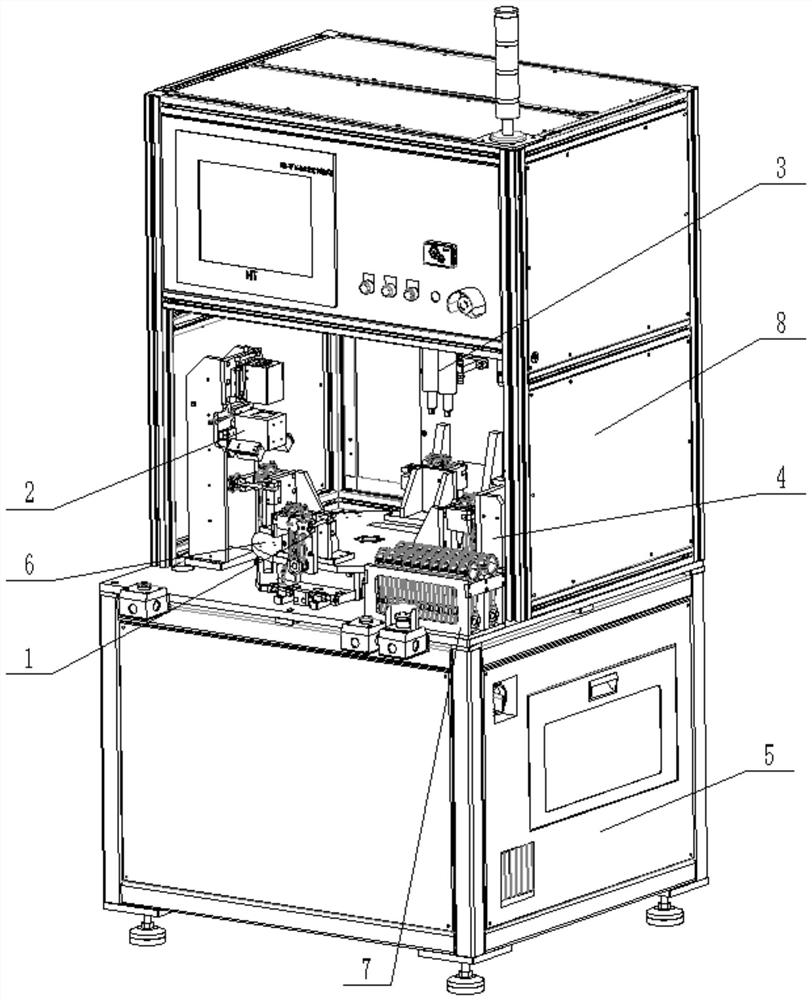

Automatic screw locking marking equipment

A technology for marking equipment and locking screws, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of inability to directly identify locking screws, locking screw limitations, etc., to prevent repeated screw locking operations and facilitate screw locking operations. , the effect of low human participation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

