Low speed bucket elevator automatic material discharging device

A bucket elevator and automatic discharge technology, which is applied to packaging, conveyor objects, transportation and packaging, etc., can solve the problems of uneven feeding and automatic discharge of materials, and achieve the effect of convenient transportation and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

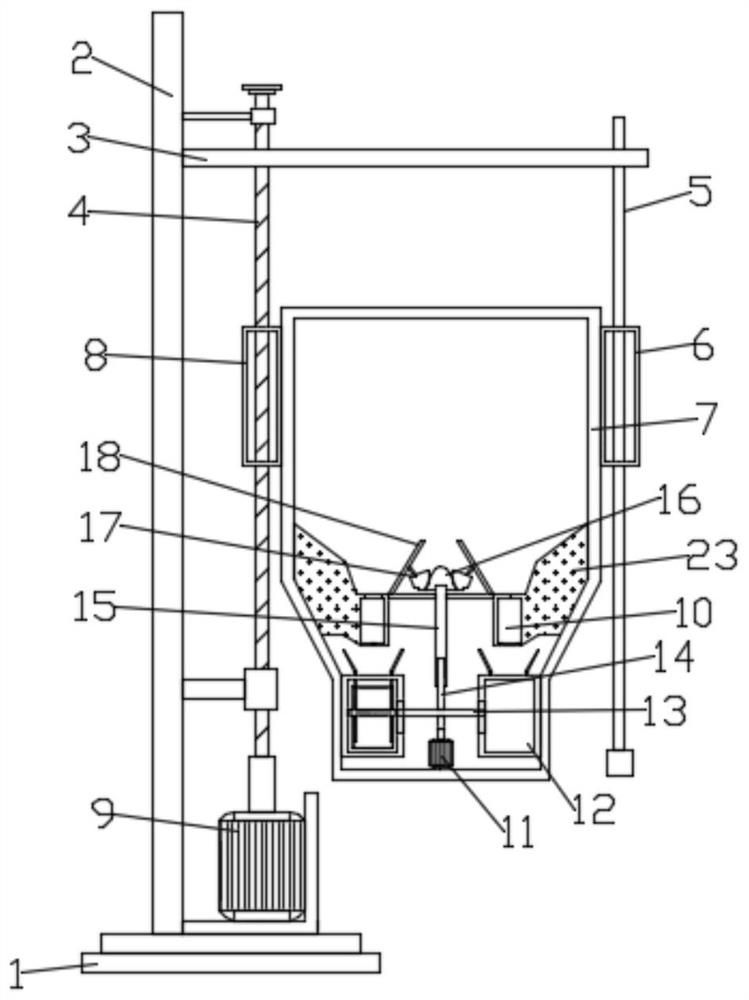

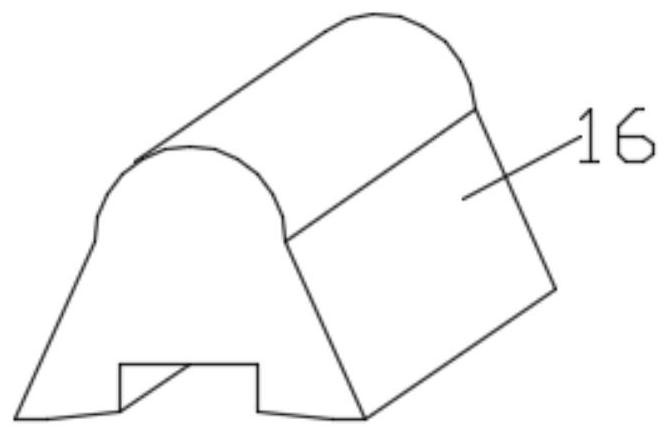

[0020] Such as figure 1 As shown, in the embodiment of the present invention, a low-speed bucket elevator automatic discharge device includes a base 1 and a support column 2. The support column 2 is fixedly installed on the base 1, and a hopper 7 is provided on one side of the support column 2. The base 1 is provided with a lifting mechanism for adjusting the position of the hopper 7, and the bottom of the hopper 7 is symmetrically provided with two feeding pipes 12, the feeding pipe 12 is provided with a discharge assembly, and a driving assembly is provided between the feeding pipes 12;

