Self-sealing instrument pipe fitting

An instrumentation tube, self-sealing technology, applied in the direction of pipe/pipe joint/pipe fitting, packing and sealing connection with fluid pressure, passing through components, etc., can solve the problems of easy leakage, insufficient strength, changing sealing strength, etc., to achieve self-sealing The effect of good effect, good sealing effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

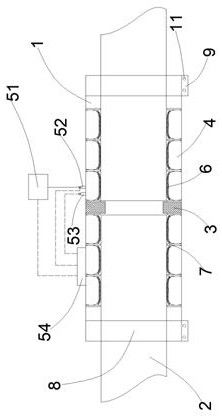

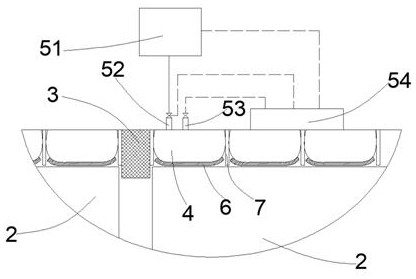

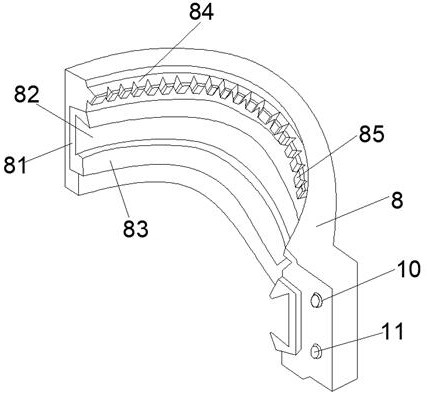

[0017] Example 1: see Figure 1~Figure 3 , A self-sealing instrument pipe fitting, an outer cylinder 1. Both ends of the outer cylinder 1 are respectively connected to a pipe 2. The pipe 2 is inserted into the outer cylinder 1, and a ring of abutment plates 3 are provided in the middle of the outer cylinder 1 A sealing device is provided on the inner wall of the outer cylinder 1 in contact with the pipe 2. The sealing device includes a number of airbag membranes 4, a pressurizing device 5 and a rubber sealing band 6, and the pressurizing device 5 is used to 4 Inflate and vent, the airbag membrane 4 is fixed on the inner wall of the outer cylinder 1, the rubber sealing band 6 is connected to the outer side of the airbag membrane 4, and the airbag membrane 4 is connected between two adjacent airbag membranes 4 through a partition 7 Separate; both ends of the outer cylinder 1 are provided with an unclosed sealing anti-off ring 8, the two ends of the sealing anti-off ring 8 are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com