Pneumatic tire

A pneumatic tire, tire circumferential technology, applied to tire parts, tire tread/tread pattern, vehicle parts, etc., can solve the problem of large change in the area of the front-end wire groove on the ground, to suppress pattern noise, suppress pattern Noise generation, effect of pattern noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

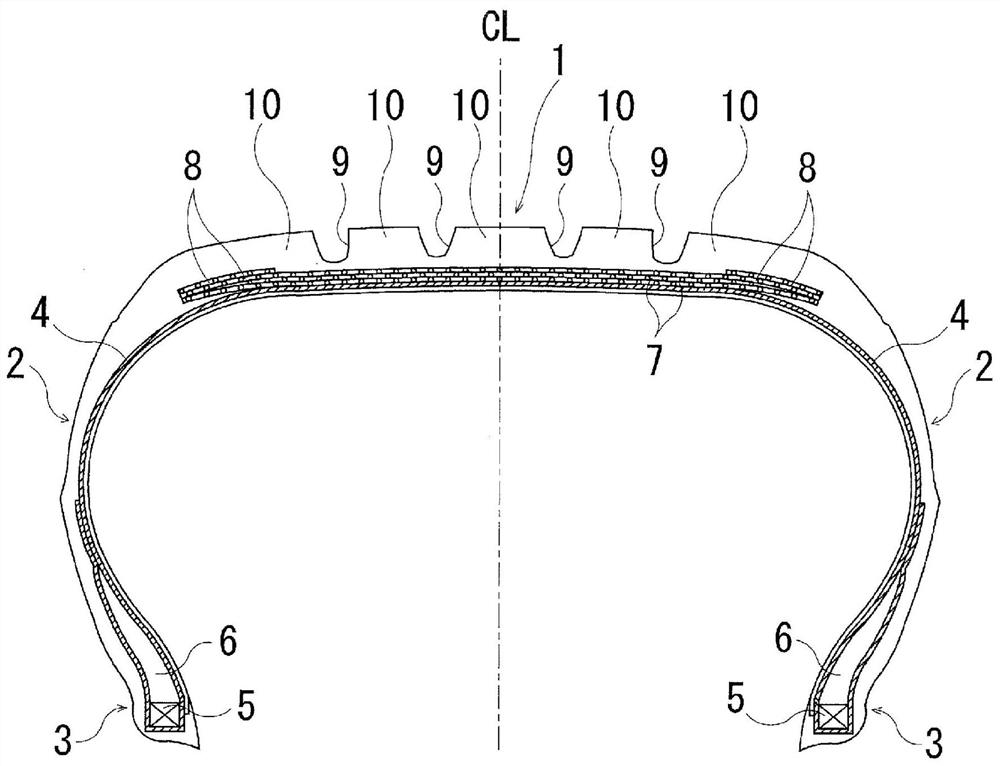

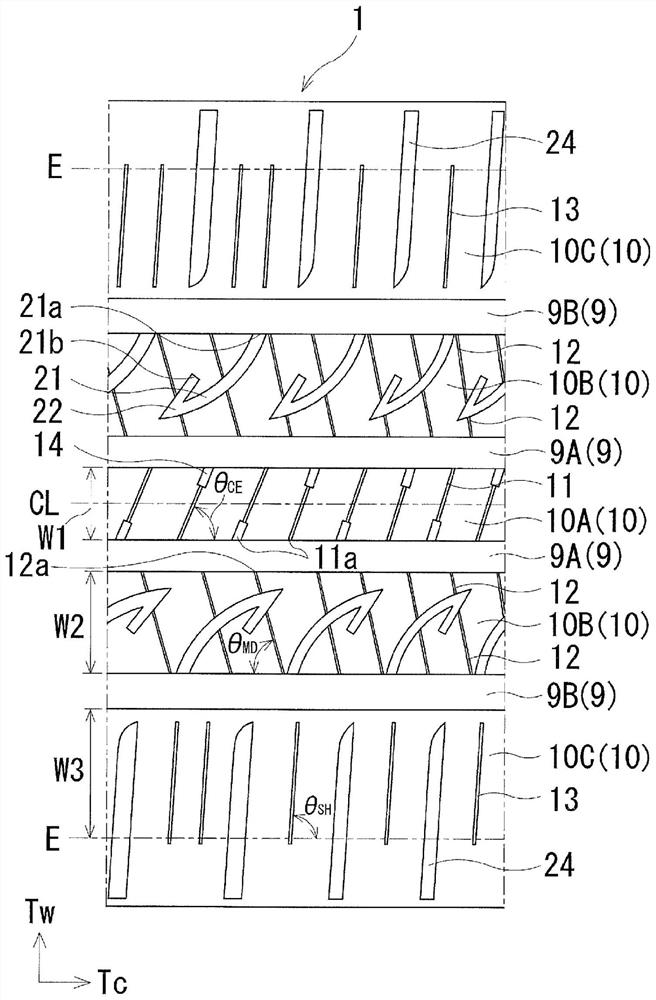

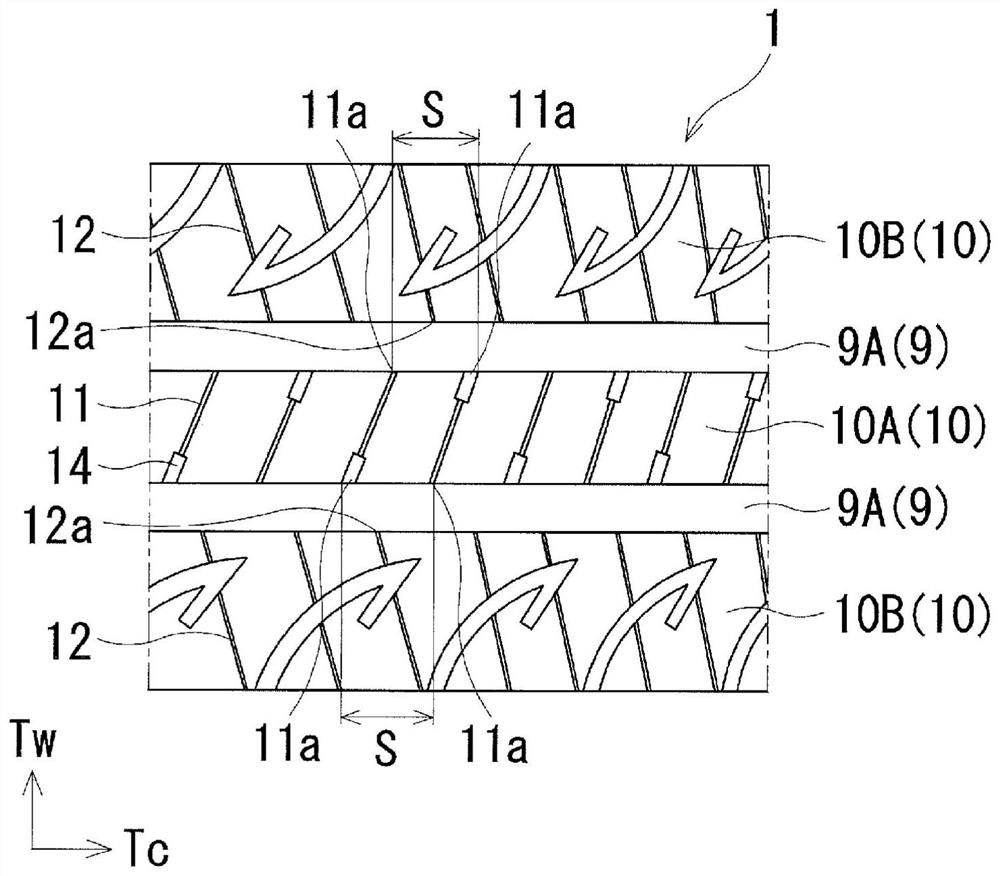

[0041] With the tire size 225 / 50R18, the tires of Examples 1-6 were produced, and these tires were equipped with: a tread portion extending in the tire circumferential direction and forming a ring shape; a pair of sidewall portions arranged on both sides of the tread portion; and a The bead portion is disposed on the inner side in the tire radial direction of these sidewall portions, and four main grooves including a pair of inner main grooves and a pair of outer main grooves extending in the tire circumferential direction are provided on the tread portion, and are divided by these main grooves. Out of the central land portion, a pair of intermediate land portions located outside the central land portion, and a pair of shoulder land portions located outside the intermediate land portion, wherein the central land portion, the intermediate land portion, and the shoulder land portions are respectively A plurality of sipes are provided at intervals in the circumferential direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com