Method for forecasting ultimate bearing capacity of transmission shell under impact actoin of engine

A technology of transmission housing and impact action, applied in instruments, special data processing applications, geometric CAD, etc., can solve problems such as inability to meet product development needs, affecting product competitiveness, and various calculations, shortening product development cycles and saving energy. Humans judge the time and evaluate the effect accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

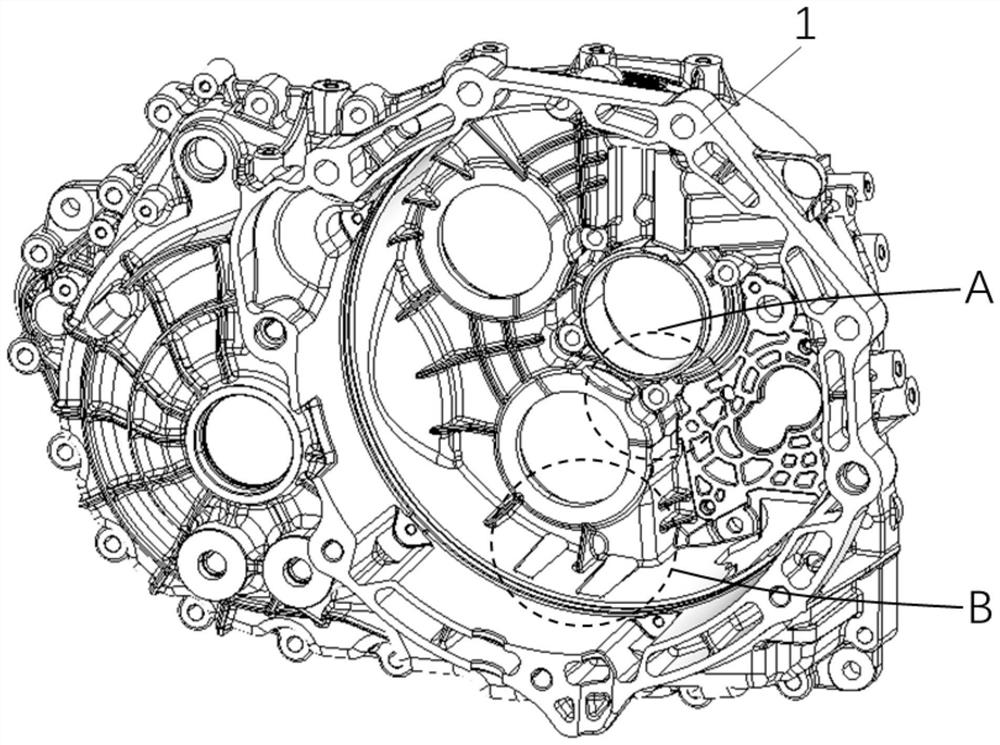

[0061] A method for predicting the ultimate bearing capacity of a transmission housing under the impact of an engine, comprising the following steps:

