V-shaped filter tank and backwashing method thereof

A backwashing and filter technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of cleaning, waste of water resources, unfavorable filters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

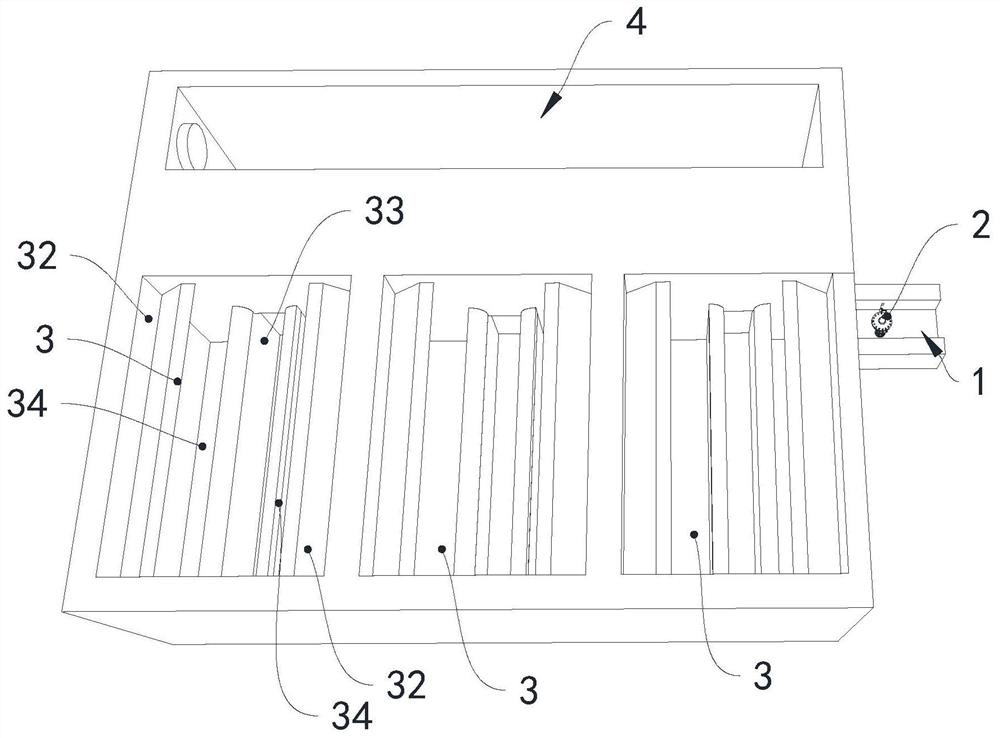

[0021] see image 3 and Figure 4 , the V-shaped filter includes a main water inlet channel 4, a sewage collection channel 1, a turbidity meter 2, a drain valve and a plurality of filter tank bodies 3, and a plurality of filter tank bodies 3 are arranged side by side, and each filter tank body 3 is connected to the inlet The main water channel 4 is connected, and the extension direction of the main water channel 4 is parallel to the arrangement direction of the filter body 3. The filter body 3 includes a long-handled filter head, a filter material, and two V-shaped grooves 32 arranged in parallel, a drain Canal 33 and two filter tank parts 34, drainage channel 33 is positioned between two filter tank parts 34, and filter tank part 34 is positioned between drainage channel 33 and V-shaped groove 32, and the bottom of filter tank part 34 is arranged with multiple Long handle filter head, long handle filter head is used for distributing backwash water and gas, filter material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com