Self-cleaning culture pond and self-cleaning method

A culture pond and self-cleaning technology, applied in the field of self-cleaning aquaculture ponds and self-cleaning, can solve problems such as inconvenience of dirt cleaning, and achieve the effects of convenient dirt cleaning, good cleaning effect and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

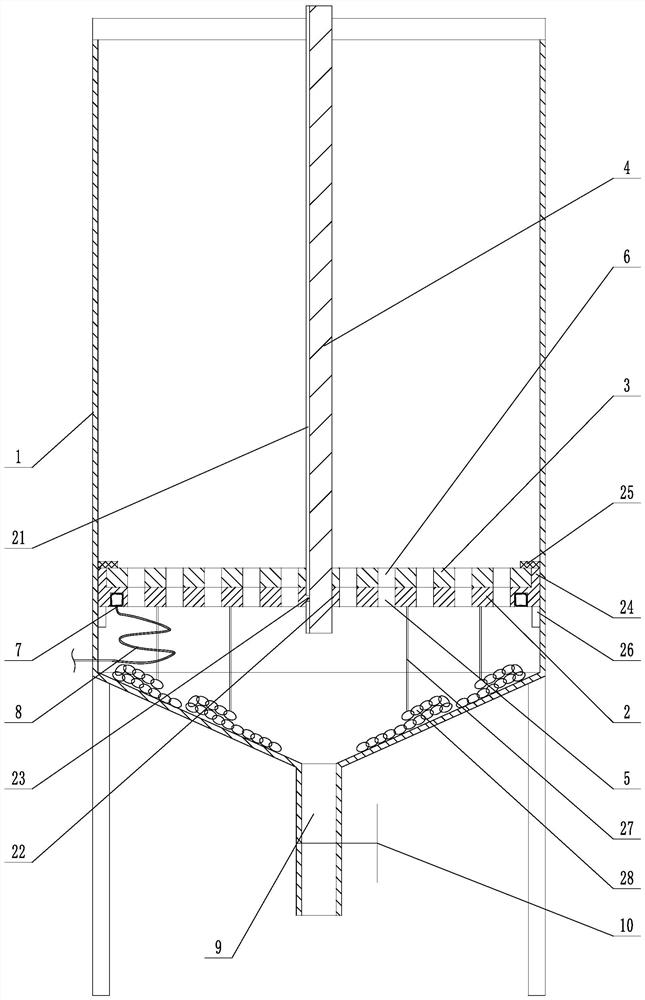

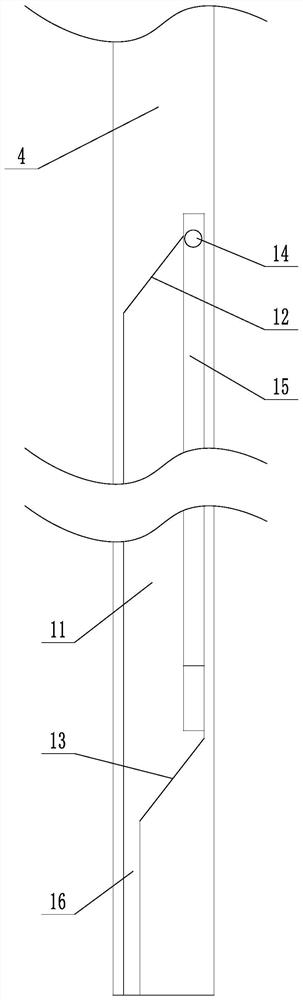

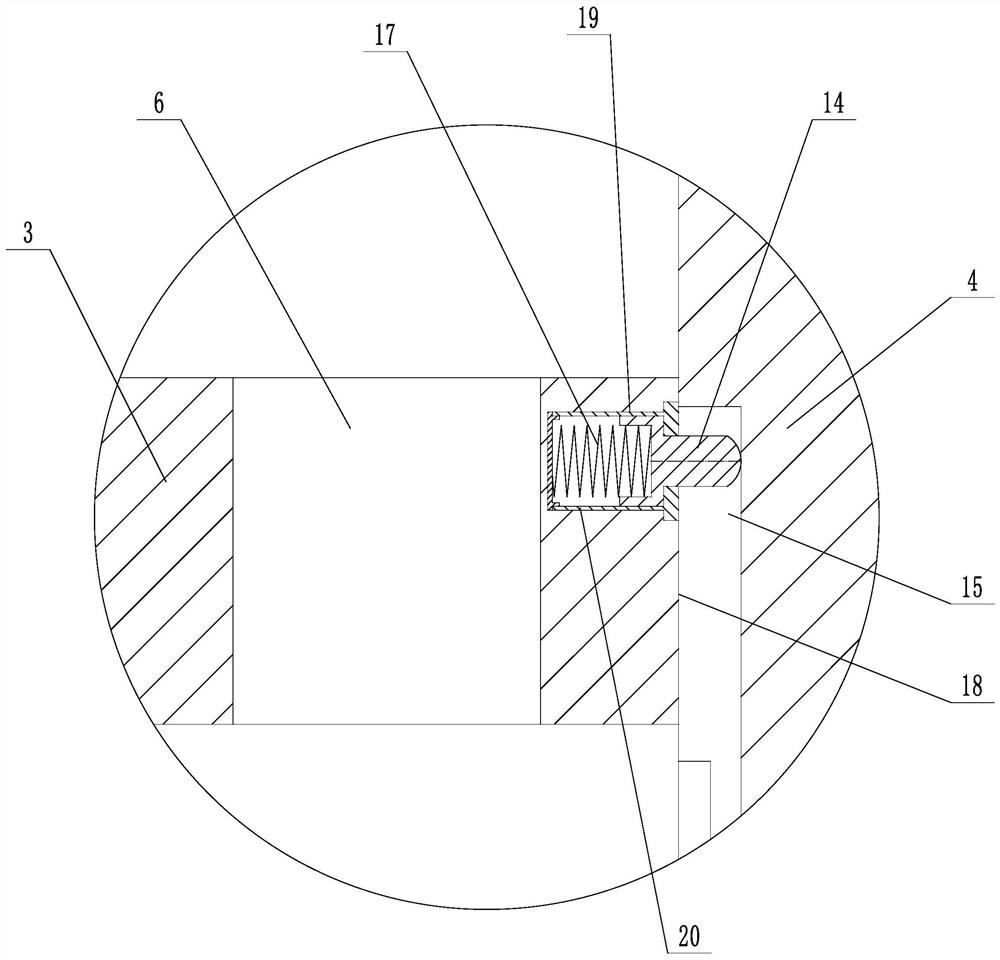

[0024] Embodiment: a kind of self-cleaning cultivation pool (see attached figure 1 to attach image 3 ), including a cylindrical culture pond body 1, a bottom plate 2, and a cover plate 3. A guide post 4 is installed in the culture pond body. The upper end of the guide post is connected to the upper end of the culture pond body through a bracket, and the lower end of the guide post is suspended. The base plate and the cover plate are all set on the guide post, the cover plate can be rotatably installed on the base plate, the base plate can be lifted and installed in the culture pond body near the lower position, the base plate is provided with several lower through holes 5, the cover plate and the lower through hole are aligned One is provided with a plurality of upper through holes 6, and the lower surface of the bottom plate is provided with an annular groove, and an air bag 7 is installed in the annular groove, and the air bag is connected to the air filling and discharging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com