Alfalfa seed treatment method for improving stress resistance

A technology for alfalfa and seed treatment, which is applied in the fields of seed and rhizome treatment, botany equipment and methods, seed coating/seed dressing, etc. It can solve the problems of little research on the stress resistance of alfalfa seeds, and achieve large-scale social promotion value, improving salt stress tolerance, and improving stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

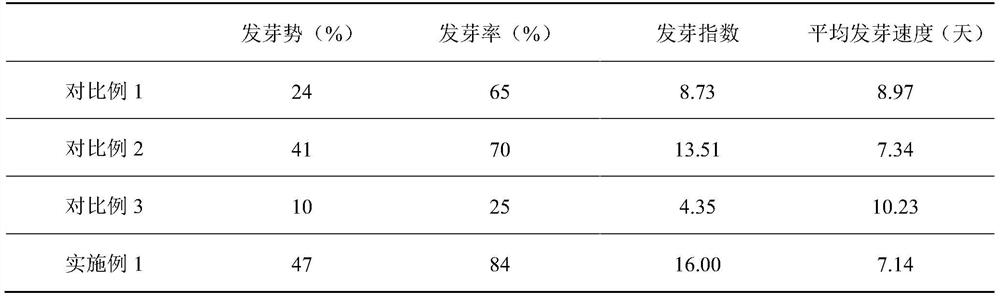

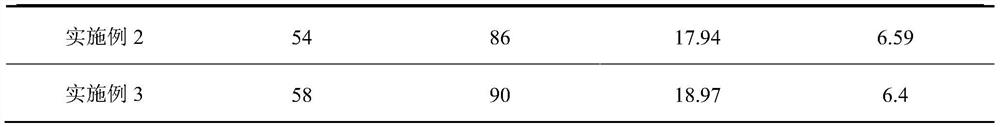

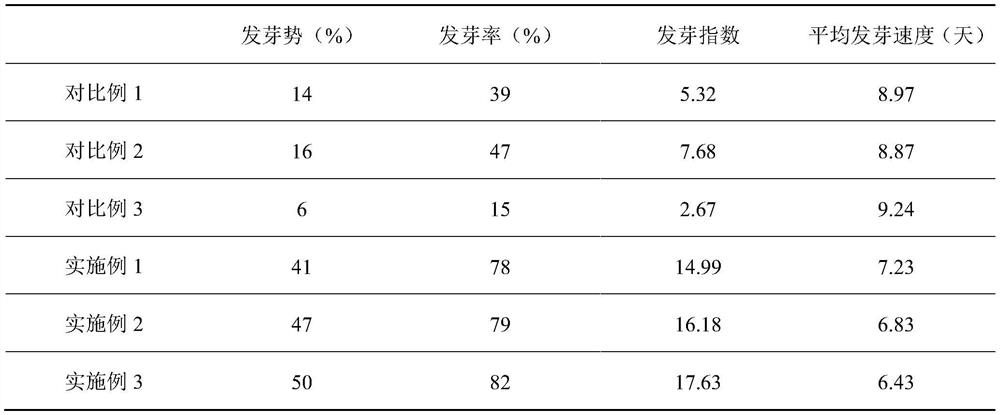

Embodiment 1

[0023] A method for treating alfalfa seeds that improves stress resistance, comprising the following steps:

[0024] (1) Mix fine sand 8: alfalfa seeds 1 according to the mass portion ratio and pack into a metal container for sealing, wherein the particle diameter of the fine sand is 0.8mm;

[0025] (2) Place the metal container filled with fine sand and alfalfa seeds in step (1) on a vibration aging platform and vibrate for 30 minutes, wherein the frequency of vibration aging is the metal container filled with fine sand and alfalfa seeds obtained by the equipment according to scanning. The natural frequency of the container is determined;

[0026] (3) the fine sand and the alfalfa seed mixture obtained in step (2) after vibration aging are sieved to separate the alfalfa seeds and then soaked in distilled water for 48h to drain the water; 1.4mm, so choosing a suitable sieve can filter out the dry alfalfa seeds while removing the fine sand, leaving only the plump seeds.

[00...

Embodiment 2

[0037] A method for treating alfalfa seeds that improves stress resistance, comprising the following steps:

[0038] (1) Mix fine sand 10 according to the mass part ratio: alfalfa seed 1 and pack into a metal container for sealing, wherein the particle diameter of the fine sand is 1.0mm;

[0039] (2) Place the metal container filled with fine sand and alfalfa seeds in step (1) on a vibration aging platform and vibrate for 40 minutes, wherein the frequency of vibration aging is the metal container filled with fine sand and alfalfa seeds obtained by the equipment according to scanning. The natural frequency of the container is determined;

[0040] (3) the fine sand and the alfalfa seed mixture obtained in step (2) after vibration aging are sieved to separate the alfalfa seeds and then soaked in distilled water for 48h to drain the water; 1.4mm, so choosing a suitable sieve can filter out the dry alfalfa seeds while removing the fine sand, leaving only the plump seeds.

[0041]...

Embodiment 3

[0051] A method for treating alfalfa seeds that improves stress resistance, comprising the following steps:

[0052] (1) Mix fine sand 12 according to the mass part ratio: alfalfa seed 1 and pack into a metal container to seal, wherein the particle diameter of fine sand is 1.2mm;

[0053] (2) Place the metal container filled with fine sand and alfalfa seeds in step (1) on a vibration aging platform and vibrate for 40 minutes, wherein the frequency of vibration aging is the metal container filled with fine sand and alfalfa seeds obtained by the equipment according to scanning. The natural frequency of the container is determined;

[0054](3) the fine sand and the alfalfa seed mixture obtained in step (2) after vibration aging are sieved to separate the alfalfa seeds and then soaked in distilled water for 40h to drain the water; 1.4mm, so choosing a suitable sieve can filter out the dry alfalfa seeds while removing the fine sand, leaving only the plump seeds.

[0055] (4) Soak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com