Drying device for tobacco primary processing

A drying device and silk-making technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of increased production cost, energy waste, etc., and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

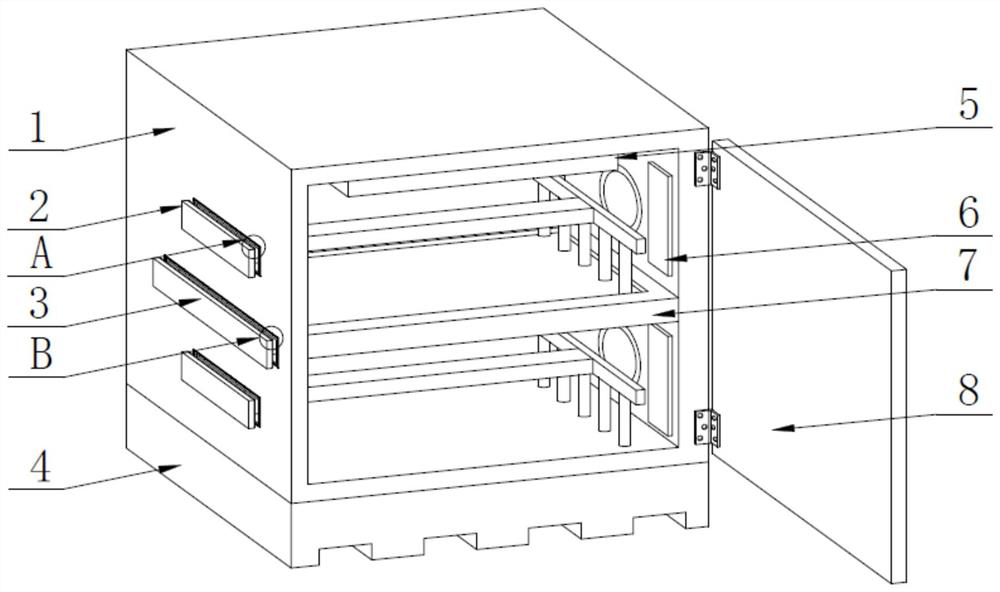

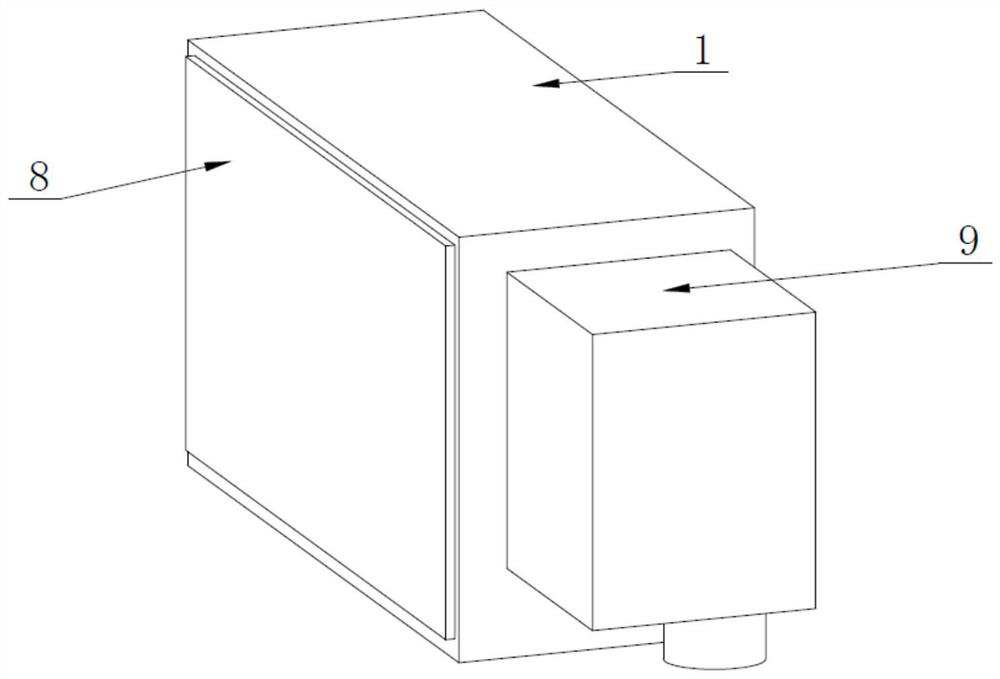

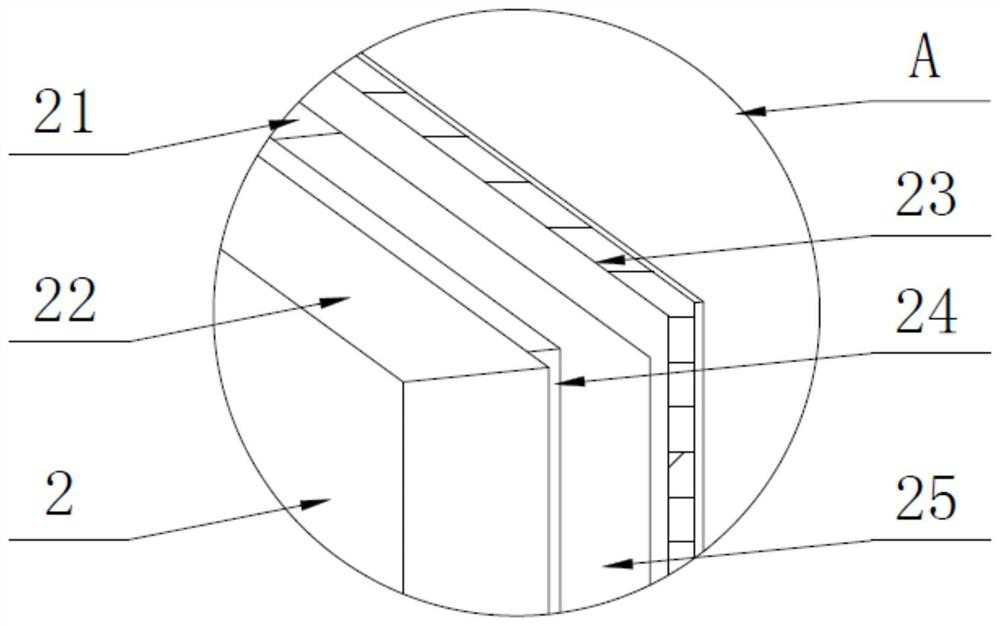

[0040] Such as figure 1 and figure 2 As shown, the present application provides a drying device for shredded tobacco, comprising a drying box 1, a box door 8 is hinged on the front surface of the drying box, and a partition plate 7 is fixedly connected to the middle position inside the drying box. , A heating element is installed in the drying box.

[0041] A base 4 is integrally installed at the bottom of the drying box 1 . In the technical solution of this application, the left side and the right side are relative concepts, which can be interchanged according to actual needs, and will not affect the realization of the technical so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com