Installation structure of wide-angle lens

A technology of installation structure and wide-angle lens, which is applied in installation, optics, instruments, etc., can solve problems such as difficulty in ensuring stability, and achieve the effect of easy assembly, reduced outer diameter, and caliber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The features of the present invention and other relevant features are described in further detail below through the embodiments, so as to facilitate the understanding of those skilled in the art:

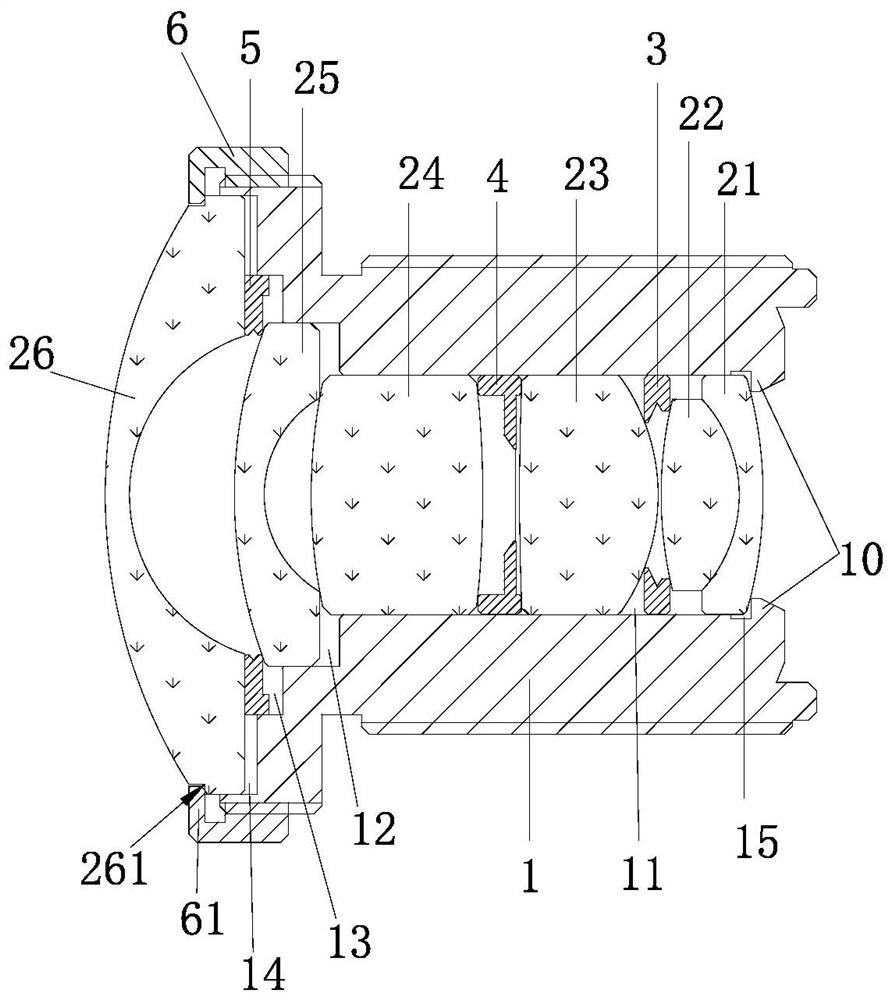

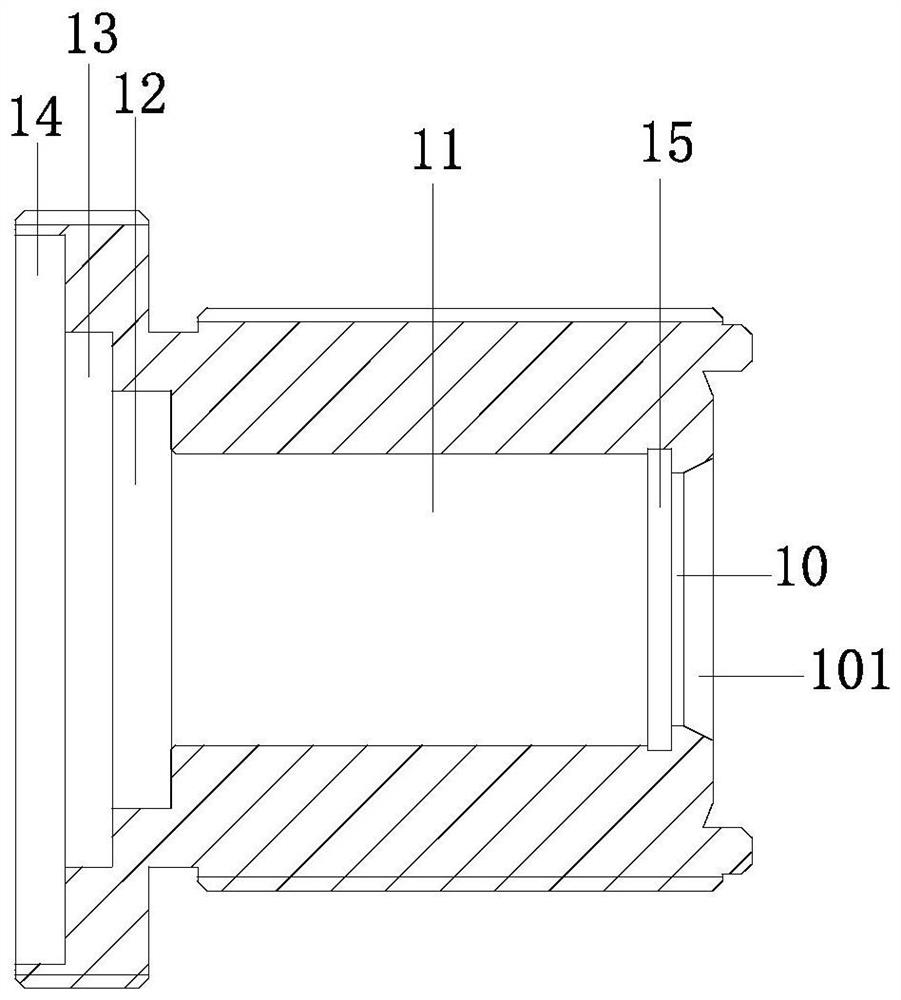

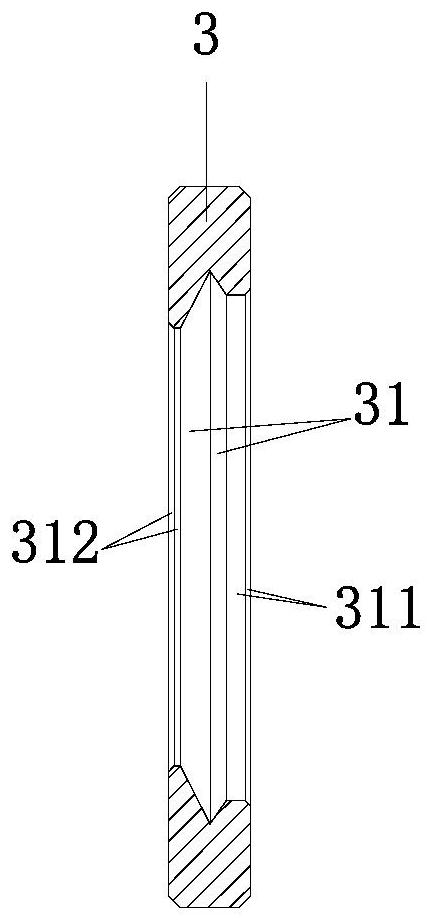

[0023] Such as Figure 1 to Figure 6 As shown, a wide-angle lens installation structure includes a lens barrel 1, and the lens barrel 1 is sequentially provided with an annular stop protrusion 10, a first circular channel 11, and a second circular channel from the image side to the object side. Channel 12, the third circular channel 13, the fourth circular channel 14, the inner diameter of the first circular channel 11, the inner diameter of the second circular channel 12, the inner diameter of the third circular channel 13, the fourth circular channel The inner diameter of the channel 14 is arranged from small to large, and the first meniscus lens 21, the second double-convex lens 22, the first spacer 3, and the third double-lens lens are installed in the lens barrel 1 in or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com