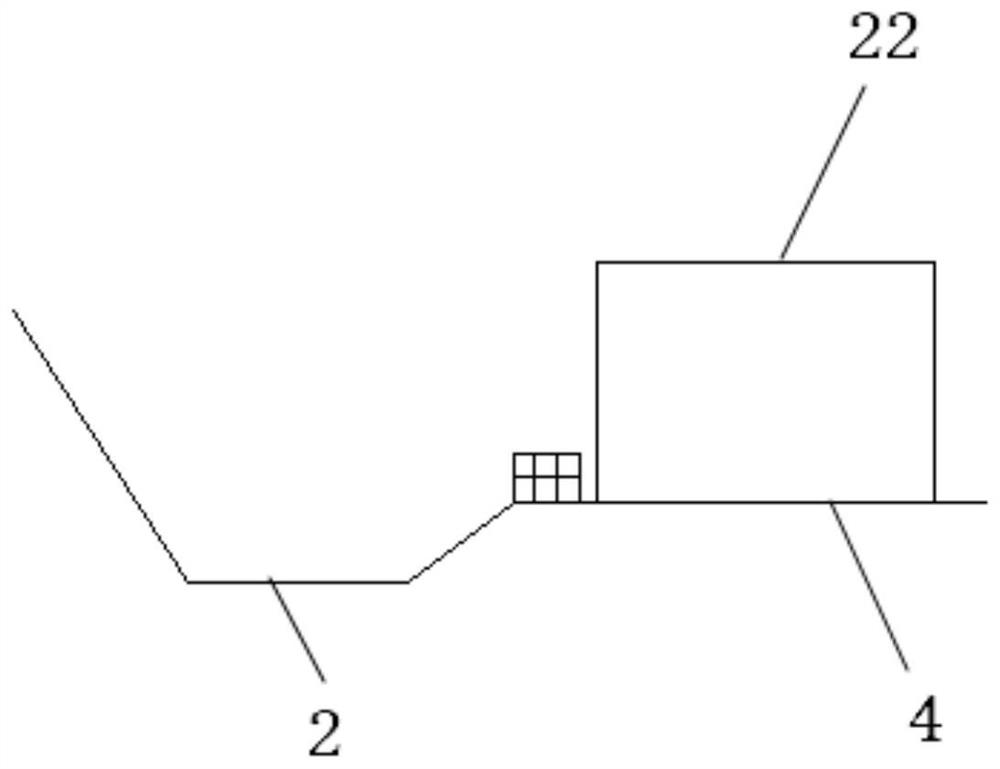

[0038] On the basis of the specific embodiment 1, this specific embodiment provides a pipe material distribution and feeding method, the method is: the bundled pipes are placed in the placement groove 2, and the lifting belt 1 is driven by the power unit to drive the bundled pipes Moving from the placement slot 2 to the upper feeding port, the material distribution fork 22 moves to the feeding port of the bale feeding mechanism through lifting and translation, and will be pushed by the front end of the material distribution fork 22. One or two pipes pass into the support beam 4 and are supported by the support beam 4. Wherein, the distribution shift fork 22 is lowered to its bottom lower than the bottom pipe to be able to push all the pipes to move, and the distribution shift fork 22 Move backwards, use the front end of the separation fork 22 to push the pipe to push the part of the pipe at the rear back into the placement groove 2, then the distribution fork 22 rises to slight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com