A 5m-level weakly rigid tank bottom girth welding equipment

A circular seam welding and weak rigidity technology, applied in the field of storage tank bottom, can solve the problems of weldment deformation, weak rigidity of wall thickness, weak rigidity of large diameter tank bottom, etc., to achieve the effect of ensuring welding positioning accuracy and automatic circular seam welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

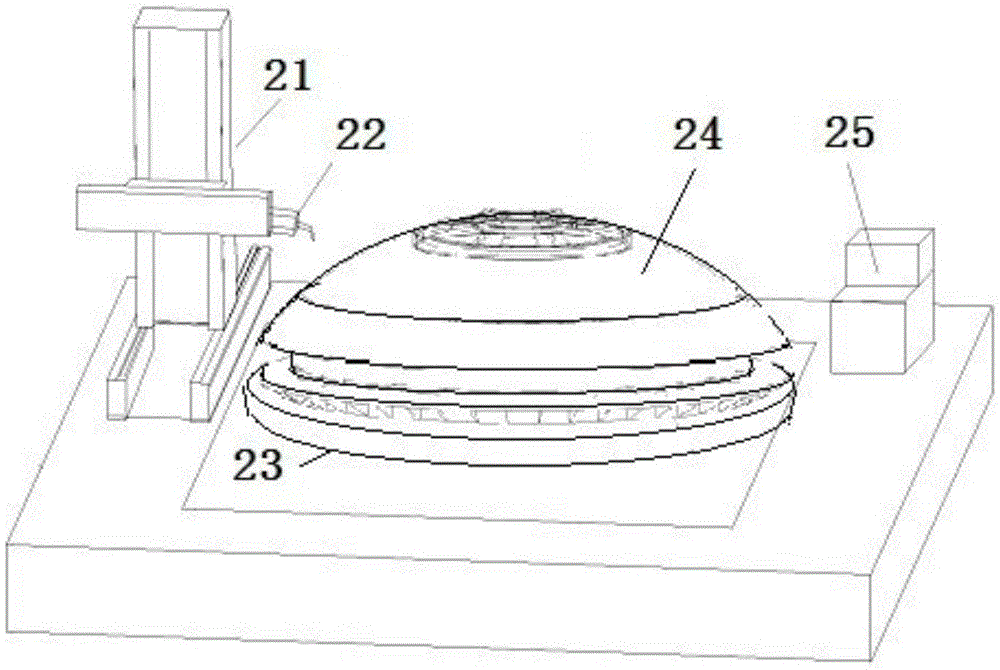

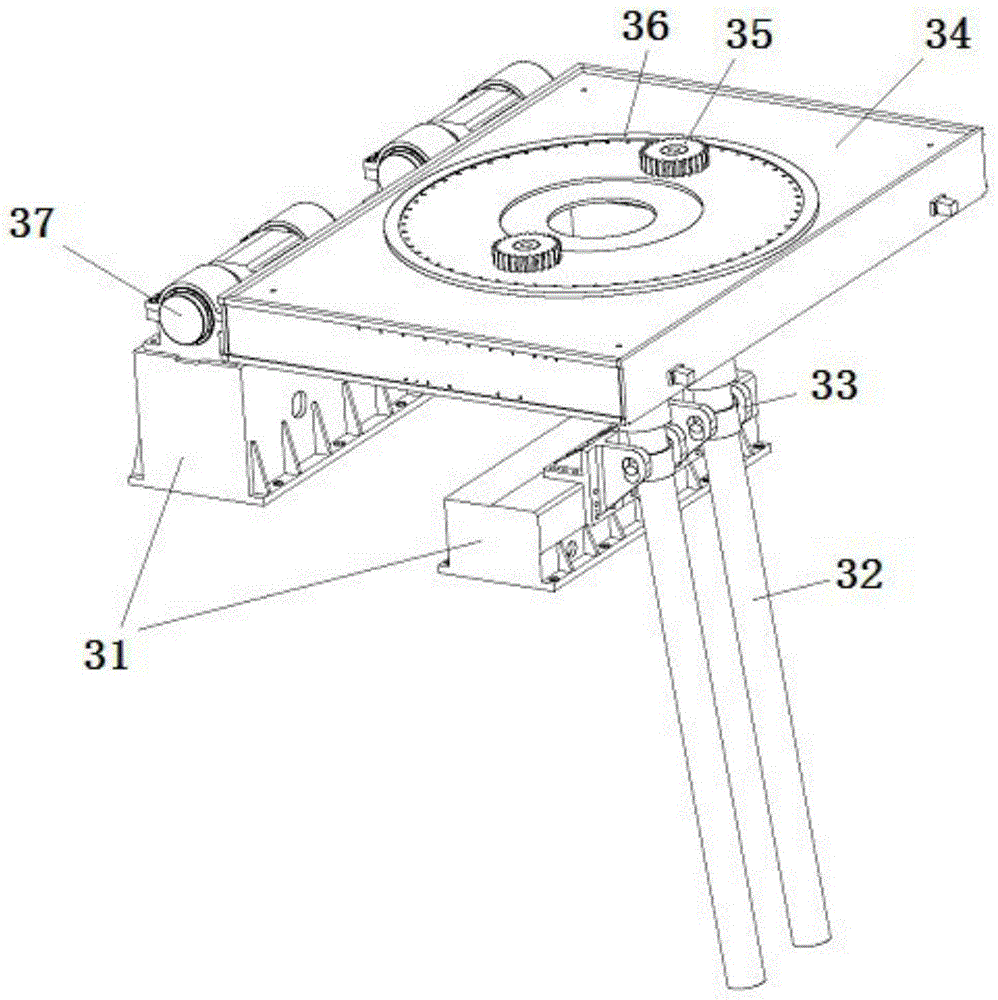

[0021] figure 2 It is a structural schematic diagram of a tank bottom girth seam welding equipment provided by an embodiment of the present invention. Such as figure 2 