Heavy-duty construction loading and unloading trolleys

A technology for structures and loading and unloading platforms, which is applied to buildings, lifting devices, building structures, etc., can solve problems such as insufficient force, insufficient control precision, and difficulty in carrying heavy structures, so as to reduce occupancy, complexity, and Observe the effect of the steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

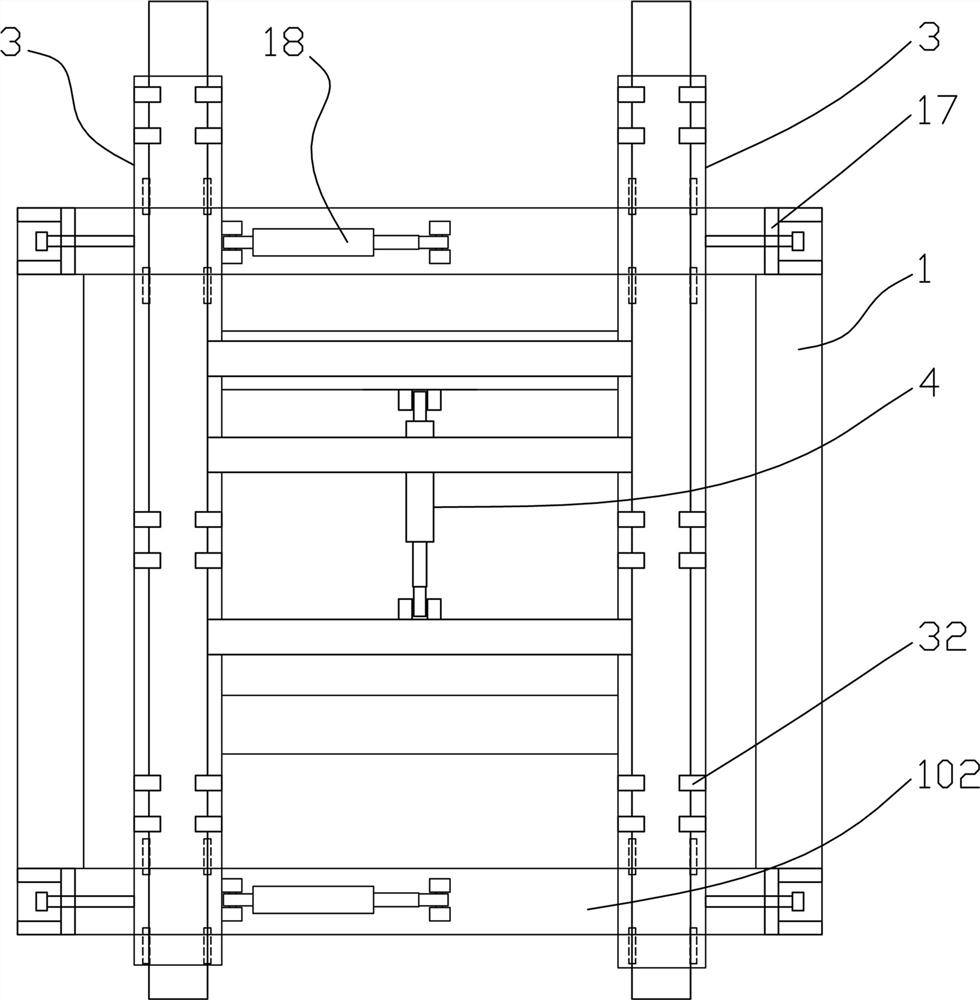

[0077] The steps of setting the barb device 14 on the heavy structure 15, such as Figure 11 , 12 As shown in the figure, the position of the barb device 14 is set, and a separate template is set. The template adopts the structure of a seam template, and a plurality of holes are provided on the template, and a plurality of connecting bolts 25 pass through the holes and are respectively connected with the embedded gasket. The plate nuts 23 are fixedly connected. In this example, each template is provided with at least 4 pre-embedded backing plate nuts 23. This structure ensures that the distance between each pre-embedded backing plate nut 23 is a fixed value. The distance between each bearing pin 13 or bearing seat 12 on the frame 8 is also a fixed value corresponding to the distance between the connecting bolts 25 one-to-one. In order to connect the successor with the loading and unloading frame 8 reliably. The formwork is positioned close to the center of mass of the heavy ...

