Ultrasonic high-precision, high-efficiency welding equipment

A welding equipment and high-precision technology, which is applied in the field of high-efficiency welding equipment and ultrasonic high-precision, can solve the problems of affecting welding accuracy, affecting welding speed, and insufficient efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

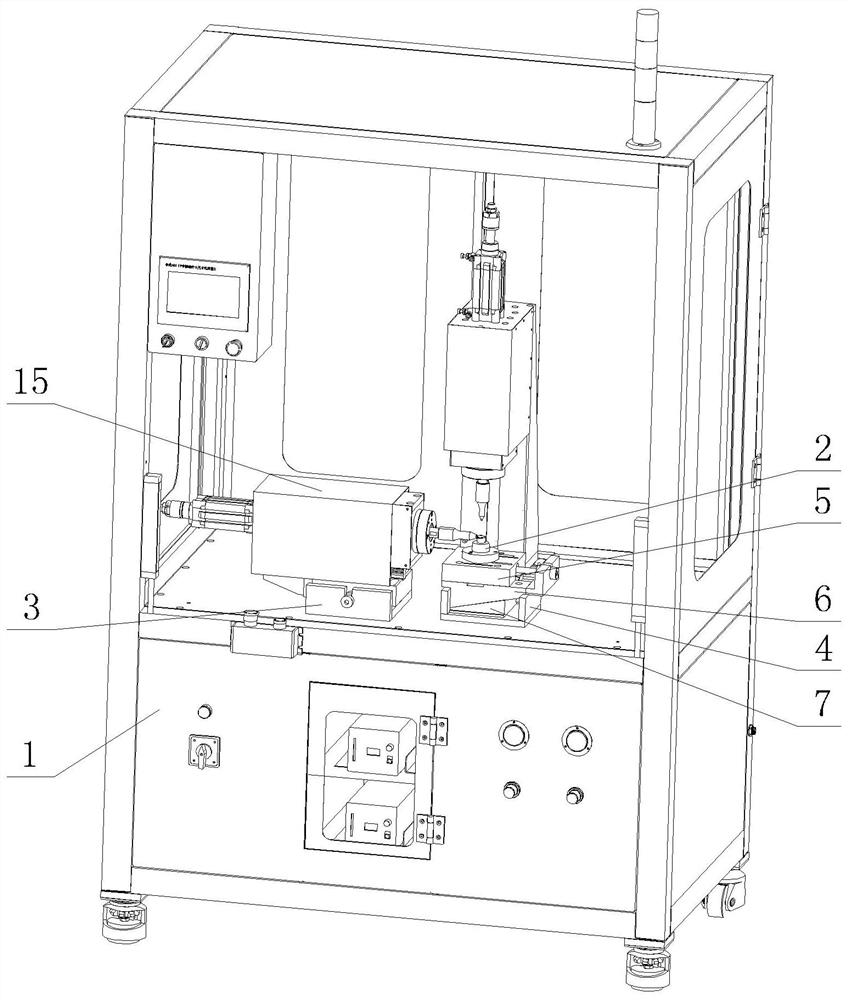

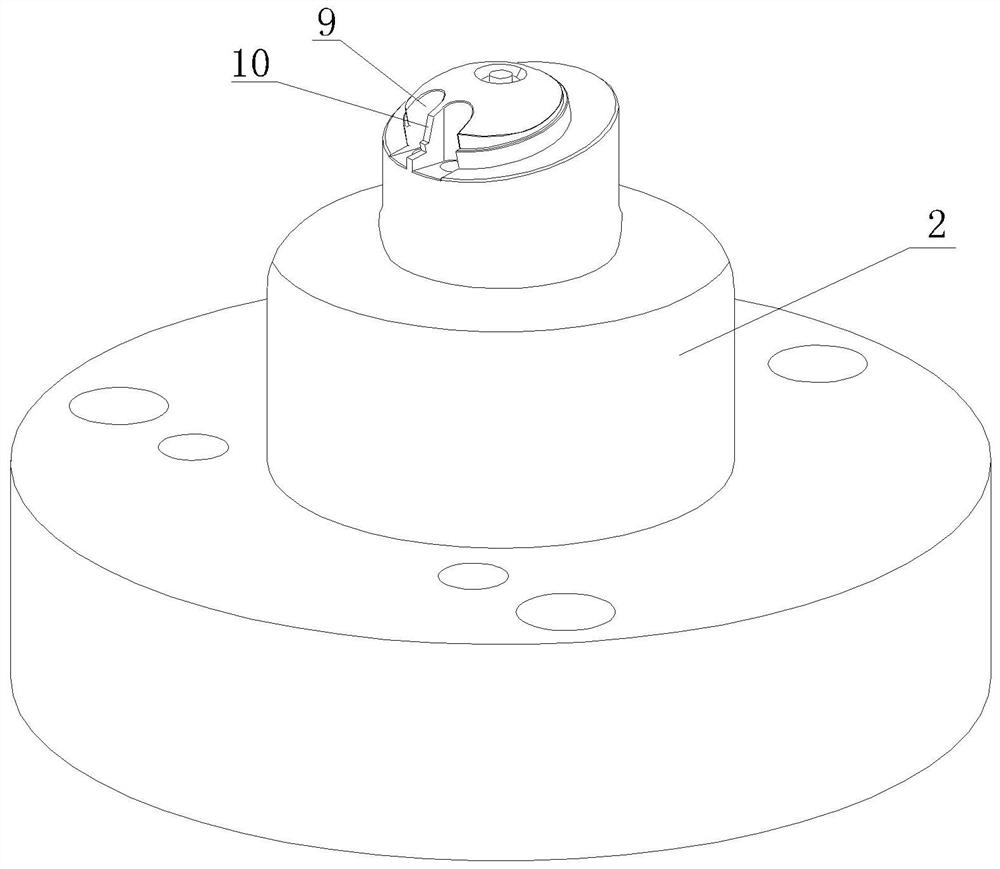

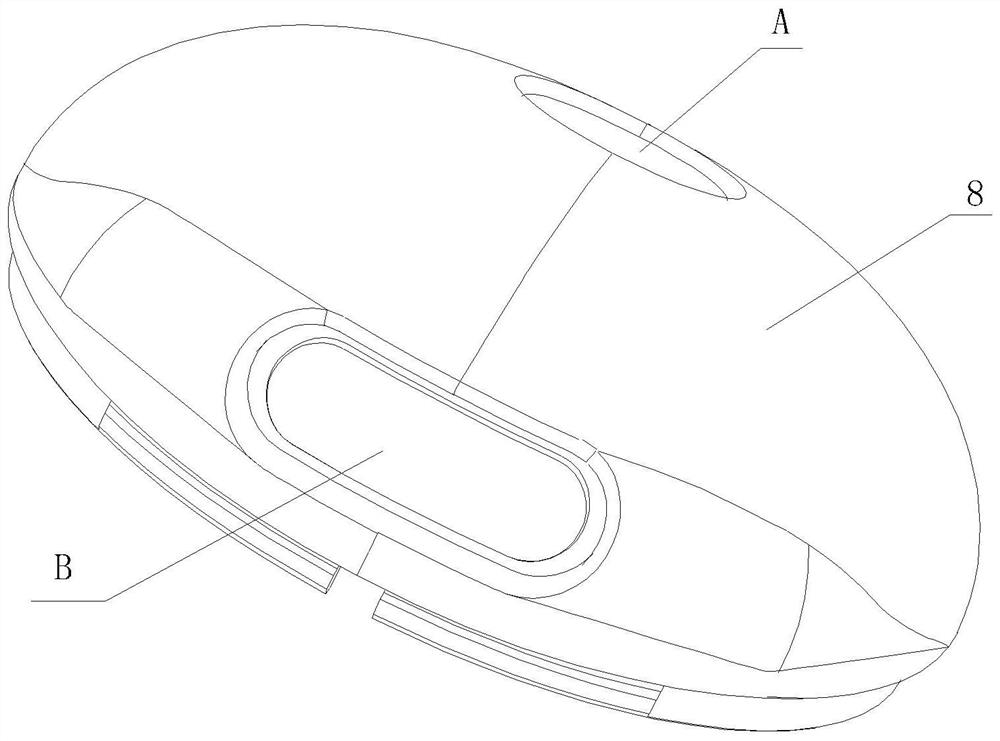

[0025] Embodiment 1 is basically as attached Figure 1-4 Shown: as figure 1 The ultrasonic high-precision and high-efficiency welding equipment shown includes welding cabinet 1, positioning seat 2, positioning seat adjustment assembly and two welding mechanisms; welding cabinet 1 includes upper and lower layers, and the lower layer is mainly used for installing ultrasonic cabinets, pressure reducing valves and For fan etc., the upper stratum is provided with two support seats 3 by screws, and certainly the positioning seat 2, the positioning seat adjustment assembly and two welding mechanisms are also installed on the upper strata.

[0026] The positioning seat adjustment assembly includes a frame body 4, a slide table 5, a bottom block 6 and a slide block 7, the bottom block 6 and the slide block 7 are in the shape of a right-angled trapezoid, and the bottom block 6 and the slide block 7 are all slidably arranged in the frame body 4; The slope of the bottom block 6 contacts ...

Embodiment 2

[0035] The difference from Embodiment 1 is that in this embodiment, the adjusting member includes a screw and a nut. Instead of a threaded hole 21, a through hole is opened on the adjusting fixing seat 20, and the screw rod is slidingly connected with the through hole. ; The left end of the screw rod is hinged with the adjusting pressing piece 19, specifically, a connecting rod in the shape of "]" is welded on the adjusting pressing piece 19, the length direction of the connecting rod points to the center of the adjusting pressing piece 19, and the left end of the screw rod is welded with a connection The connecting ring is sleeved on the connecting rod; the right end of the screw rod can be threadedly connected with the nut after passing through the through hole. When the position of the welding torch 14 and the sounder 12 is adjusted by turning the welding torch 14, the screw rod is locked directly through the nut. Since the nut is located outside the adjustment fixing seat 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com