Tube bundle two-dimensional rapid drawing method and system based on full three-dimensional design and storage medium

A technology of 3D design and 2D drawing, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as inability to convert 3D design drawings into 2D drawings, random changes in 2D drawings, and inaccurate estimated dimensions. , to achieve the effect that the characteristic parameters are clearly visible, the strapping length is clearly visible, and the connection object is clear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

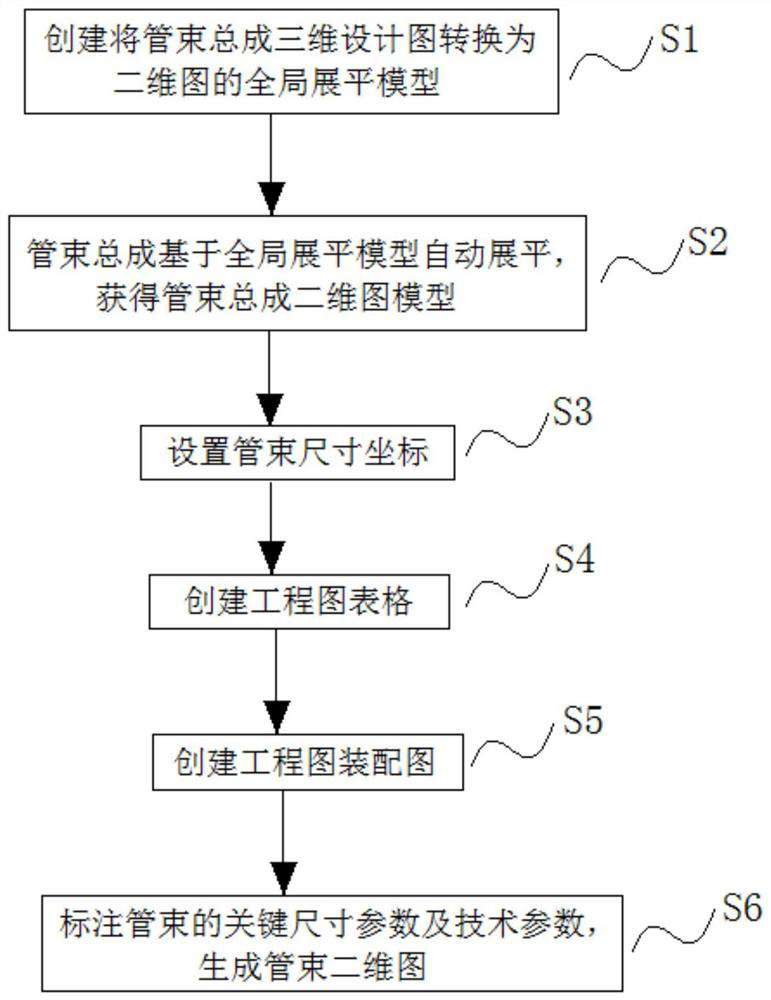

[0060] like figure 1 As shown, this embodiment discloses a method for quick two-dimensional drawing of tube bundles based on full three-dimensional design, and the method is specifically as follows:

[0061] S1: Create a global flattened model that converts the 3D design drawing of the tube bundle assembly into a 2D drawing;

[0062] In this step S1, the global flattened model is an auxiliary model created by the three-dimensional design model of the tube bundle assembly according to the requirements of the manufacturing process to realize the generation of a two-dimensional diagram, that is, a conversion model for converting the three-dimensional design diagram of the tube bundle assembly into a two-dimensional diagram;

[0063] In this step S1, the global flattened model is associated with the three-dimensional design model of the tube bundle assembly, and the creation process of the global flattened model includes:

[0064] Select the flattening starting point of the tube bu...

Embodiment 2

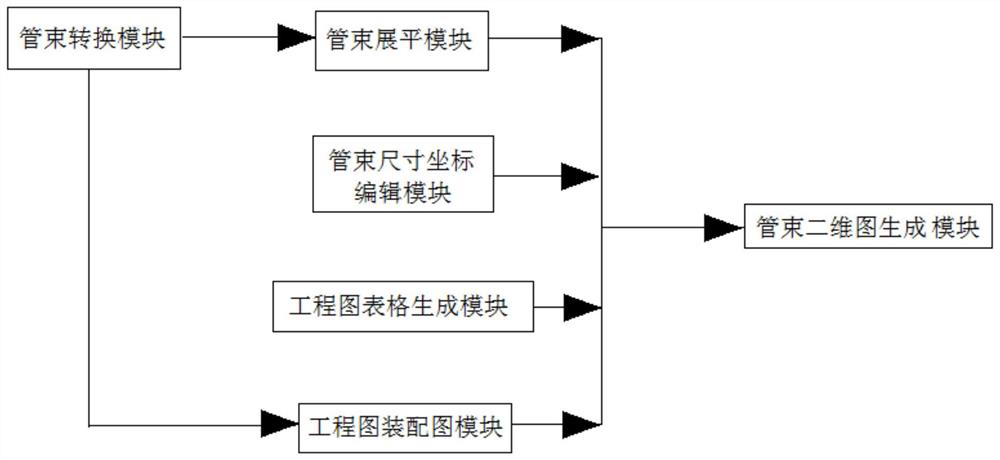

[0101] like figure 2 As shown, this embodiment discloses a two-dimensional fast drawing system for tube bundles based on full three-dimensional design, and the system includes:

[0102] A tube bundle conversion module, the tube bundle conversion module has a built-in global flattening model, which is used to convert the three-dimensional design drawing of the tube bundle assembly into a two-dimensional drawing;

[0103] Tube bundle flattening module, including tube bundle flattening unit and tube bundle flattening adjustment unit;

[0104] The tube bundle flattening unit is used to transfer the global flattening model in the tube bundle conversion module, and after flattening the tube bundle, associate and assemble the connection elements;

[0105] The tube bundle flattening adjustment unit is used to adjust the model branch so that the model branch is perpendicular to the direction of the main tube bundle, adjust all the tube bundles and joints of the global flattened model...

Embodiment 3

[0116] The third embodiment discloses a computer-readable storage medium, on which a computer program is stored, and the computer program can implement the two-dimensional fast drawing method for tube bundles described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com