Embodiment 2

[0079] The loading and unloading frame 8 is provided with a bearing pin 13, a frame mold is used, and a double lug plate corresponding to the position of the bearing pin 13 is set on the mold, such as four double lugs, and the bearing seat 12 is passed through the bearing pin 13 and the double lug plate. Connect to fix the relative position of the bearing seat 12, place the mold as a whole on the front end face of the loading and unloading frame 8, the bearing seat 12 is in contact with the loading and unloading frame 8, connect the bearing seat 12 with the loading and unloading frame 8 by spot welding, and remove the bearing pin 13 Then, the bearing seat 12 and the loading and unloading frame 8 are fully welded. During the welding process, the deformation of the bearing seat 12 is controlled by staggered welding seams. By the above method, it is ensured that the bearing pin 13 and the barb device 14 correspond in position, and the force between them is reliable, and the force ...

Embodiment 3

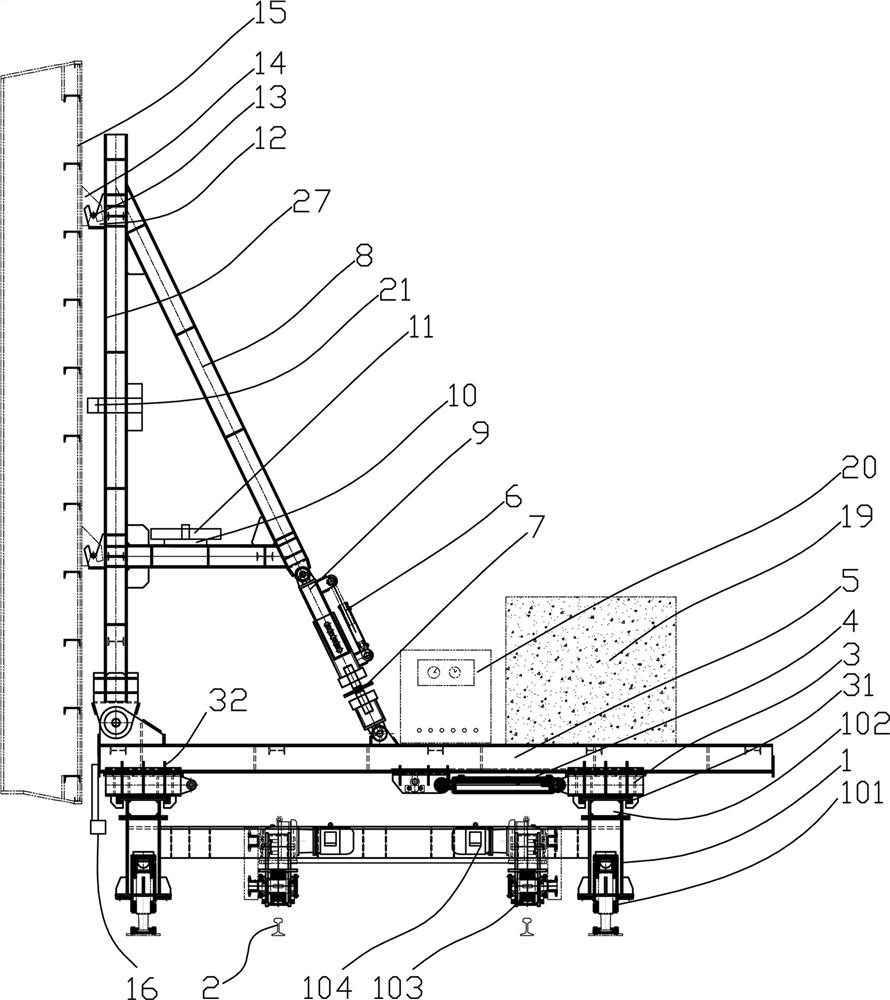