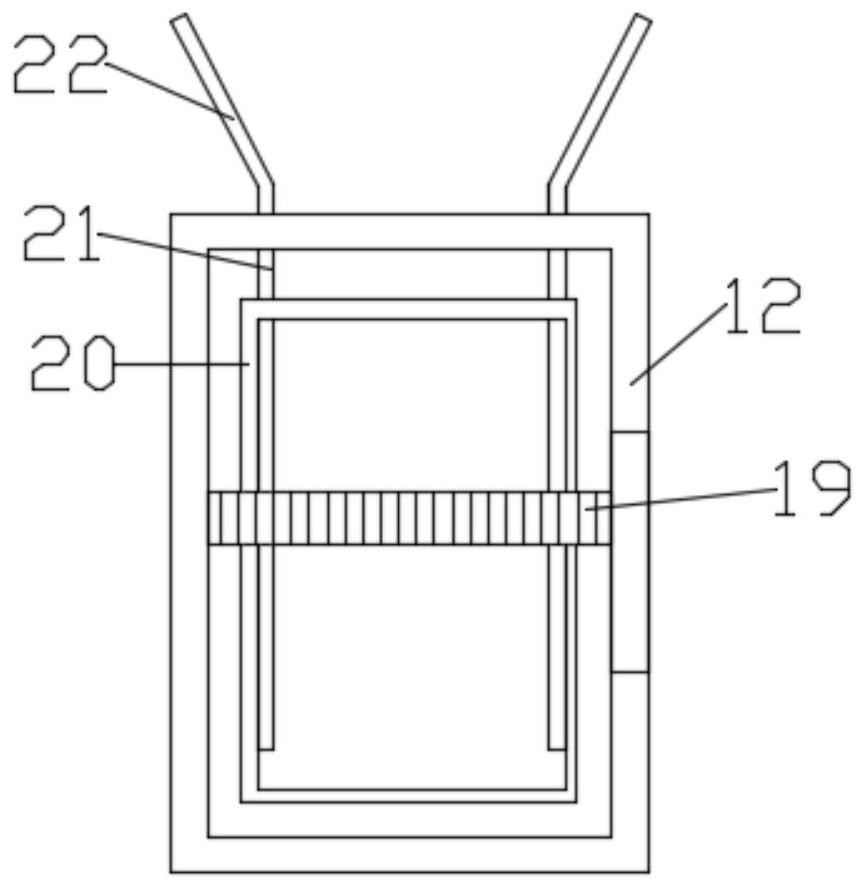

[0021] The driving assembly includes a second working motor 11, a driving gear 13 and a second screw rod 14, the second working motor 11 is fixed on the bottom of the hopper 7, and the output end of the second working motor 11 is fixedly connected with a second screw rod 14, the second screw rod The fixed cover in the middle part of 14 is provided with driving gear 13, and the top cover of ...

Embodiment 2

[0030] Such as figure 1 As shown, in the embodiment of the present invention, a low-speed bucket elevator automatic discharge device includes a base 1 and a support column 2. The support column 2 is fixedly installed on the base 1, and a hopper 7 is provided on one side of the support column 2. The base 1 is provided with a lifting mechanism for adjusting the position of the hopper 7, and the bottom of the hopper 7 is symmetrically provided with two feeding pipes 12, the feeding pipe 12 is provided with a discharge assembly, and a driving assembly is provided between the feeding pipes 12;

[0031] The driving assembly includes a second working motor 11, a driving gear 13 and a second screw rod 14, the second working motor 11 is fixed on the bottom of the hopper 7, and the output end of the second working motor 11 is fixedly connected with a second screw rod 14, the second screw rod The fixed cover in the middle part of 14 is provided with driving gear 13, and the top cover of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com