Wide-angle distortionless lens based on aspheric surface

A distortion-free, aspheric technology, applied in the field of optical lenses, can solve the problems of increased cumulative error of lens components, high cost of mold opening, low production efficiency, etc., to achieve correction of redundant distortion aberrations, correction of residual aberrations, and excellent selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with accompanying drawing description:

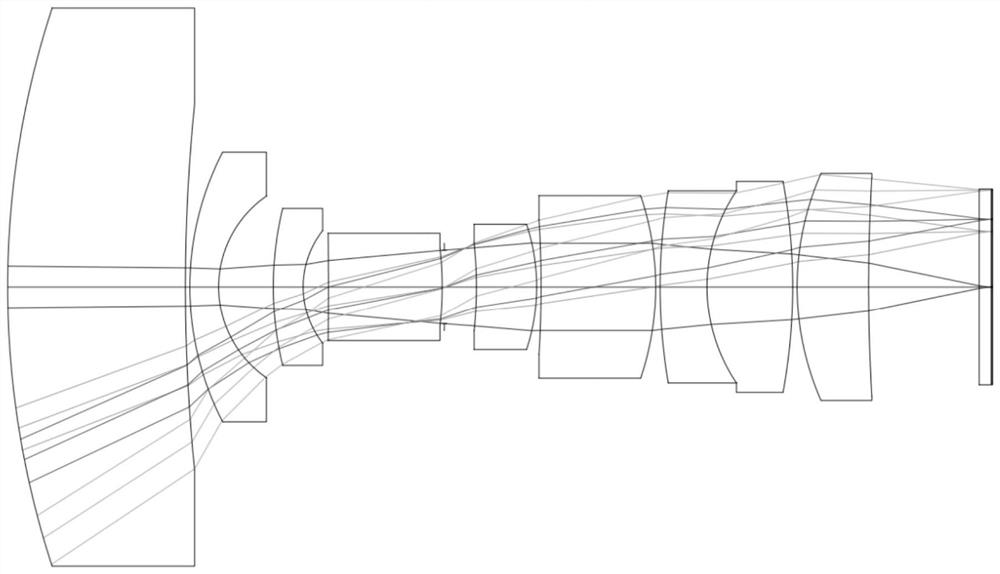

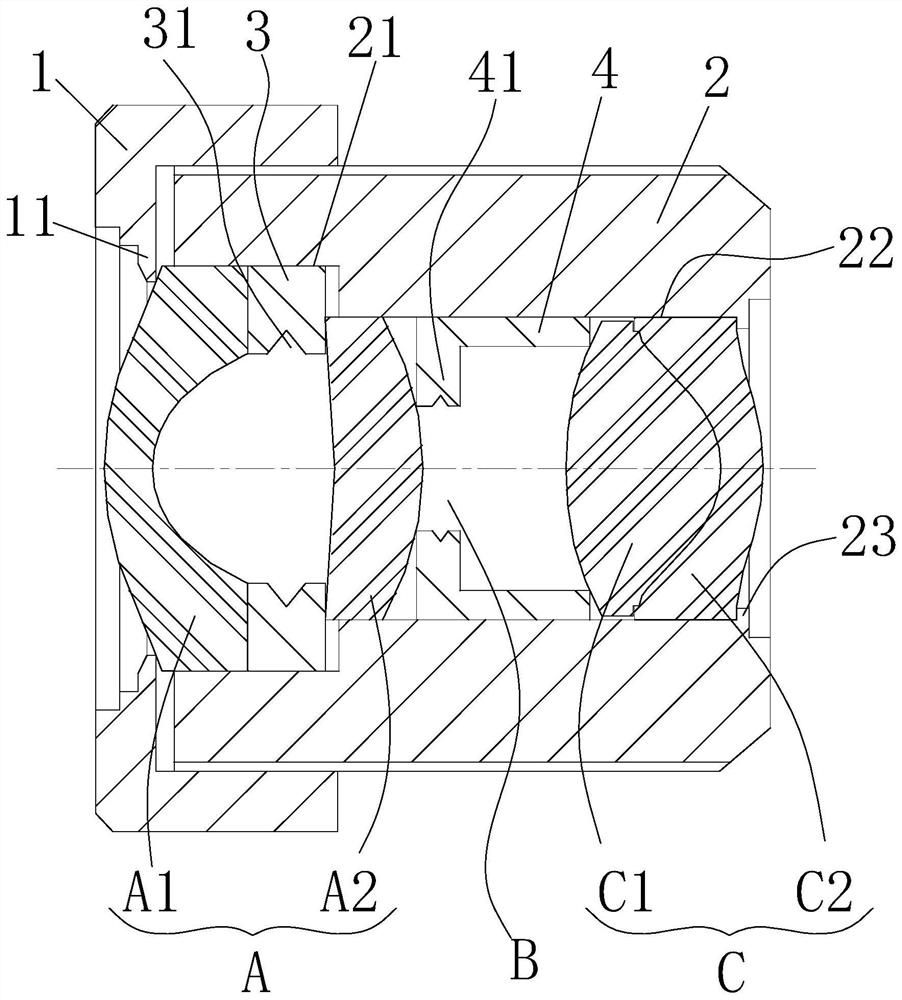

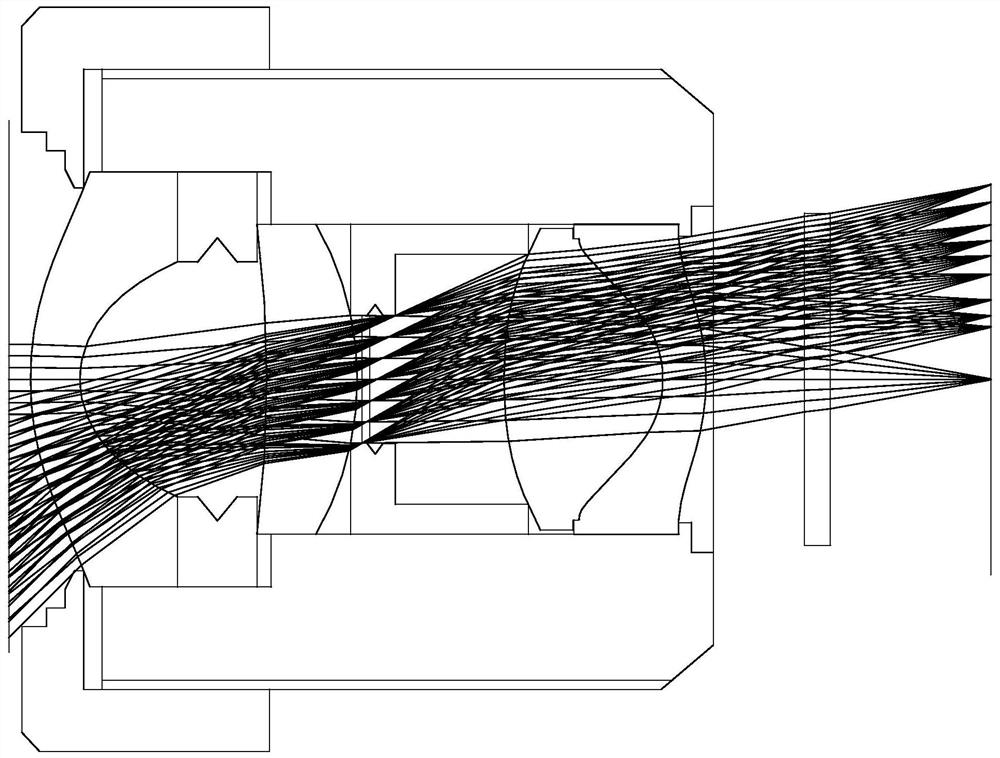

[0043] Such as Figure 2-7 As shown, a wide-angle distortion-free lens based on an aspheric surface is characterized in that: it includes a front mirror group A and a rear mirror group C arranged in sequence along the light incident direction, and there is a gap between the front mirror group A and the rear mirror group C. A fixed or variable diaphragm B is provided, the focal length of the front mirror group A is 20-35mm, and the focal length of the rear mirror group C is 3-5mm;

[0044] The front lens group A includes a first lens A1 and a second lens A2 arranged in sequence along the incident direction of light, and the rear lens group C includes a third lens C1 and a fourth lens C2 arranged in sequence along the incident direction of light. The first lens A1, the third lens C1 and the fourth lens C2 are all aspherical lenses, and the second lens A2 is a spherica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com