Improved furniture drawer assembly structure

A technology for assembling structures and drawers, which is applied to drawers, furniture parts, household appliances, etc., can solve the problems of drawers that cannot be quickly disassembled and can only be used for wood drawers, etc. Improve the appearance and the effect of improving the user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

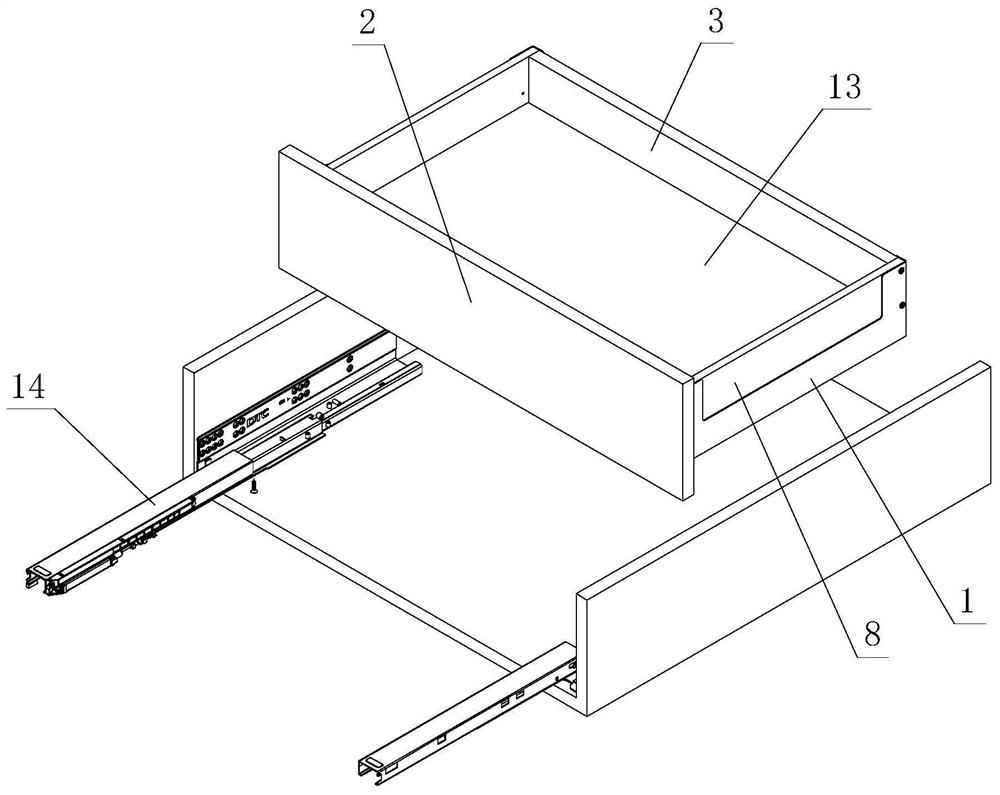

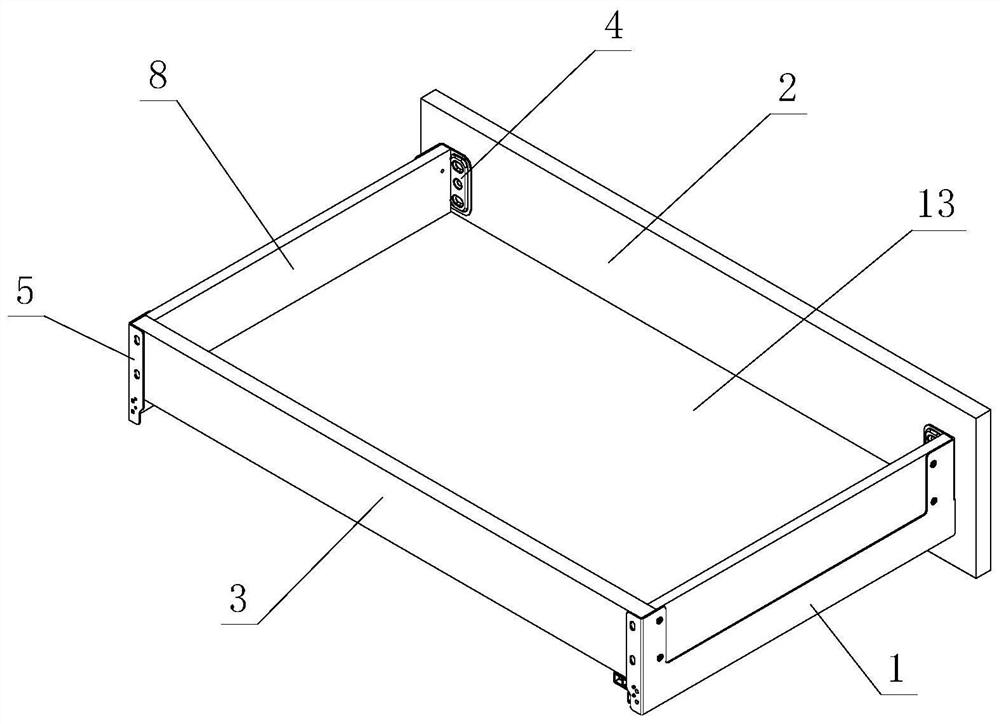

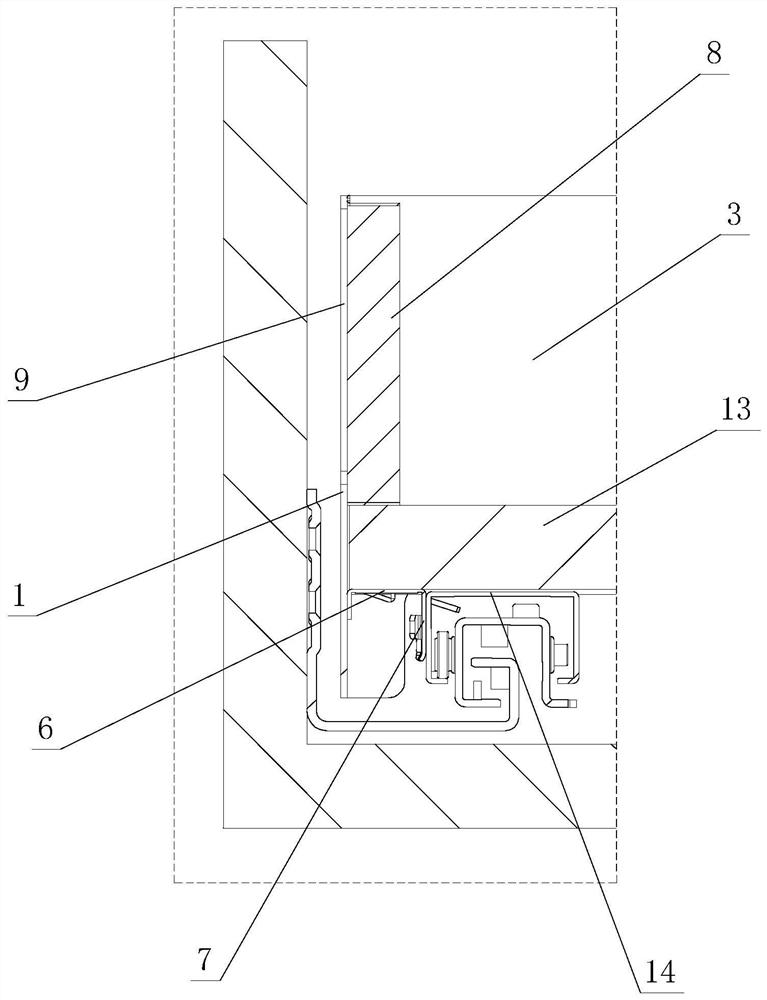

[0043] see Figure 1-Figure 15 , the improved furniture drawer assembly structure includes a side panel 1, a front panel 2 and a rear panel 3, the front and rear ends of the side panel 1 are respectively integrally bent with a front bending part 4 and a rear bending part 5, and the lower part is integrally formed or divided The body is provided with a supporting part 6, and the supporting part 6 is integrally formed downwards or separately provided with a relying part 7. The lower part of the side plate 1 in this embodiment is provided with a supporting part 6, and the supporting part 6 is integrally formed downward with a relying part 7 .

[0044] The side plate 1 is also provided with an assembly plate 8 and a notch 9, the assembly plate 8 is located inside the notch 9 and is fixedly arranged on the side plate 1; the front plate 2 and the rear plate 3 are respectively fixed on the side plate 1.

[0045] A notch 9 is provided on the side plate 1, and then the assembly plate...

no. 2 example

[0064] see Figure 16-Figure 22 , the improved furniture drawer assembly structure differs from the first embodiment in that: the front plate 2 is located behind the front bending part 4, and the front plate 2 is fixed by clamping, or fixing parts, or pasting, or magnetic parts. On the bent portion 4 or the front side wall 10 .

[0065] Specifically, the front plate 2 of this embodiment.

[0066] Such as Figure 16-Figure 18 As shown, the front end of the assembly plate 8 is fixedly arranged on the front side wall 10 through the fixing member, and the rear end is fixedly arranged on the rear side wall 11 through the fixing member.

[0067] The front end of the assembly plate 8 relies on the front bending part 4, and the rear end relies on the rear bending part 5; , and fixedly arranged on the rear bending part 5 through a fixing piece; the front plate 2 is located behind the front bending part 4, and its end part relies on the inner side of the front end of the assembly pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com