Anti-solidification ink storage box for printer

An anti-solidification technology for printers, applied in the field of printers, can solve the problems of difficult preservation and easy solidification of ink, and achieve the effects of improving printing effect, reducing energy consumption, and reducing the probability of solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

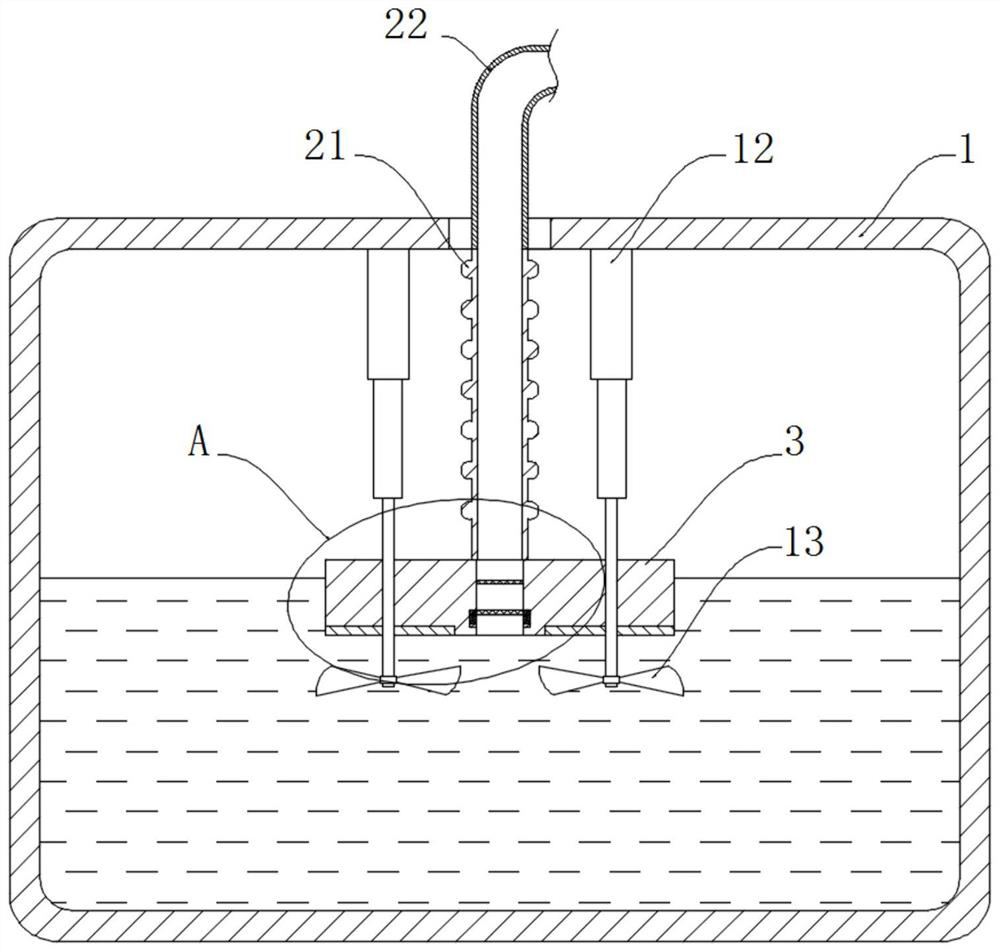

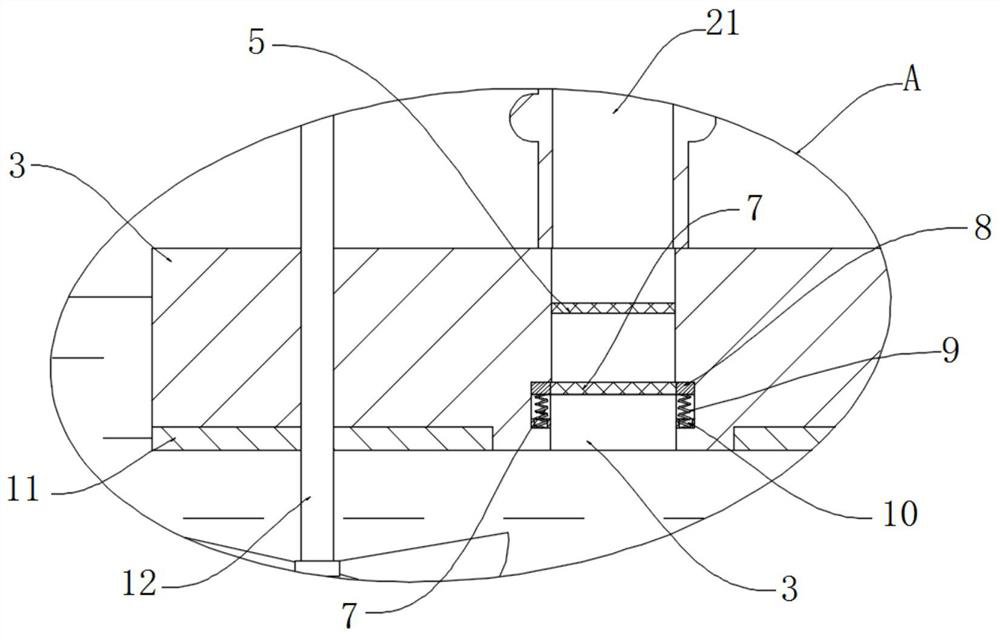

[0019] refer to Figure 1-2 , an anti-freezing ink storage box for a printer, comprising a box body 1 filled with ink, the top of the box body 1 is provided with a discharge port and the discharge port is sealed and connected with a discharge pipe 22, and the discharge pipe 22 is connected to the outside The negative pressure machine is connected, and the end of the discharge pipe 22 located in the box body 1 is fixedly connected with the floating block 3 through the bellows 21. The density of the floating block 3 is less than the density of the ink, and the feeding channel 4 is run through the floating block 3, and Feed passage 4 is communicated with discharge pipe 3, is respectively provided with first filter net 5 and the second filter net 6 in the feed passage 4, the first filter net 5 is positioned at the top of the second filter net 6, the first filter net 5 Sealed and fixedly connected to the inner wall of the liquid inlet channel 4, a chute 7 is provided at the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com