A hydraulically driven fracturing skid

A hydraulic transmission and fracturing technology, which is applied in wellbore/well parts, transportation and packaging, mixers with rotating stirring devices, etc., can solve the problems of low processing efficiency, pretreatment and low mixing efficiency, and achieve improved Effectiveness and efficiency, increased productivity, flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

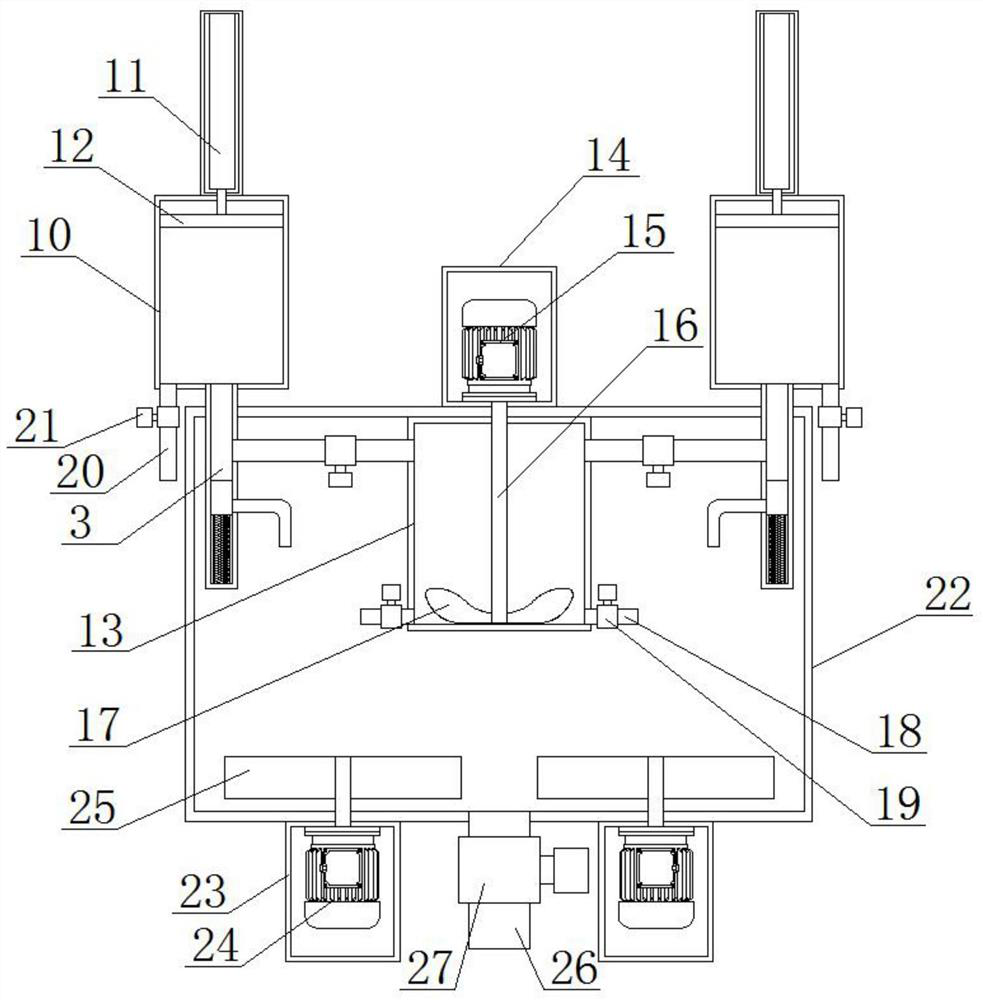

[0021] As a preferred embodiment of the present invention, the pretreatment device 2 is fixedly installed on the top of the fracturing skid body 1 .

[0022] As a preferred embodiment of the present invention, the number of the second motor housing 23 and the stirring impeller 25 is two.

