On-line Monitoring System of Blast Furnace Material Surface Shape

A monitoring system, blast furnace material level technology, applied in inspection devices and other directions, can solve the problems of complex laser cooling equipment and high cooling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

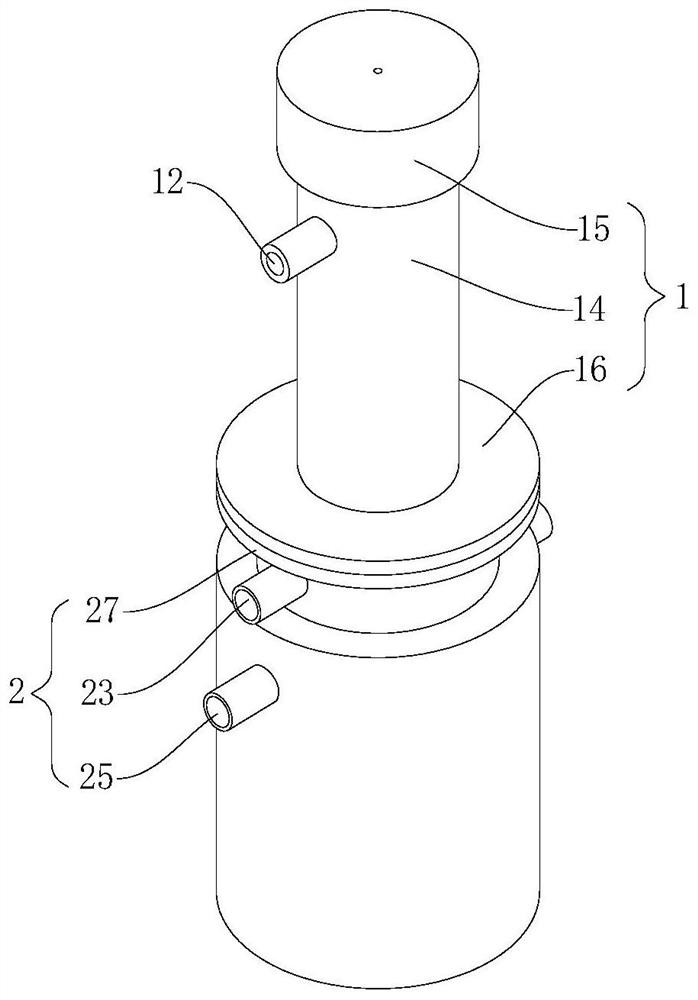

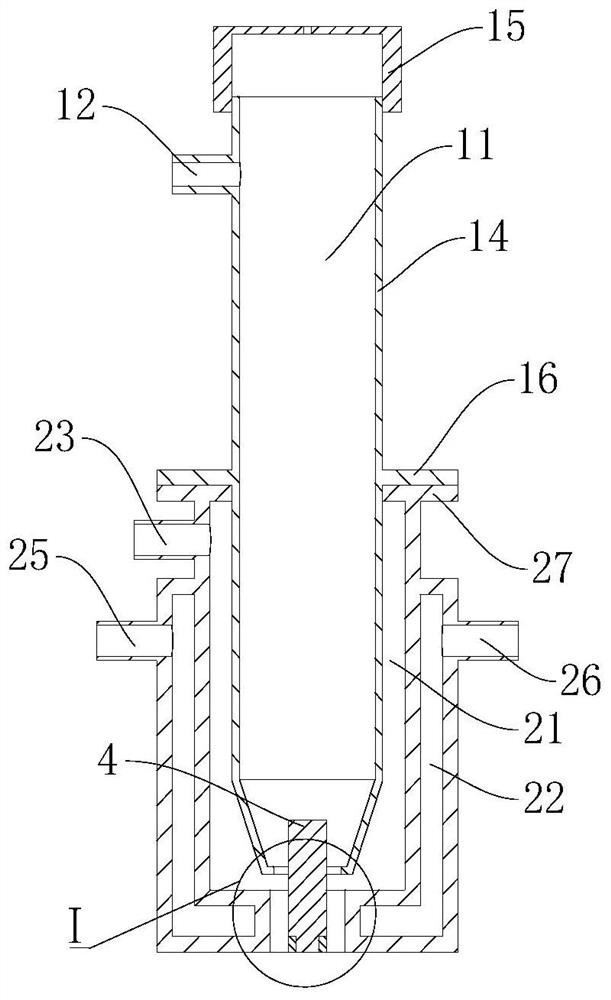

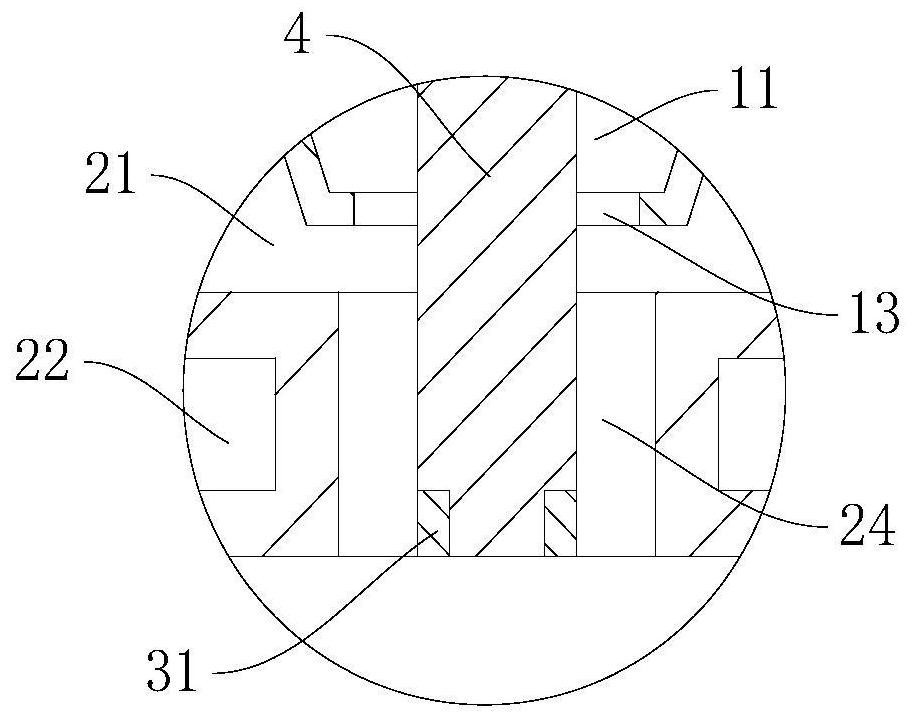

[0036] like Figure 1 ~ Figure 4 As shown, this embodiment proposes an online monitoring system for the shape of the blast furnace charge surface, including: a super-infrared laser scanning system, a digital camera system, a computer system, and a laser cooling system. It is characterized in that the laser cooling system includes:

[0037] The connecting body 1 has a first air chamber 11, a first air inlet 12 and a first air outlet 13, the first air inlet 12 and the first air outlet 13 communicate with the first air chamber 11 and form a first cooling air road;

[0038] The installation body 2 is connected with the connecting body 1. The installation body 2 has a second air chamber 21, a water chamber 22, a second air inlet 23, a second air outlet 24, a water inlet 25 and a water outlet 26, and the second air inlet 23 and the second air outlet 24 are in communication with the second air chamber 21 and form a second cooling air duct, the water inlet 25 and the water outlet 26 ...

Embodiment 2

[0059] like Figure 5 ~ Figure 7 As shown, the present embodiment also proposes the nozzle 5 and the absorbent cotton 6, the mounting body 2 is also provided with a water permeable hole 28, the water permeable hole 28 communicates with the second air chamber 21 and the water chamber 22, and the nozzle 5 is located at the water inlet 25 , the water permeable hole 28 is set opposite to the water outlet hole of the nozzle 5, and the absorbent cotton 6 is located in the second air chamber 21.

[0060] In this embodiment, a nozzle 5 is provided at the water inlet 25, a water-absorbent cotton 6 is provided in the second air chamber 21, and a water-permeable hole 28 is opened in the installation body 2, and the water-permeable hole 28 communicates with the second air chamber 21 and The water holding chamber 22, the water in the cooling water channel is sprayed into the water holding chamber 22 from the nozzle 5, and the water permeable hole 28 is arranged relative to the nozzle 5, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com