Pulse current generation method for battery testing

A pulse current and battery testing technology, which is applied to the parts of electrical measuring instruments, the improvement of basic electrical components, and the measurement of electricity. state accuracy, precise amplitude control, and precise pulse time control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

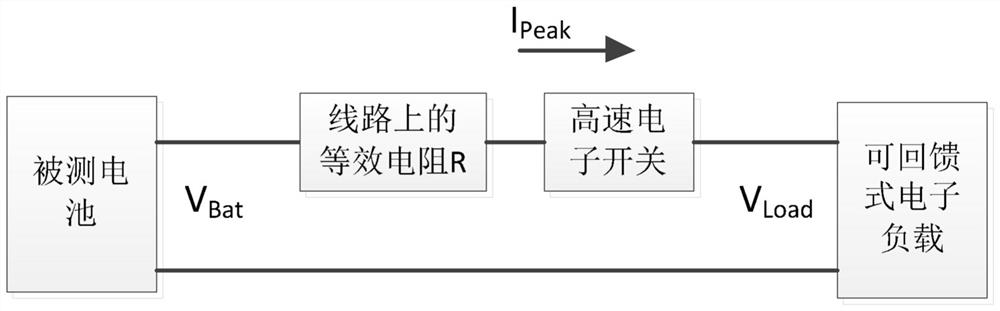

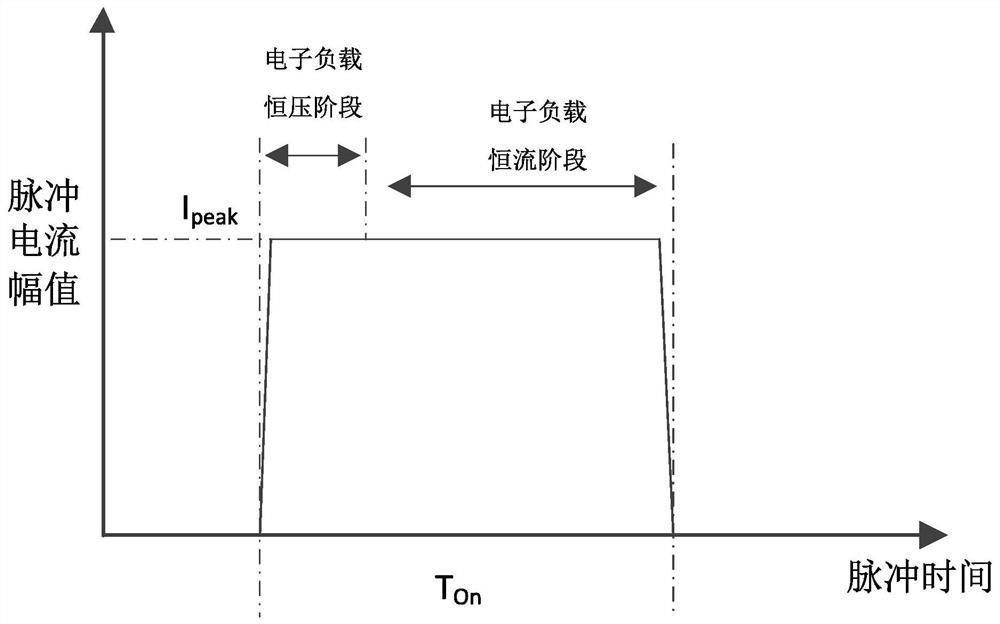

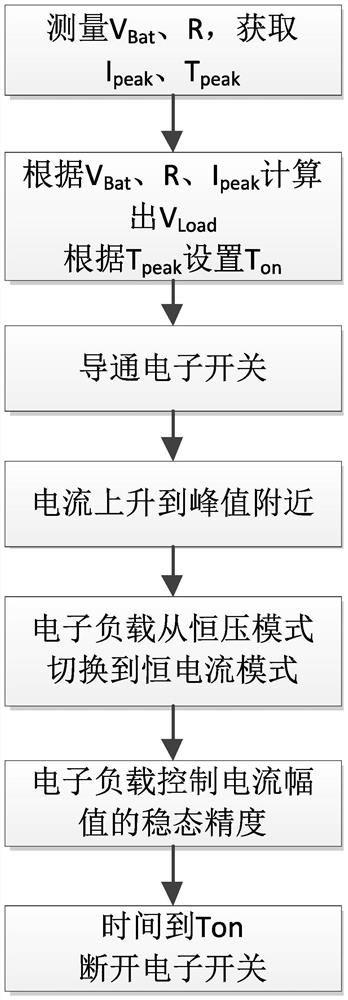

[0036] Such as Figure 1-4 As shown, a pulse current generation method for battery testing, the method specifically includes the following steps:

[0037] Step 1: Measure VBat, R, obtain Ipeak, Tpeak;

[0038] Step 2: Calculate Vload according to VBat, R, and Ipeak, and set Ton according to Tpeak;

[0039] Step 3: turn on the high-speed electronic switch;

[0040] Step 4: The current rises to near the peak value;

[0041] Step 5: The electronic load switches from constant voltage mode to constant current mode;

[0042] Step 6: The electronic load controls the steady-state accuracy of the current amplitude;

[0043] Step 7: Turn off the electronic switch when the time is up to Ton;

[0044] The measured battery voltage is VBat, the regenerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com