Electric loader synchronized with cable winch

A technology of cable winches and loaders, which is applied to earth movers/excavators, construction, etc., can solve the problems of loaders such as inconvenience, out-of-synchronization, and out-of-sync travel direction and speed, and achieve the effect of convenient placement and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

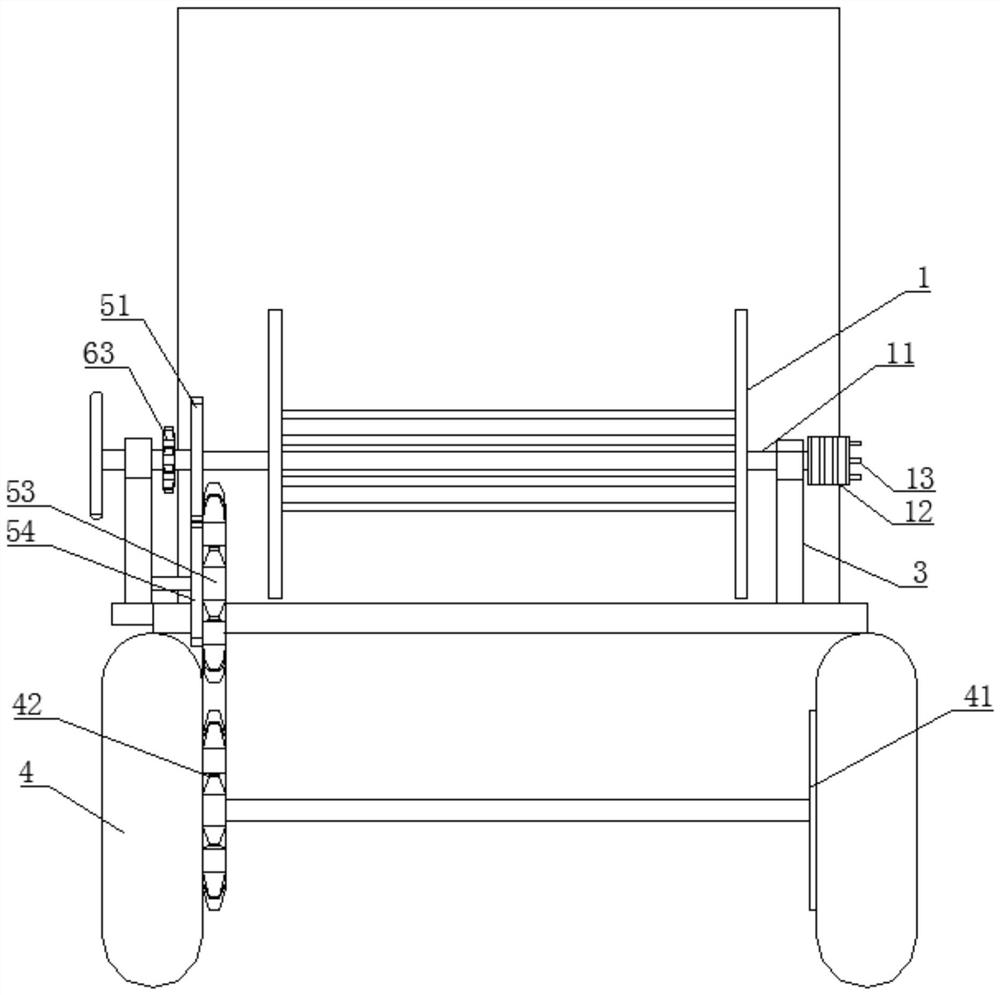

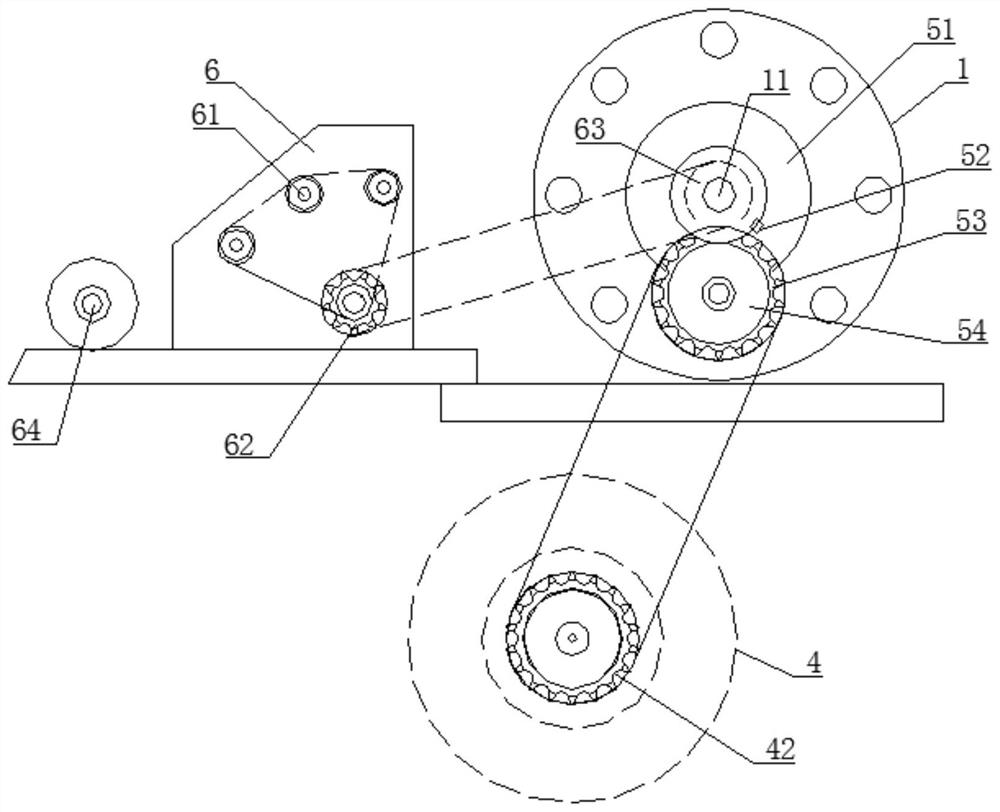

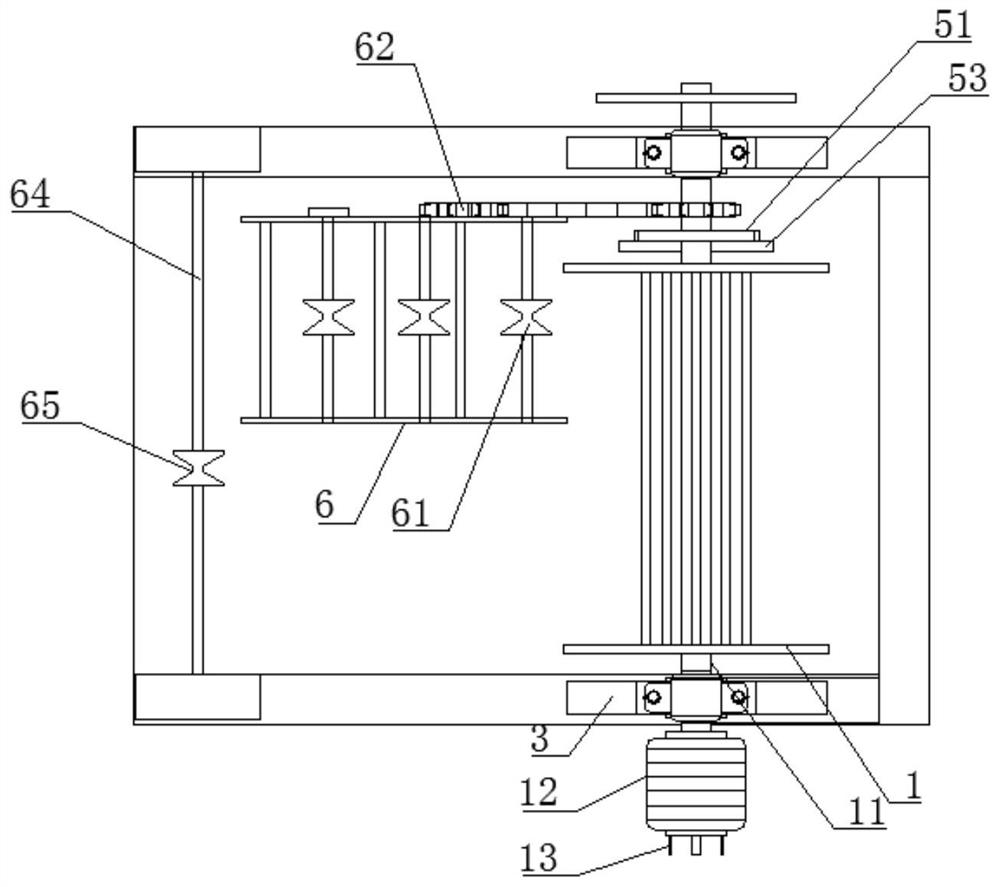

[0025] like Figure 1 to Figure 3 Commonly shown, a cable winch synchronous electric loader includes a cable winch 1 for winding cables, the cable winch 1 has a rotating shaft 11, and the two ends of the rotating shaft 11 are rotatably mounted on the support frame 2, and the support frame 2 is installed On the rear frame 3 of the loader.

[0026] The inner side of the rear wheel 4 of the loader is provided with a ring gear 42 which is fixedly connected to the wheel rim 41 and rotates synchronously. The ring gear 42 rotates synchronously with the rotating shaft 11 through the first transmission mechanism.

[0027] One end of the rotating shaft 11 is equipped with a synchronously rotating brake caliper disc 51 and a brake 52 that hinders the rotation of the rotating shaft. The brake 52 is controlled by the braking system of the loader. The control air circuit of the loader is connected in parallel with the control air circuit of the brake of the loader, when the brake pedal of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com