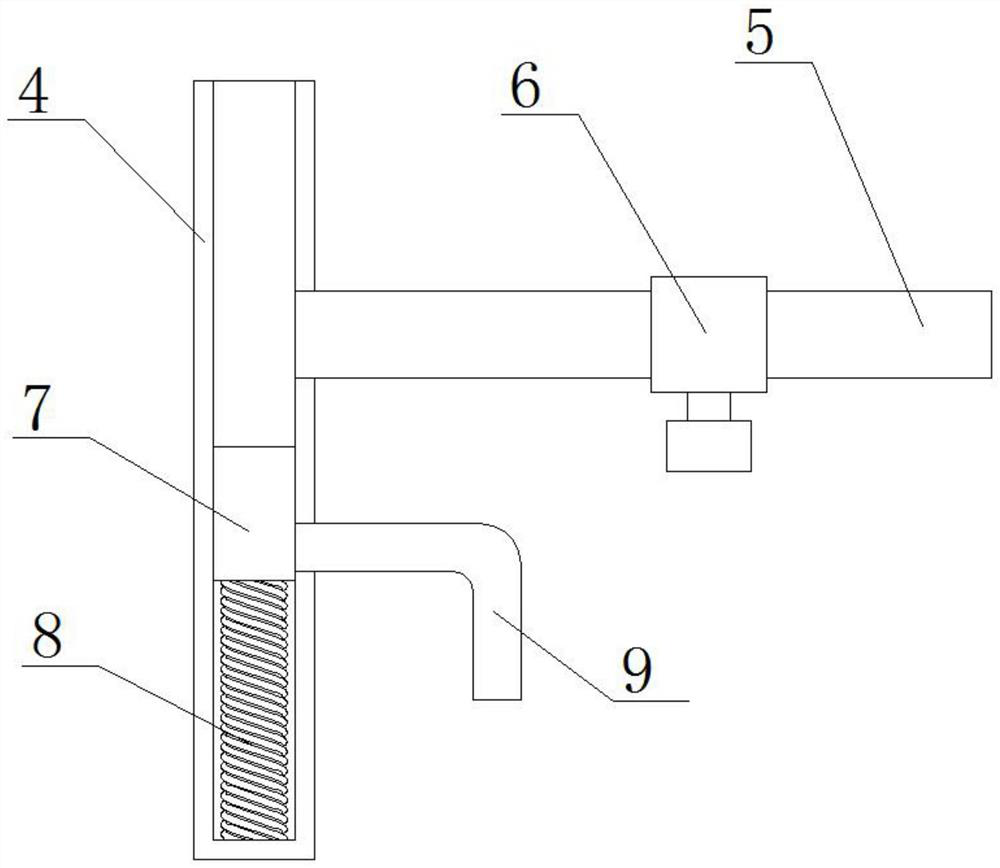

[0023] As a preferred embodiment of the present invention, one side of the direct-flow pipe 4 is fixedly connected with a direct-flow branch pipe 9 .

[0024] As a preferred embodiment of the present invention, a feed pipe 20 is fixedly connected to the bottom of one side of the raw material tank 10, and an electric valve 3 21 is installed on the feed pipe 20.

[0025] As a preferred embodiment of the present invention, a discharge pipe 26 is fixedly connected to the center of the bottom of the outer treatment tank 22, and an electric valve 27 is installed on the discharge pipe 26.

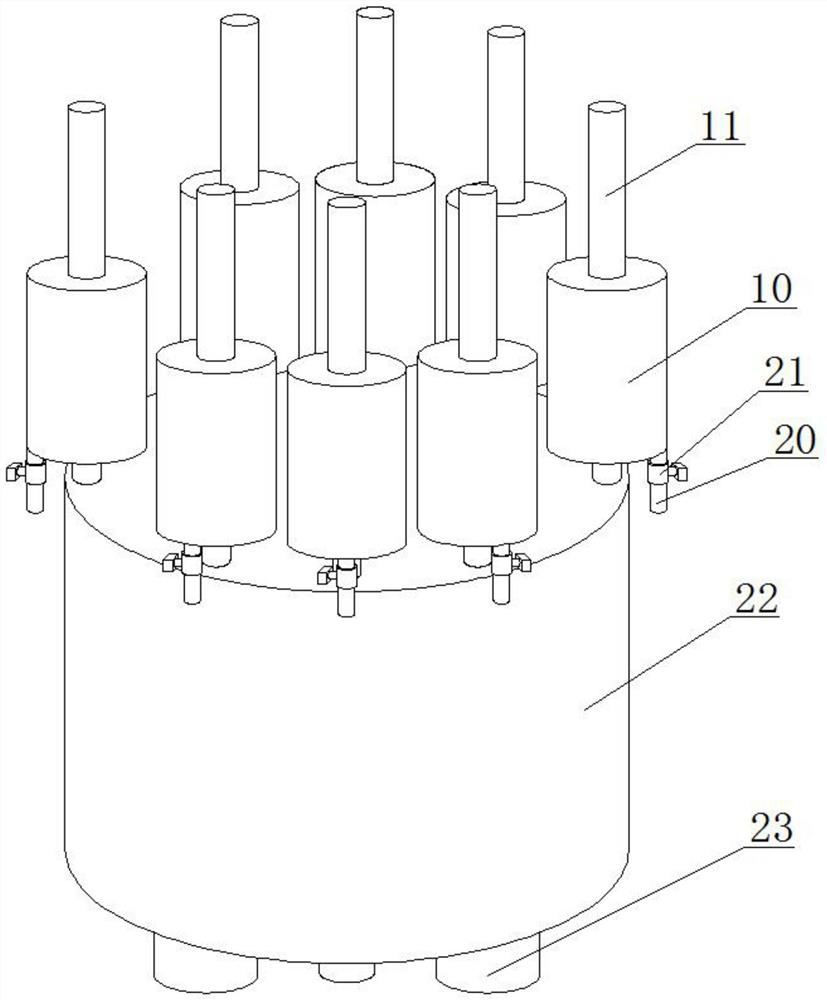

[0026] As a preferred embodiment of the present invention, several raw material tanks 10 are installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com