A simple manipulator of an industrial robot

A technology of industrial robots and manipulators, which is applied in the field of robots, can solve problems such as complex structure of the gripper, high cost of manual handling, and harm to human health, and achieve the effects of flexible use, flexible use, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

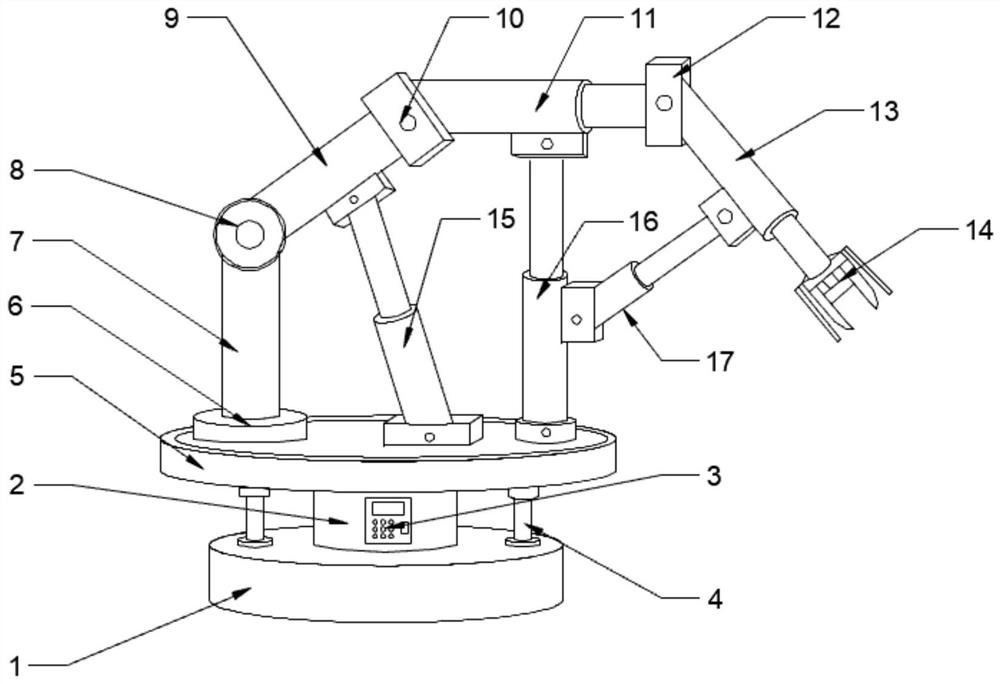

[0021] see Figures 1 to 3 In the embodiment of the present invention, a simple manipulator for an industrial robot includes a fixed base 1; a control box 2 is installed on the top of the fixed base 1; a control panel 3 is arranged on the control box 2; There is a working mechanism 5; the top of the working mechanism 5 is fixedly installed with a fixing table 6; the fixing table 6 is connected to the No. 1 fixing rod 7; The No. 2 fixed rod 9 is connected to the No. 1 electro-hydraulic telescopic rod 11 through the No. 2 installation mechanism 10; One end of the No. 2 electro-hydraulic telescopic rod 13 away from the No. 3 mounting mechanism 12 is movably installed with a mechanical claw 14 .

[0022] Further, the fixed base 1 and the working mechanism 5 are fixedly connected by a fixed rod 4; the setting of the fixed rod 4 increases the stability of the device during operation.

[0023] Further, the control box 2 is communicated with the working mechanism 5; the control box ...

Embodiment 2

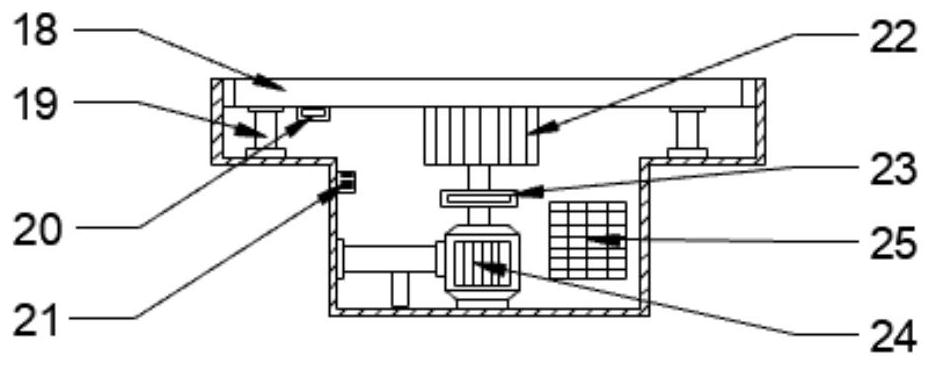

[0028] see figure 2 , a pressure sensor 20 is installed at the bottom end of the rotating disk 18; the pressure sensor 20 is electrically connected to the alarm 21; the alarm 21 is electrically connected to the PLC control circuit board 25; The setting of the PLC control circuit board 25 can prevent the device from being damaged due to excessive pressure when the device is in use.

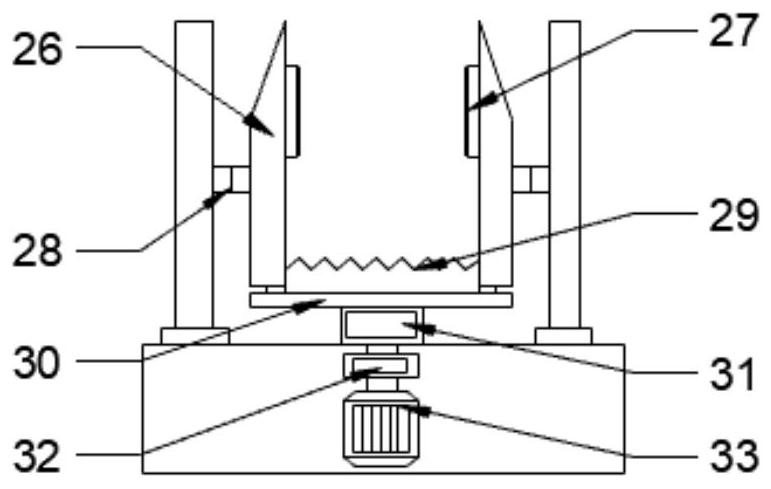

[0029]The working principle of the present invention is as follows: through the setting of the fixed rod 4, the stability of the device during operation is increased; through the No. 1 driving motor 24, the PLC control circuit board 25, the No. 1 reversing mechanism 23, the gear 22, the rotating disk 18, the support The setting of the rod 19 can adjust the angle of 360 degrees according to the angular relationship between the object and the mechanical claw 14, and the use is more flexible; The setting of the electro-hydraulic telescopic rod 17 can precisely adjust the spatial position of the mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com