Assembly line weighing and packaging table with chain type plate scale

An assembly line and packaging platform technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of reduced production efficiency, time-consuming and laborious, sensor damage, etc., and achieve the effect of avoiding monitoring errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

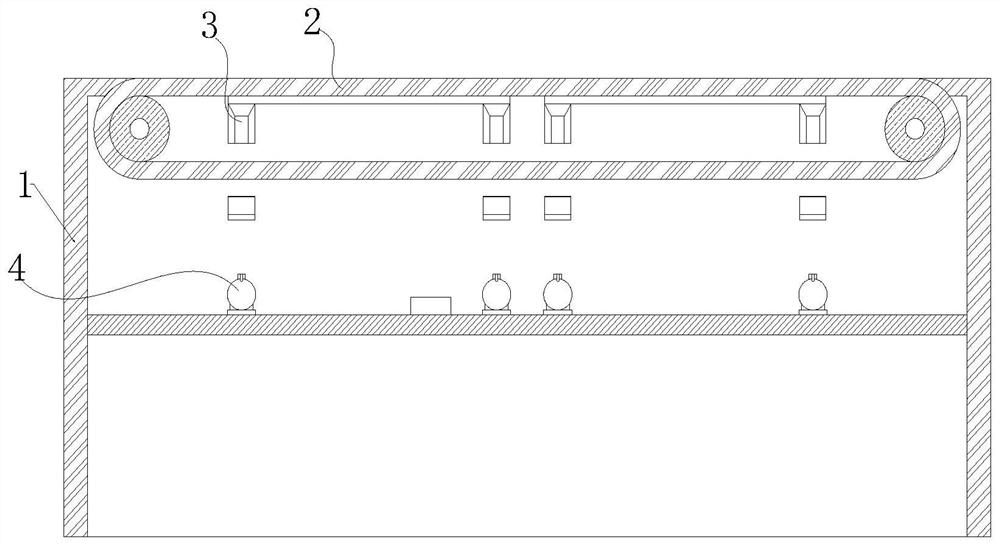

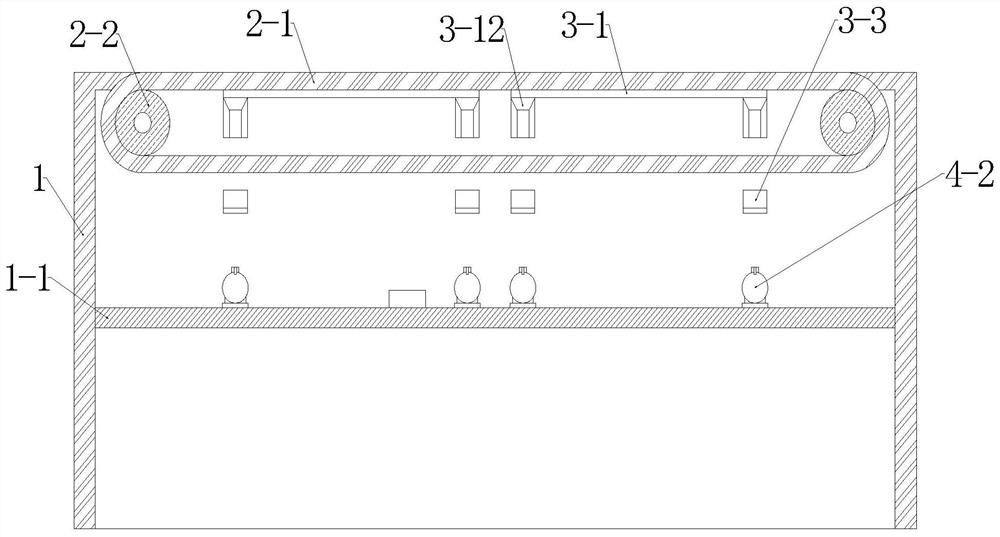

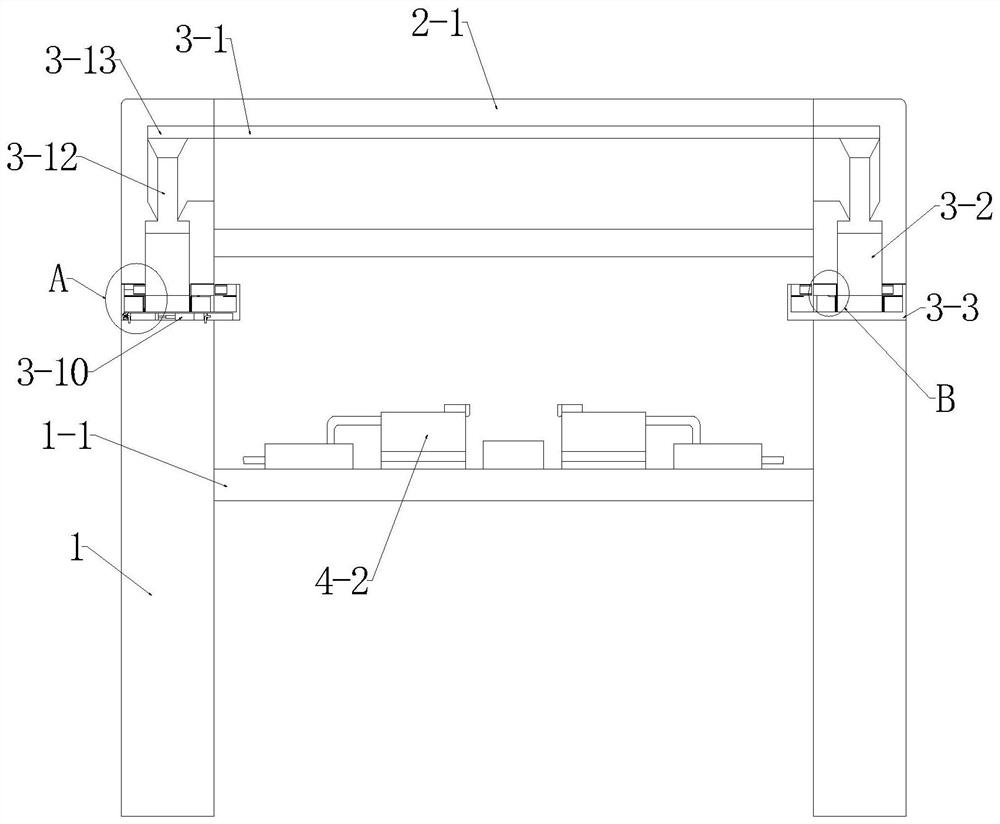

[0040] Example: such as Figure 1-12 As shown, the assembly line weighing and packaging platform with chain plate scales includes a bracket 1, a transmission mechanism 2, two sets of weighing mechanisms 3, and two sets of pressure maintenance components 4. The transmission is installed on the bracket 1. Mechanism 2, a support plate 1-1 is welded at the middle position inside the bracket 1, and a controller is also arranged on the support plate 1-1, the controller is electrically connected with the transmission mechanism 2, the weighing mechanism 3 and the pressure maintenance component 4, and the two The group weighing mechanism 3 is installed in the middle of the transmission mechanism 2. The weighing mechanism 3 can weigh the heavy objects on the transmission mechanism 2 through the change of air pressure. The two groups of pressure maintenance components 4 make the air volume in at least two groups of weighing mechanisms 3 constant.

[0041] Transmission mechanism 2 compri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com