Combined preparation method of purple ultramarine pigment and pink ultramarine pigment

A technology of pink and ultramarine blue, applied in the field of joint preparation of purple ultramarine and pink ultramarine, which can solve the problem of lack of purple ultramarine and achieve the effect of simple process, convenient operation and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

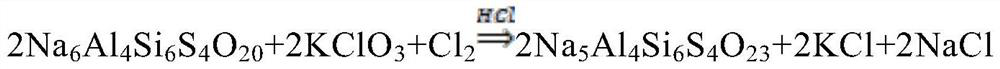

[0023] The present embodiment provides a kind of preparation method of purple ultramarine blue pigment, comprises the following steps:

[0024] (1) the blue ultramarine (Na 6 AL 4 Si 6 S 4 o 20 ) The dry powder is diluted in a porcelain vessel and placed in an acid-resistant stone furnace;

[0025] (2) After closing the kiln door and heating up to 245-255°C, add concentrated hydrochloric acid not less than one-tenth of the total weight of blue ultramarine and potassium chlorate solution not less than two-tenths of the total weight of blue ultramarine Pour into different porcelain plates, the concentration of concentrated hydrochloric acid is not less than 30%, the mass fraction of potassium chlorate solution is 10-15%, and the porcelain plate is placed in the kiln;

[0026] (3) Feed chlorine gas, keep the temperature in the kiln at 270-280°C, pay attention to observation or take more samples, and when the blue ultramarine starts to turn purple, lower the temperature to 19...

Embodiment 2

[0030] On the basis of embodiment 1, the present embodiment provides a kind of preparation method of pink ultramarine blue pigment, comprises the following steps:

[0031] (1) If the purple ultramarine obtained in step (3) of Example 1 is used to directly prepare pink ultramarine, then it is not necessary to take the purple ultramarine out of the furnace, and temporarily remove the hydrochloric acid and potassium chlorate in the furnace for reuse next time; if not directly prepare For pink ultramarine, purple ultramarine can be taken out of the oven first, washed and dried for later use. The specific operation of using purple ultramarine to prepare pink ultramarine is: put purple ultramarine and nitric acid with a mass fraction of 46-50% into two porous crucibles respectively, the weight of nitric acid is not less than three tenths of the total weight of purple ultramarine, and then Put it in an acid-resistant stone furnace, close the kiln door, and when it is ignited and heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com