Gas tightness detection and replacement device for glass curtain wall

A technology of air tightness detection and glass curtain wall, which is applied in liquid tightness measurement using liquid/vacuum degree, by measuring the increase and deceleration rate of the fluid, hand-held tools, etc. Safety, glass fragments falling from high altitude and other issues, to avoid the danger of high-altitude operations, improve the working environment, and prevent the effect of glass falling and hurting people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

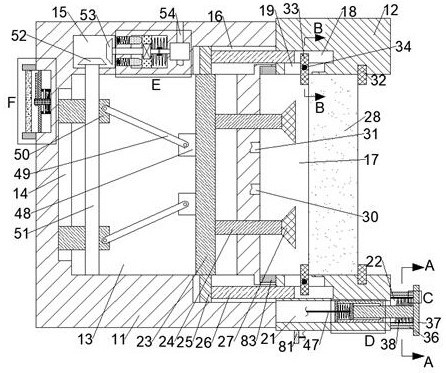

[0023] Combine below Figure 1-Figure 8 The present invention will be described in detail. For the convenience of description, the following directions are specified as follows: figure 1 The vertical, horizontal, front, and rear directions of the projection relationship are the same.

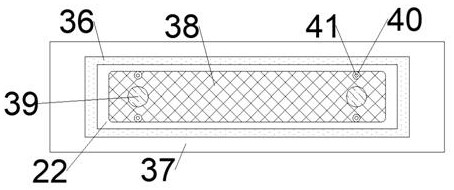

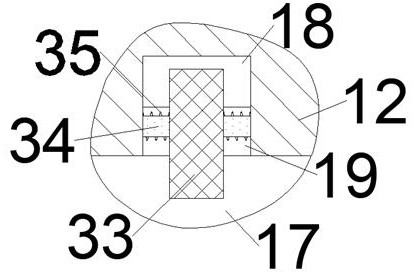

[0024] The device for detecting and replacing the airtightness of a glass curtain wall according to the present invention includes a body 11 in which a disassembly cavity 13 is provided, and a disassembly plate 23 that can slide left and right is provided in the disassembly cavity 13. The right end surface of the body 11 is symmetrically provided with a horizontal frame 12 forming a seal. A curtain wall glass 28 is fixed between the upper and lower horizontal frames 12. The horizontal frame 12, the curtain wall glass 28 and the right end surface of the body 11 A sealed detection chamber 17 is formed between the body 11 and the left end of the detection chamber 17. A sealing ring 83 is fixed between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com