Robot-assisted continuous resistance welding equipment and welding method for thermoplastic materials

A robot-assisted, thermoplastic material technology, applied in the field of composite material manufacturing, can solve problems such as uneven temperature distribution, high applied pressure, and uneven welding pressure, so as to improve welding efficiency and welding quality, high welding efficiency and good welding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

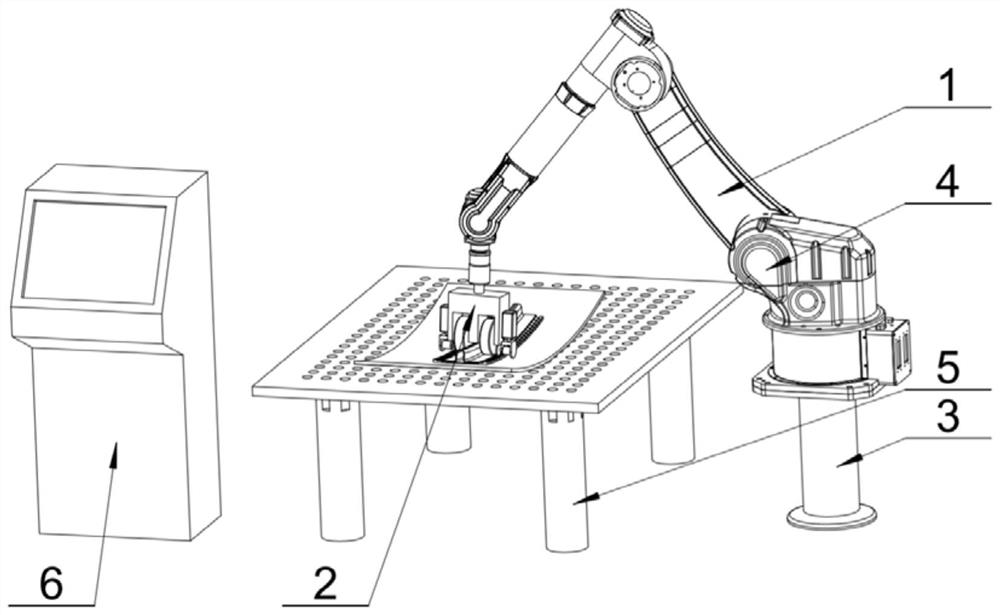

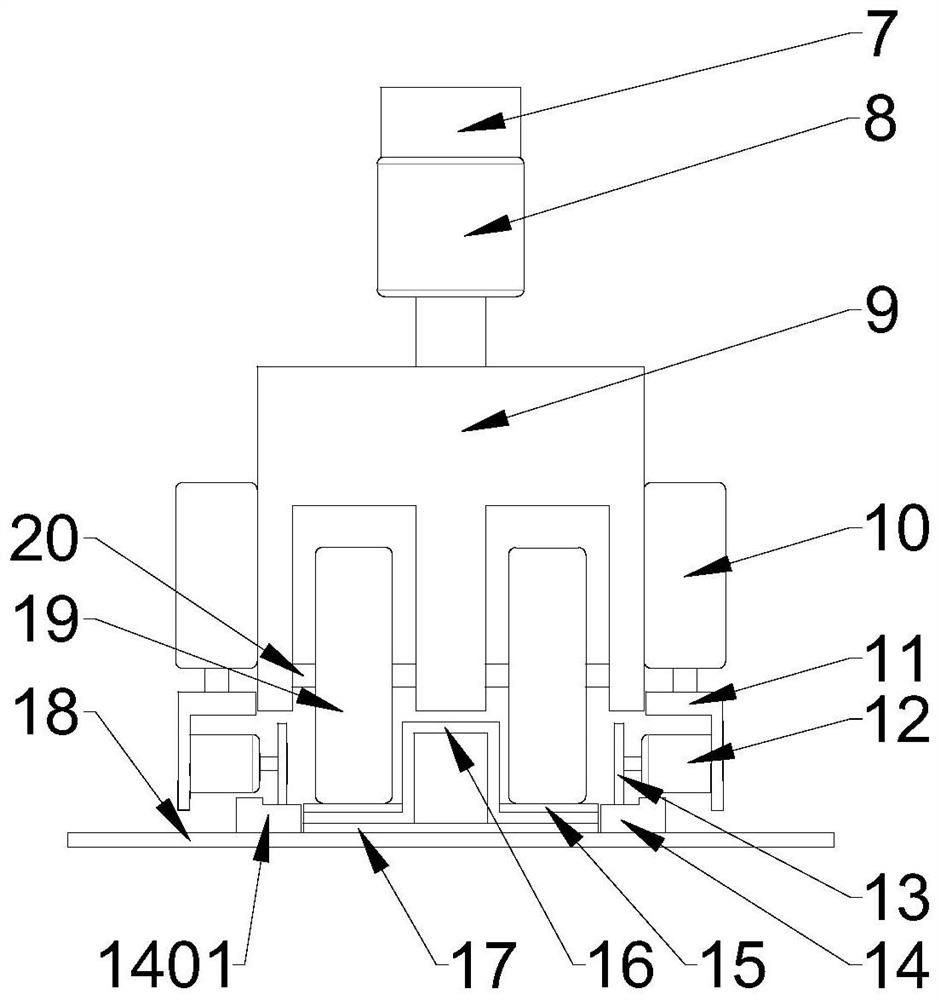

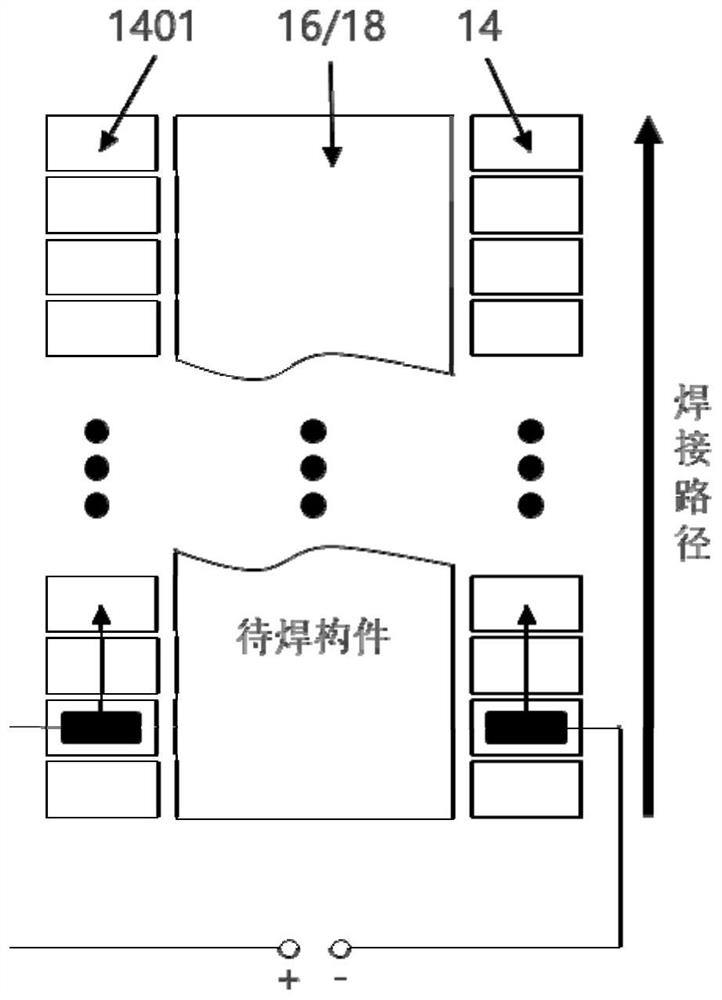

[0038] Example 1: Welding of hat-shaped piece and curved plate (double roll)

[0039] Such as figure 1 with figure 2 As shown, first, the second member 18 to be welded is fixed on the welding work platform 5, and the input electrode 14 and the output electrode 1401 are respectively bonded to the surface of the second member 18 to be welded using water-soluble glue. Such as image 3 As shown, a gap of 1 mm is provided between adjacent electrodes to realize segmented continuous energization of the heating material 17. After the welding work starts, parameters such as input power, movement speed, welding pressure, energization time and energization frequency are set through the industrial control cabinet 6. The robot arm 4 walks along the preset welding path, and the hydraulic cylinder 8 applies the preset welding pressure. At the same time, the actual welding pressure is fed back through the pressure sensor 7, and the industrial control cabinet 6 is further adjusted to make the ap...

Example Embodiment

[0040] Example 2: Welding of L-shaped parts and curved plates (single roll)

[0041] Such as Figure 4 As shown, the robot-assisted continuous resistance welding equipment of this embodiment includes two parts: a motion control module 1 and a continuous pressure welding module 2. The difference from the first embodiment is that the continuous pressure welding module uses a single pressure roller 19 to continuously apply stable pressure to the first member 16 to be welded.

[0042] In summary, the discontinuous and continuous distribution of the multiple sets of electrodes of the continuous pressure welding module of the present embodiment along the weld seam can realize segmented continuous heating welding of the components to be welded. At the same time, it can realize the integrated control of welding pressure, welding speed, welding power, welding temperature and other process parameters, and can weld full-size weld structure parts, which solves the problem of uneven heating te...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap