Transfer robot capable of achieving complete-cycle motion

A technology for handling robots and robots, applied in the field of handling robots, can solve problems such as objects falling off and objects being damaged, and achieve the effect of improving work efficiency and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

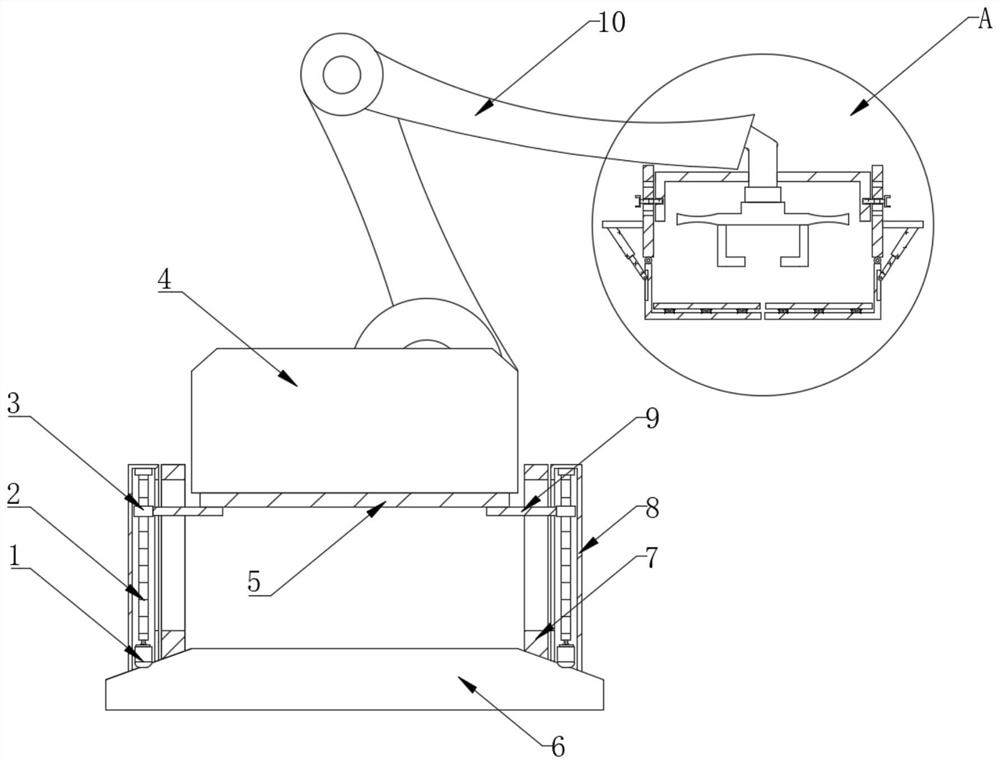

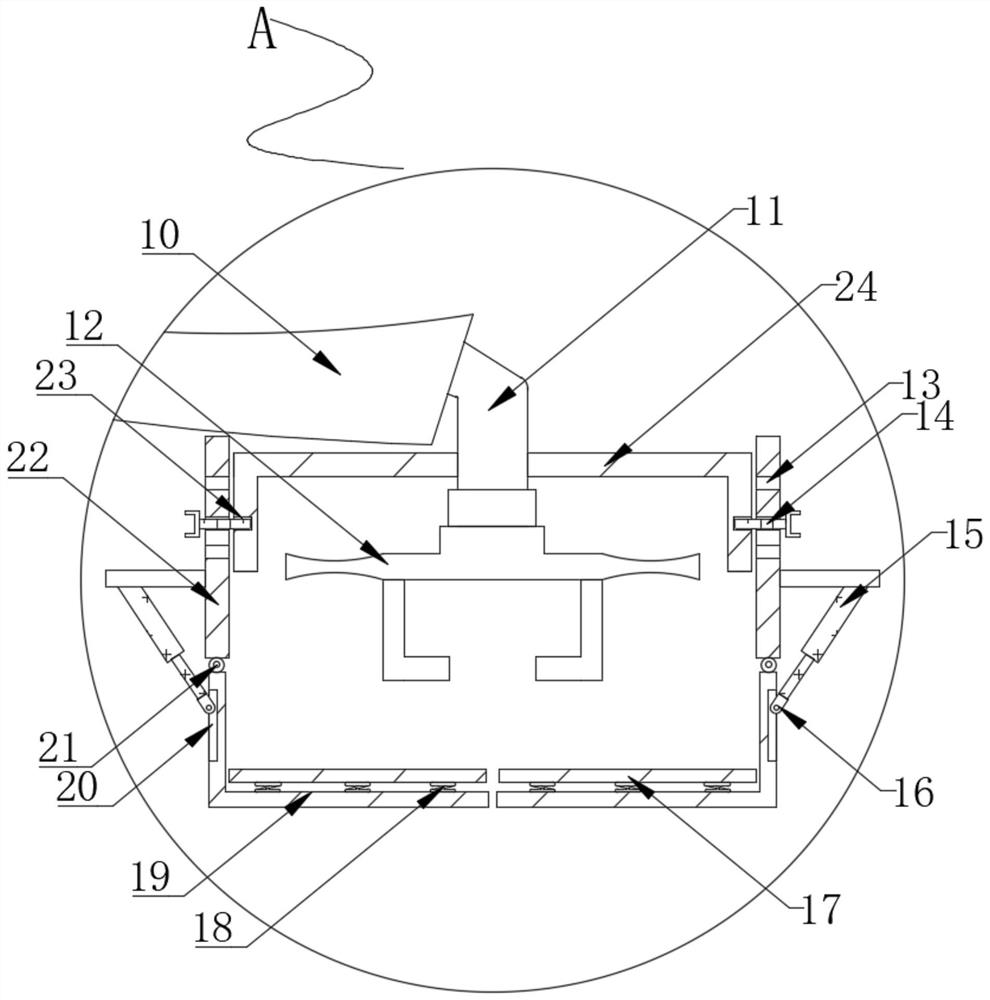

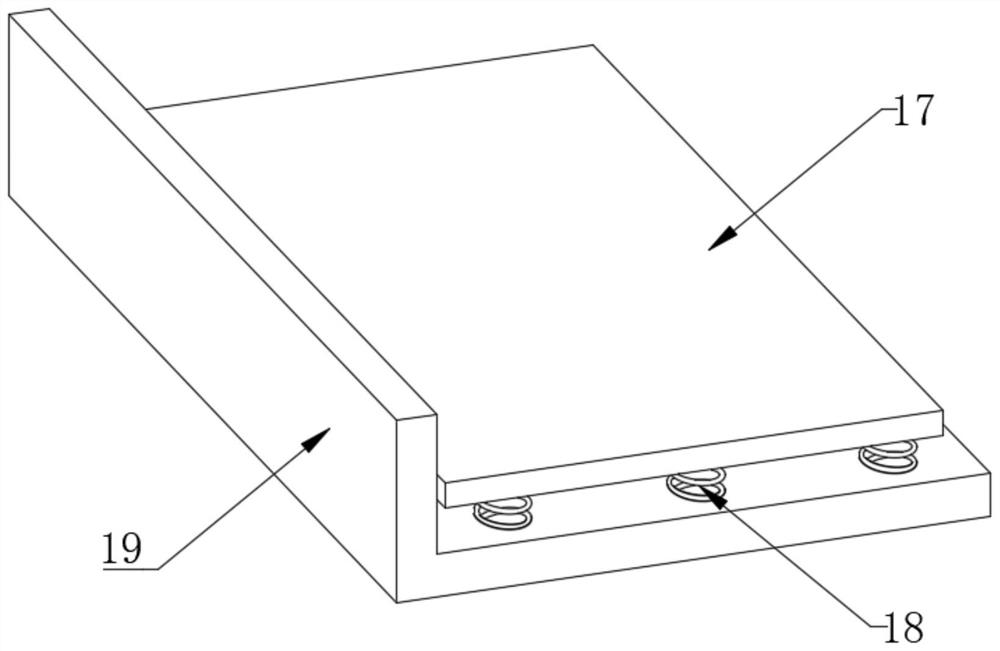

[0025] see Figure 1~3 , in an embodiment of the present invention, a handling robot with full circle motion includes a base 6, a robot body 4 is arranged on the top of the base 6, and a robot arm 10 is connected to the top of the robot body 4, and one end of the robot arm 10 is connected to a Grab hand 12, the bottom end of grab hand 12 is provided with grab hand support frame 11, and the outside of grab hand 12 is connected with two connecting plates 24, and one side of connecting plate 24 is connected with second supporting plate 22, the second One side of the second support plate 22 is equipped with an electric telescopic rod 15, the bottom end of the second support plate 22 is provided with a movable plate 19, the top of the movable plate 19 is equipped with a first hinge 21, and one side of the movable plate 19 is provided with a chute 20. The bottom end of the electric telescopic rod 15 is provided with a slider 16 .

[0026] Wherein, the sides of the two connecting pl...

Embodiment 2

[0034] refer to figure 1 , a handling robot with full circle movement. Compared with Embodiment 1, this embodiment also includes a first support plate 7 connected to both sides of the top of the base 6, and an installation box 8 connected to both sides of the top of the base 6. The top inside the box 8 is provided with a ball screw 2, the bottom inside the installation box 8 is installed with a motor 1, the outside of the ball screw 2 is sleeved with a ball nut 3, the outside of the ball nut 3 is connected with a connecting rod 9, and the robot body 4 The bottom end is connected with supporting plate 5.

[0035] Wherein, the connection between the ball screw 2 and the installation box 8 is provided with a roller, one end of the ball screw 2 is connected with the roller, and the other end of the ball screw 2 is connected with the output shaft of the motor 1 .

[0036] Wherein, one side of the connecting rod 9 is connected with the outer side of the ball nut 3, and the top end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com