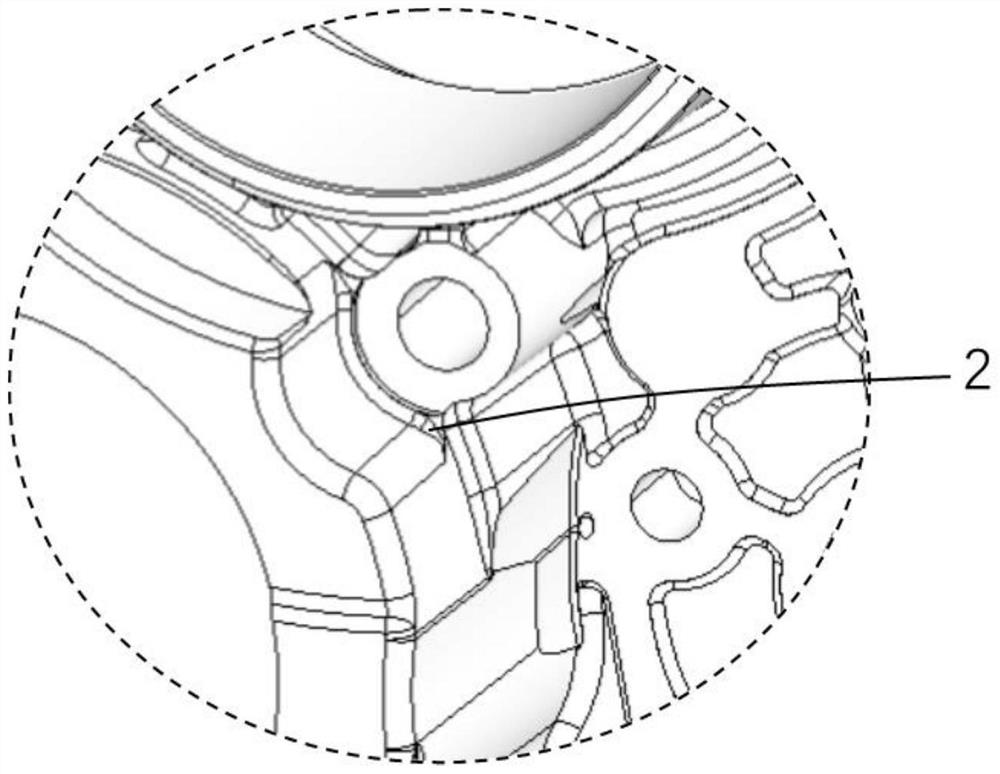

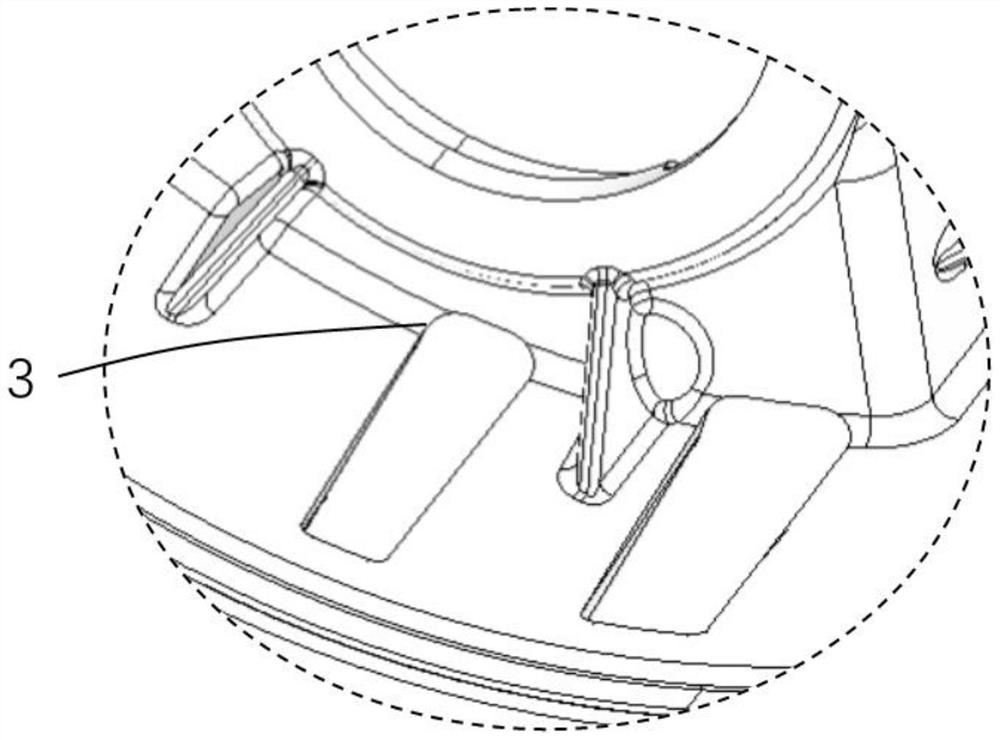

[0062] S1. Establish the finite element model of the transmission housing assembly: mesh the transmission housing, gear shaft, gears, bearings, differential, bolts, and bearing gaskets respectively, and then define the contact relationship between the contact parts They fit together.

[0063] S2. Define the material of the finite element model: the material of the transmission case is aluminum alloy, the elastic modulus E=71000MPa, Poisson’s ratio μ=0.33; the material of the differential case is ductile iron, E=17500MPa, Poisson’s ratio μ=0.3 ; Other materials are ferroalloy, E=210000MPa, Poisson's ratio μ=0.3.

[0064] S3. Apply finite element model load: according to the maximum output torque M of the engine e =200Nm, gear ratio and gear load calculation formula (1) Calculate the gear meshing force of any gear pair in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com