As shown, the tank bottom girth welding equipment includes: a welding bed 21 , a welding unit 22 , a rotating platform 23 and a welding mold tire 24 .

[0022] The welding bed 21 is fixed on the foundation, and can move along three-dimensional linear degrees of freedom, that is, reciprocate along the X-axis, Y-axis and Z-axis directions. At this time, since the welding unit 22 is arranged on the welding bed 21 , the welding unit 22 can be precisely positioned to any position in the three-dimensional space by adjusting the welding bed 21 .

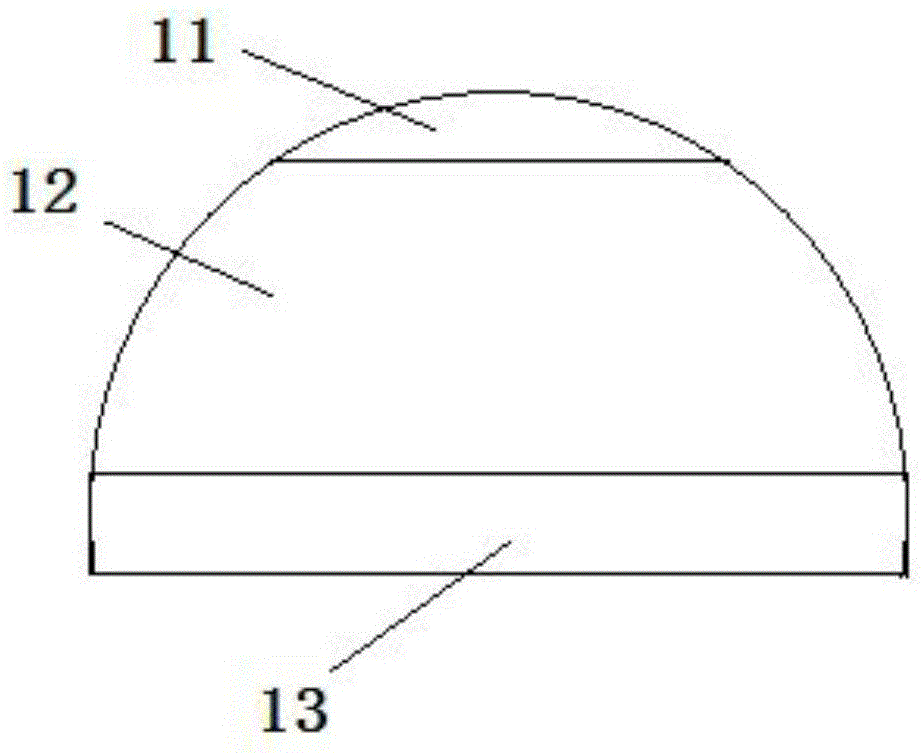

[0023] The top cover, the circular ring and the transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com