A wire extruder head cleaning device

A cleaning device and extruder technology, applied in the direction of conductor/cable insulation, etc., can solve the problems of low efficiency, poor effect, difficult to remove, etc., achieve good effect, reasonable structure, ensure quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

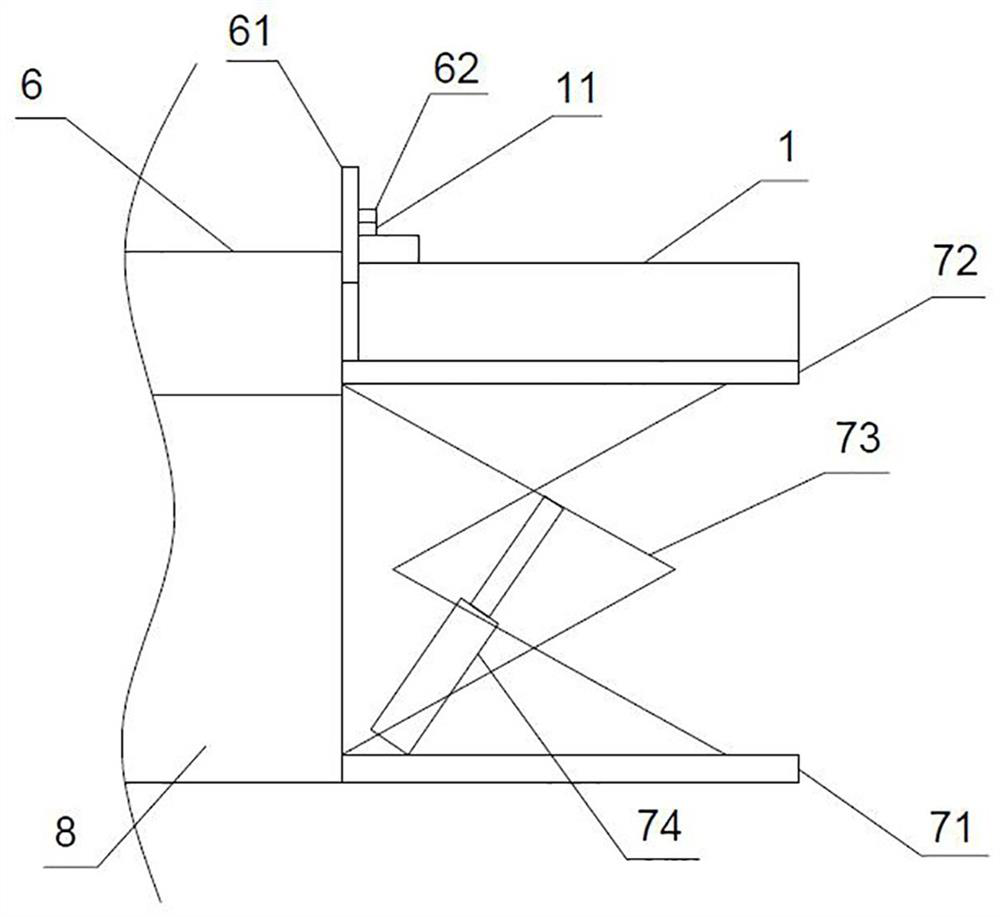

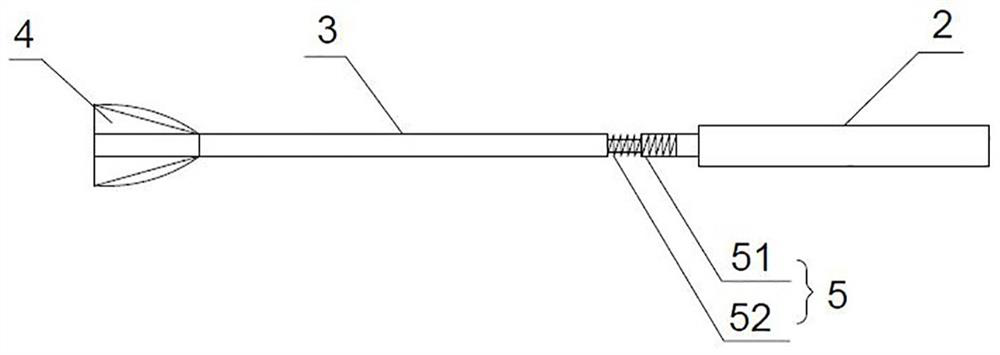

[0026] A cleaning device for the head of a wire extruder, comprising a lifting platform and a telescopic cleaning mechanism arranged on the lifting platform. The telescopic cylinder 2, the air blow gun 3 connected to the output end of the telescopic cylinder 2 and stretched in the telescopic channel, the air blow gun 3 is provided with an air source by an air compressor or a compressed gas cylinder; the side surface of the air blow gun 3 near the gas outlet A plurality of scraper blades 4 are provided, and adjacent scraper blades 4 are alternately arranged, and the scraper blades 4 are arranged obliquely toward the air outlet side of the blow gun, and the scraper blades 4 are in the shape of an arc bent outward.

[0027] The working principle of this device: When the extruder is working normally, the lifting table is at the lowest sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com