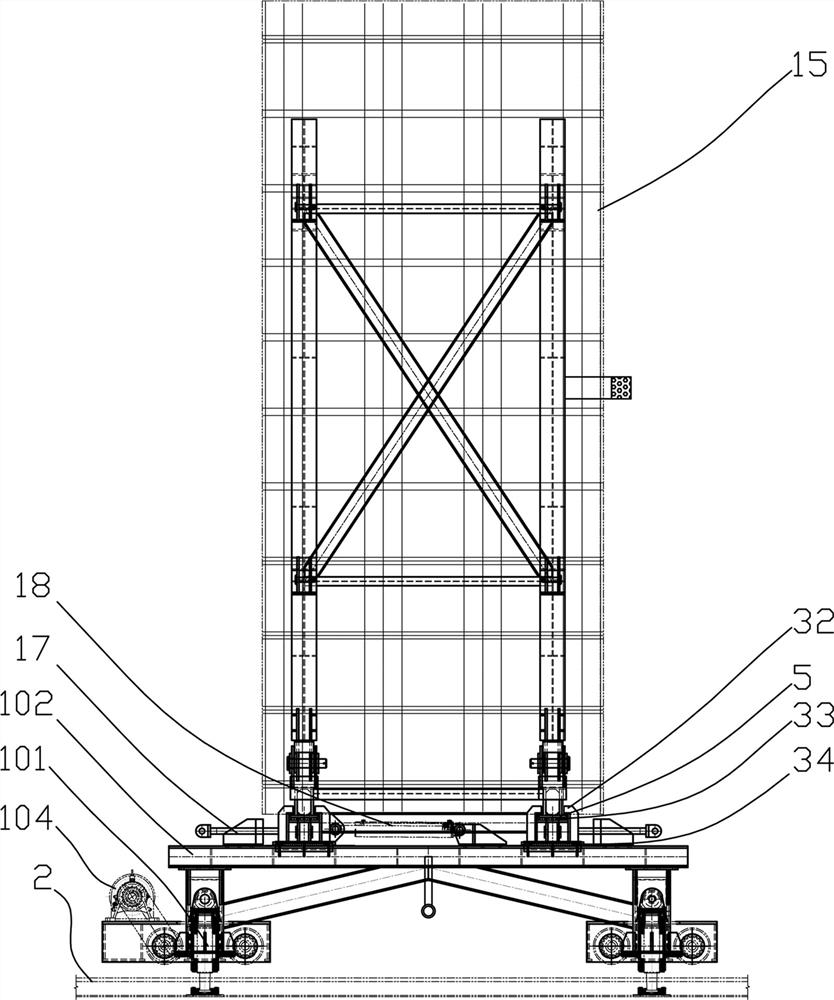

[0081] The auxiliary positioning target 22 is set, and according to the parameter of the spatial distance between the position of the positioning sensor 16 and the installation position, the auxiliary positioning target 22 is offset by a corresponding spatial distance and set near the position to be installed. The traveling frame 1 is located at the hoisting position of the traveling track 2, such as Image 6 shown in. The hoisting device hoists the heavy construction 15 , such as the end sealing door of the sunk pipe, onto the loading and unloading frame 8 , so that the barb device 14 is hooked on the bearing pin 13 . After the installation is fixed, the driving device 104 drives the traveling frame 1 to travel along the traveling track 2 to the installation station. According to the inclination angle of the installation position, the hydraulic oil output from the hydraulic station 20 controls the expansion and contraction of the piston rod of the tilt cylinder 6, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com