Double-flap jacking type sucker rod workover operation power slip and operation process

A technology for power slips and sucker rods, which is applied to drill pipes, drilling equipment, earth-moving drilling, etc., can solve the problems of high labor occupation, high labor intensity, and high safety risks, and achieve the effect of improving efficiency and realizing automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

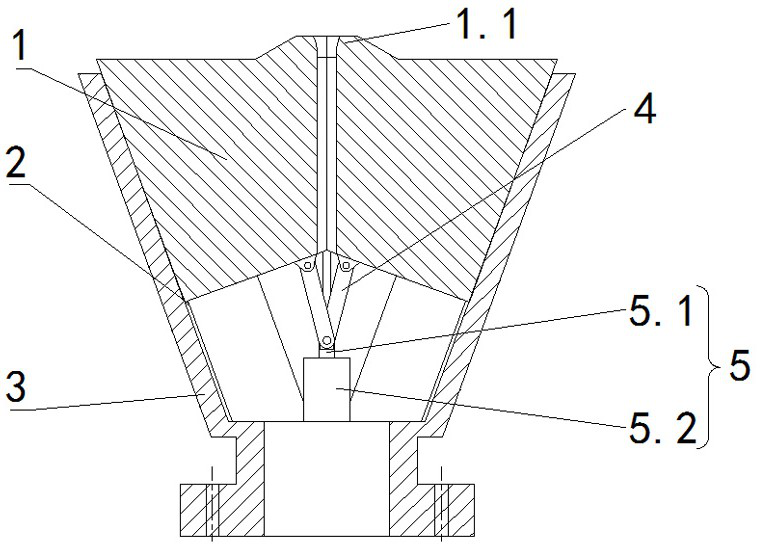

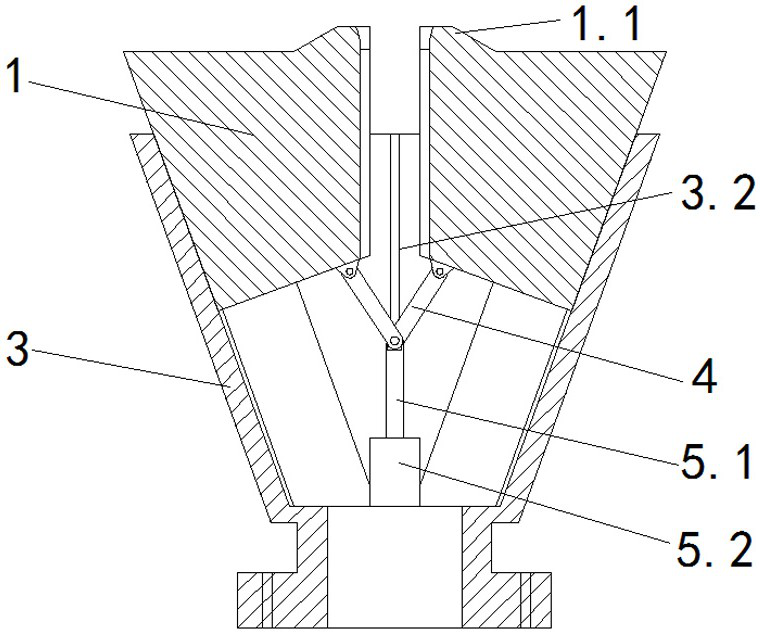

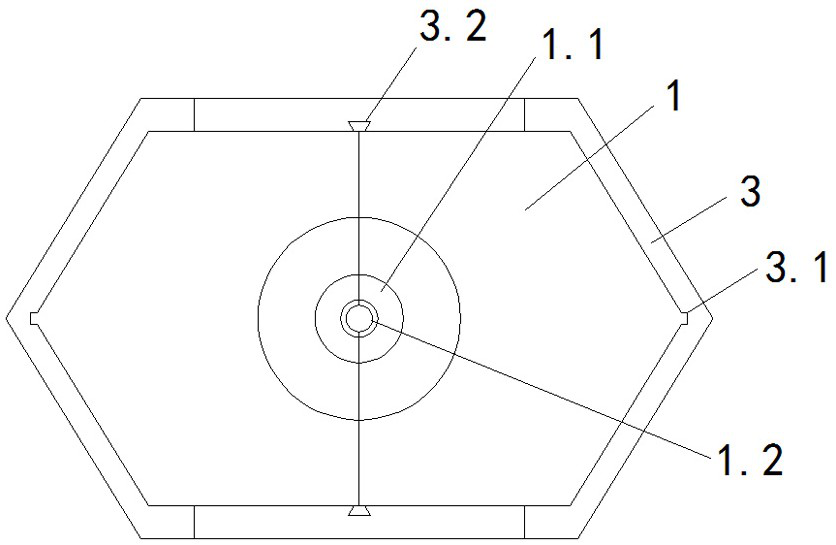

[0025] Embodiment 1, with reference to figure 1 with 2 , a double-lobe jacking type sucker rod workover operation power slip mentioned in the present invention, including a sucker rod holding unit 1, a follow-up sealing device 2, a power slip box 3, a connecting rod 4, and a hydraulic cylinder 5. The double-lobe jacking type sucker rod workover power slips are integrally installed on the small cross 7, and the elevator 6 is installed on the top of the double-lobe jacking type sucker rod workover power slips. The slip box 3 is installed with the hydraulic cylinder 5, the connecting rod 4, and the sucker rod support unit 1 sequentially from bottom to top, and the hydraulic cylinder 5 is divided into two groups and located at the front and rear symmetrical positions inside the power slip box 3. The cylinder 5 includes a hydraulic cylinder piston 5.1 and a hydraulic cylinder body 5.2. The upper ends of the hydraulic cylinder piston 5.1 are respectively connected to the bottoms of...

Embodiment 2

[0038] Embodiment 2, a double-lobe jacking type sucker rod workover operation power slip mentioned in the present invention, including a sucker rod holding unit 1, a follow-up sealing device 2, a power slip box 3, and a connecting rod 4 , the hydraulic cylinder 5, the double-lobe jacking type sucker rod workover operation power slips are integrally installed on the small cross 7, and the elevator 6 is installed on the top of the double-lobe jacking type sucker rod workover operation power slips, The power slip box 3 is sequentially installed with a hydraulic cylinder 5, a connecting rod 4, and a sucker rod holding unit 1 from bottom to top, and the hydraulic cylinders 5 are divided into two groups and located at front and rear symmetrical positions inside the power slip box 3, The hydraulic cylinder 5 includes a hydraulic cylinder piston 5.1 and a hydraulic cylinder body 5.2. The upper ends of the hydraulic cylinder piston 5.1 are respectively connected to the bottom of the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com