Reverse landing conversion construction method for profile steel cantilever scaffold

A technology of cantilevered scaffolding and construction method, which is applied in the accessories of scaffolding, scaffolding supported by housing structure, housing structure support, etc., can solve the problem of exterior wall appearance quality, high precision sealing requirements, leakage and other problems affecting prefabricated finished products. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

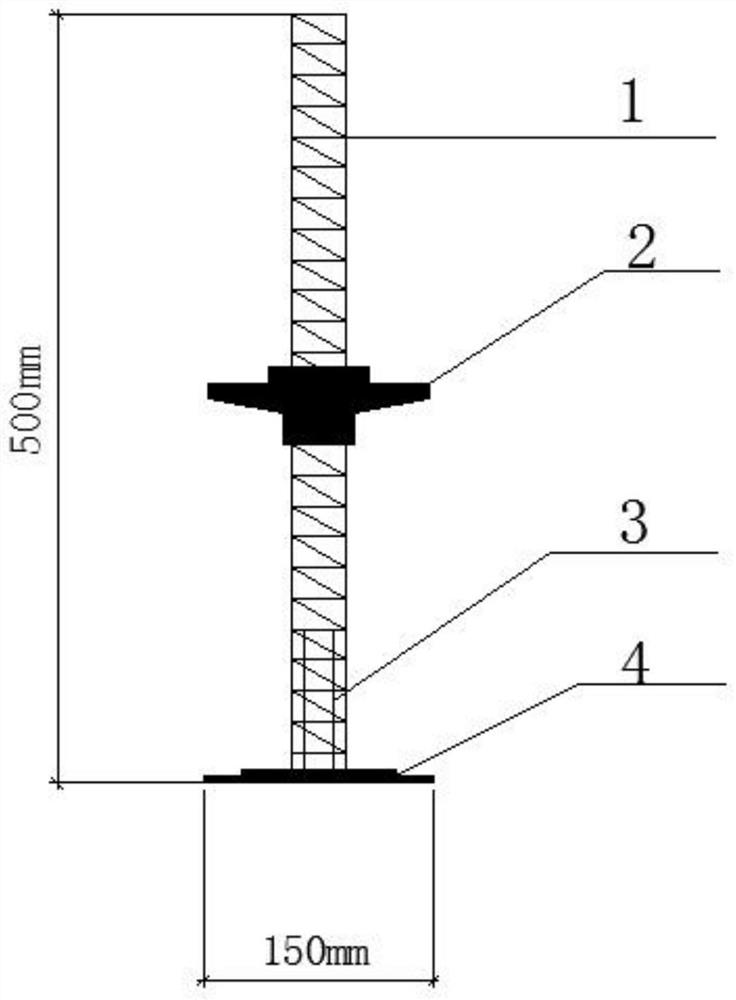

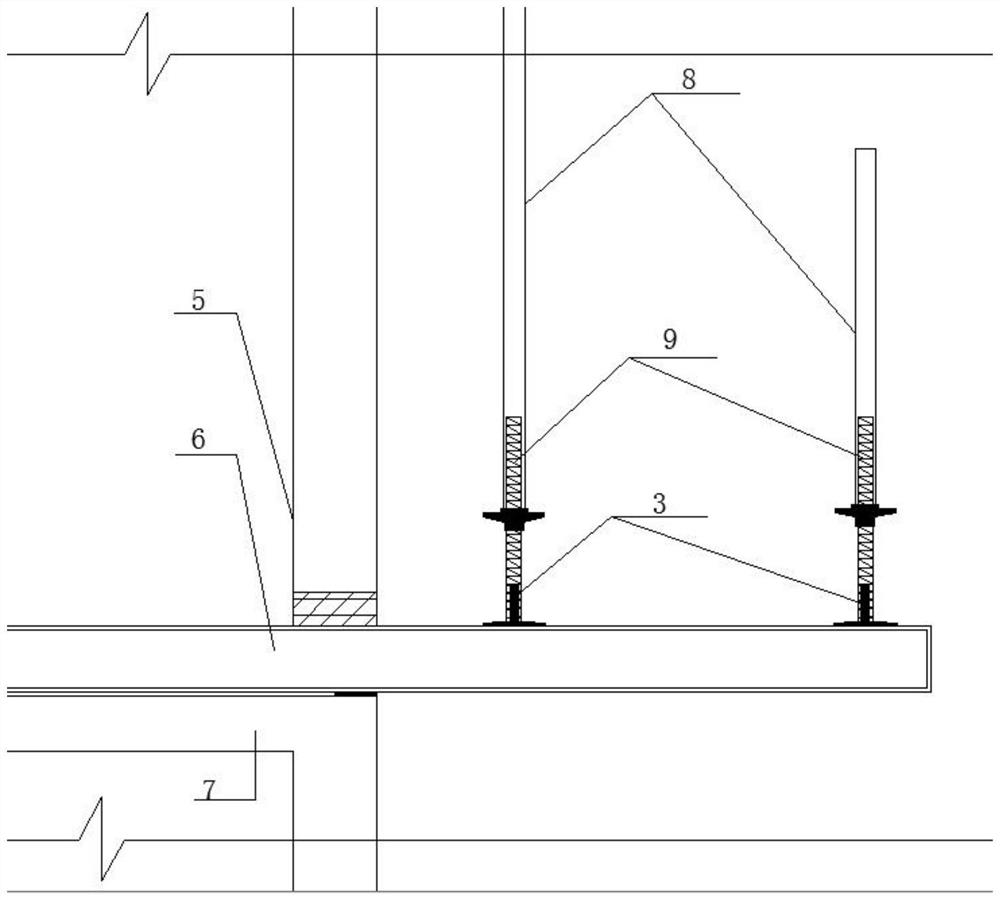

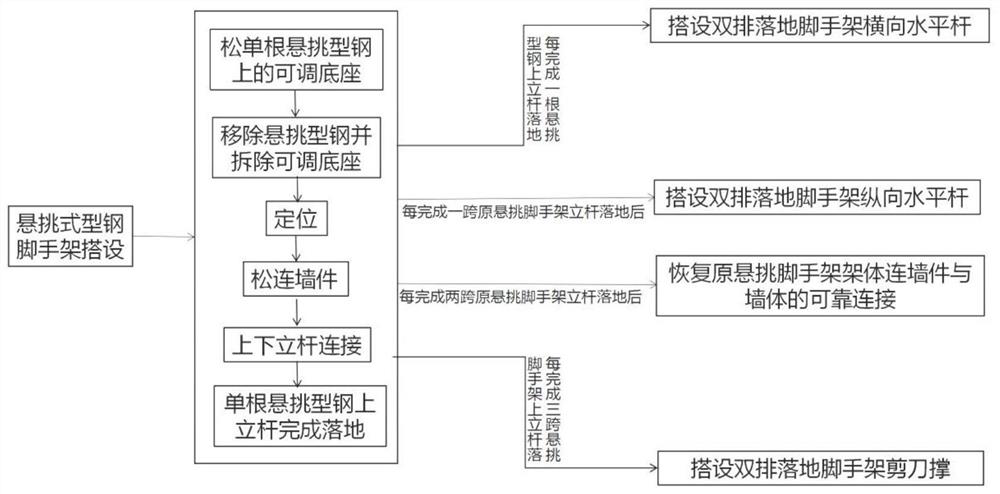

[0031] A construction method for reverse landing conversion of sectioned steel cantilevered scaffolding, step 1, erecting sectioned steel cantilevered scaffolding with a height of 1`2 floors and no more than 9m according to the project-specific scaffolding plan, wherein the section between the vertical pole of the sectioned steel cantilevered scaffold and the cantilevered section steel An adjustable base is set, that is, an adjustable base is installed on each cantilevered steel, and a vertical pole is connected on the adjustable base. The other components of the steel cantilevered scaffold body are still erected according to the traditional construction method and must comply with the relevant specifications of the scaffold.

[0032] Step 2, remove the cantilevered steel one by one and connect the poles on the cantilevered steel one by one. That is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com