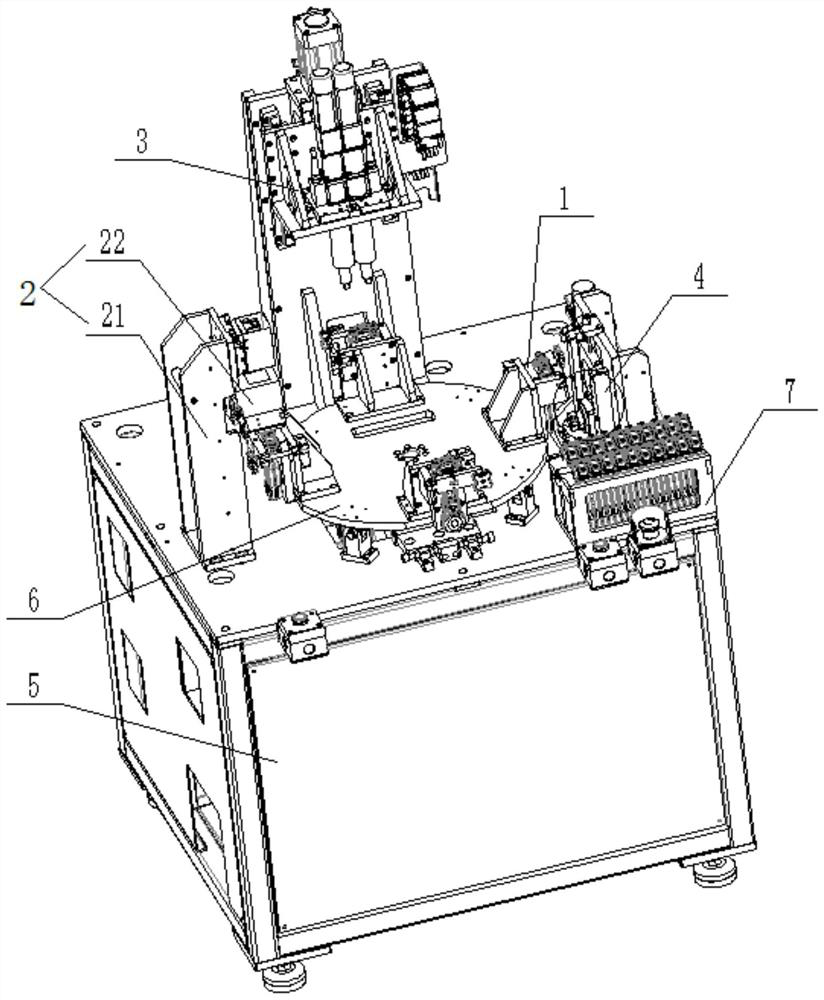

[0028] The present invention mainly includes a feeding installation structure 1, an identification mechanism 2, a screwing mechanism 3, and a marking mechanism 4, wherein the working principle of the screwing mechanism 3 is the prior art, but because the existing screwing mechanism 3 is simplex position, the present invention has made an improvement, using double stations to screw the screw, which is the innovation point of the present invention, and the combination of the above four to use the product to screw the product is also the innovation point of the present invention; the structure of the present invention will be done below Detailed elaboration.

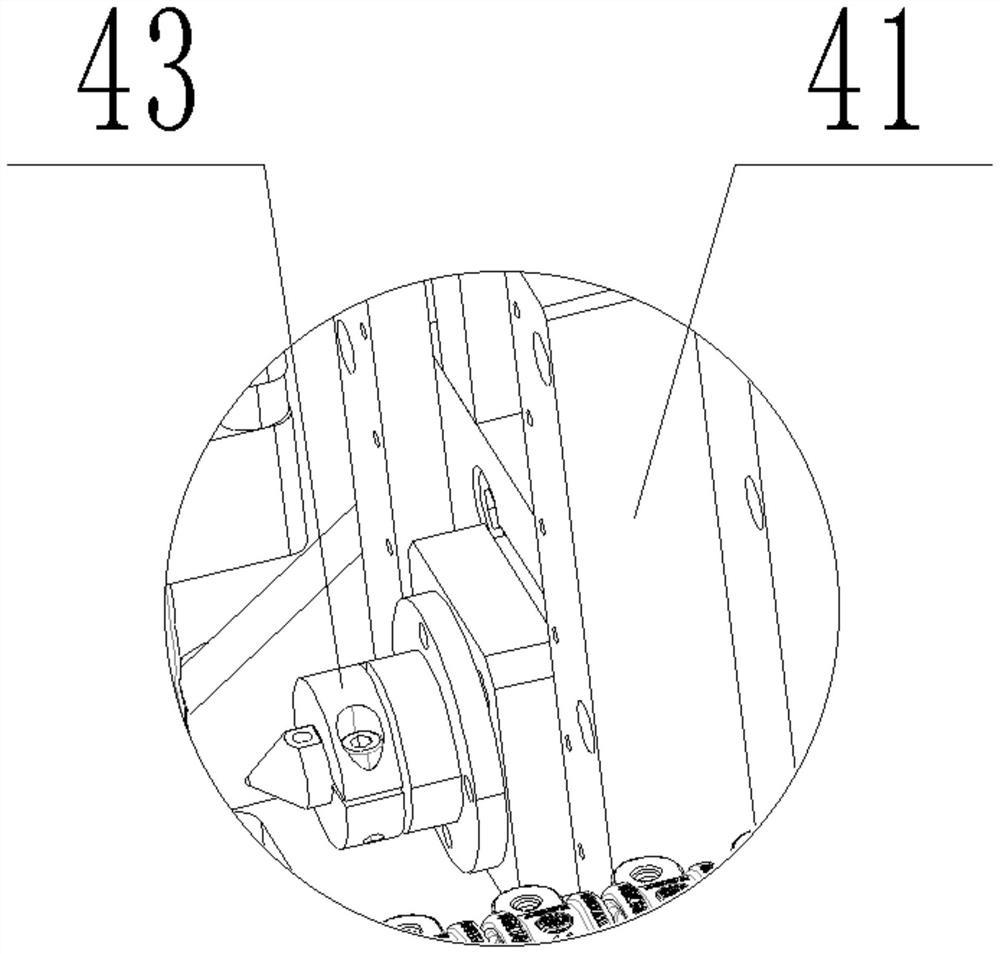

[0029] First is the loading installation structure 1, the loading installation structure 1 includes a base plate 11 that plays a supporting role, a support plate 12 arranged above the base plate 11, a fixed block 13 arranged on the support plate 12, and a support plate that leans against the support plate. 12, the backing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com