Dispensing disc achieving environment-friendly glue discharging

A ring-shaped dispensing and dispensing technology, applied in the field of dispensing machines, can solve the problems of too fast movement of the dispensing head, long dispensing time, and insufficient efficiency, and achieve good vertical deformation resistance, increased dispensing speed, and prevent deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

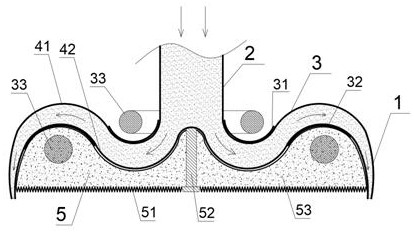

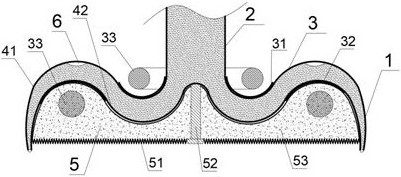

[0038] see Figures 1 to 3 And 5, a dispensing tray for annular glue discharge, including an annular glue needle 1 and a glue cartridge 2; the glue cartridge 2 is arranged in the middle of the glue dispensing tray, and passes through an annular glue channel 3 as a glue needle under external pressure 1 to supply glue, so that the glue liquid is extruded from the bottom of the glue needle 1; the vertical section of the glue channel 3 is a lying S-shaped curved channel.

[0039]Use the glue channel design of the S-shaped curved channel with the vertical section to reduce or avoid the occurrence of glue dripping. The principle is that when the glue dispensing is completed and the glue is stopped, the glue in the glue needle 1 will move down under gravity. A small distance, the distance can make the glue partially protrude from the glue outlet of the glue needle 1, but not enough to make it big and drip; The inner bend of the rubber needle is kept full of glue, and the filled glue...

Embodiment 2

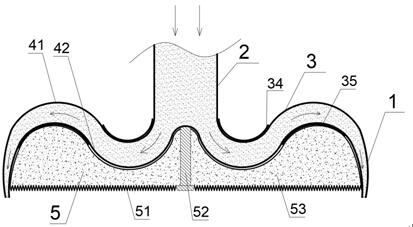

[0050] see Figure 4 and 5 , a ring-shaped dispensing disc for dispensing glue, including an annular glue needle 1 and a rubber cylinder 2; Glue, so that the glue liquid is extruded from the bottom of the glue needle 1; the vertical section of the glue channel 3 is a flat S-shaped curved channel.

[0051] Further, the glue needle 1 and the glue channel 3 are surrounded by the upper elastic sheet 41 and the lower elastic sheet 42; the upper elastic sheet 41 and the lower elastic sheet 42 are connected by a plurality of pieces evenly distributed around the center of the dispensing disc The sheet 43 is fixedly connected.

[0052] Further, the thickness of the upper elastic sheet 41 and the lower elastic sheet 42 and / or the connecting sheet 41 gradually decreases from the center of the dispensing tray outward.

[0053] Further, a serrated elastic disc 51 is arranged under the lower elastic sheet 42 and is sealed and fixedly connected with the inner and outer walls of the rubber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com