Cover tape slitting tool

A cover tape and tooling technology, applied in the directions of transportation and packaging, winding strips, sending objects, etc., can solve the problems of tape cover curling, troublesome blade replacement, manual monitoring of production, etc., and achieve convenient maintenance and ensure separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

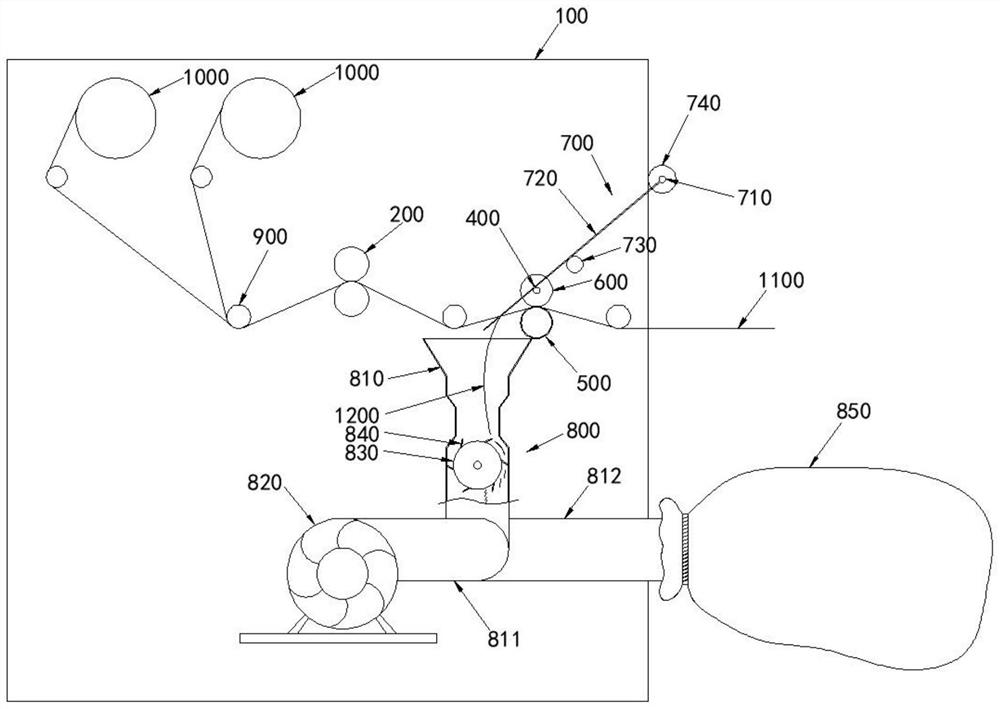

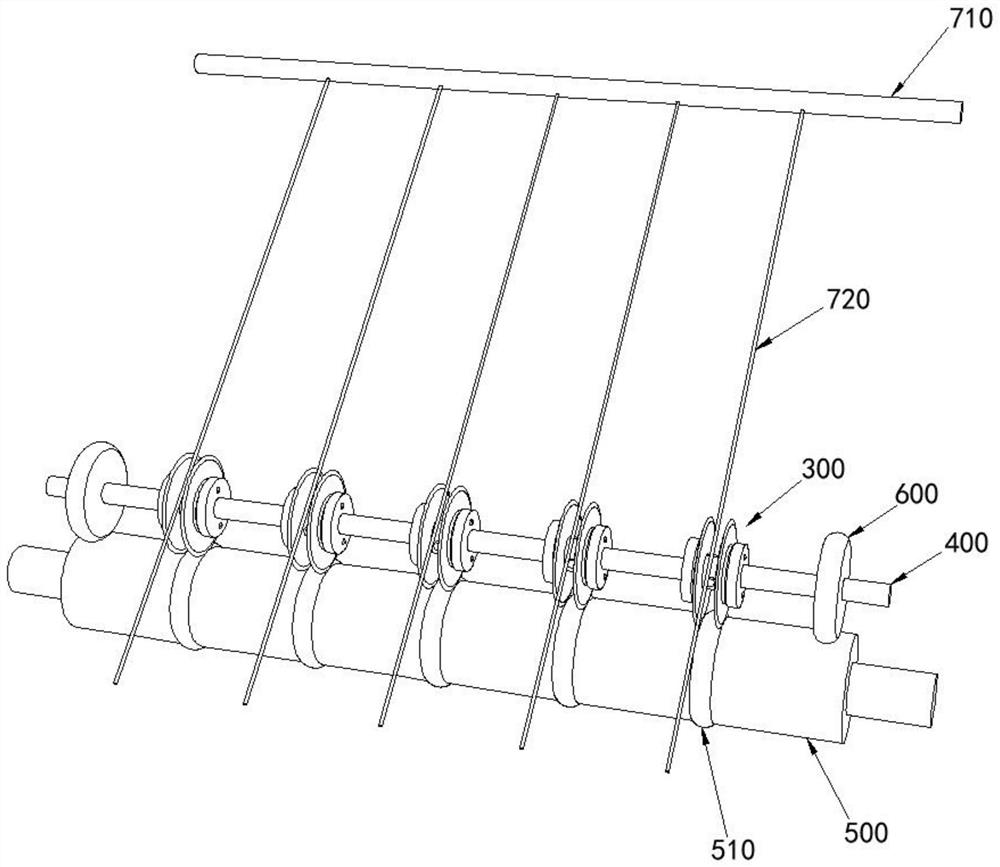

[0030] Such as Figure 1 to Figure 6 As shown, the cover tape slitting tooling of this embodiment includes a frame 100, a driving roller 200, a cutter 300, a cutter shaft 400, a bearing roller 500, a pressing wheel 600, a pressing mechanism 700, a material receiving mechanism 800, and a guide roller 900 And winding roller 1000;

[0031] The driving roller 200, the knife shaft 400, the bearing roller 500, the guiding roller 900 and the winding roller 1000 are all installed on the frame 100. The knife shaft 400 is opposite to the bearing roller 500. The driving roller 200 pulls the cover tape 1100 from the knife shaft 400 and the bearing roller. The rollers 500 pass through and are guided by the guide roller 900 and then are wound on the winding roller 1000 to form a cover tape roll;

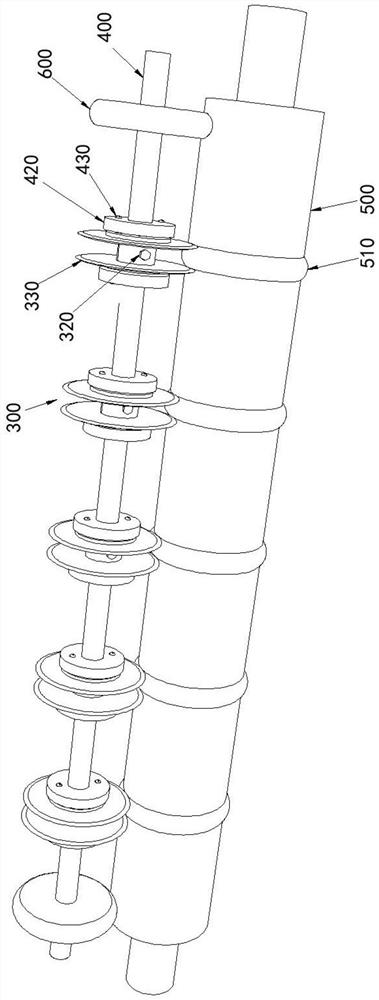

[0032] Such as Image 6 As shown, the tool 300 includes two identical half-blade modules 310 and fastening bolts 320. The half-blade modules 310 include a half I-shaped cylinder 311, a half collar 312 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com