An Improved Method for Reducing NOx Formation of Top Combustion Hot Blast Stove

A hot blast stove and top-firing technology, applied in the combustion field, can solve the problem of high NOx emissions, achieve low NOx generation, increase service life, and reduce stress corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The improved method for reducing the amount of NOx produced by top-combustion hot blast stoves mainly includes the following steps:

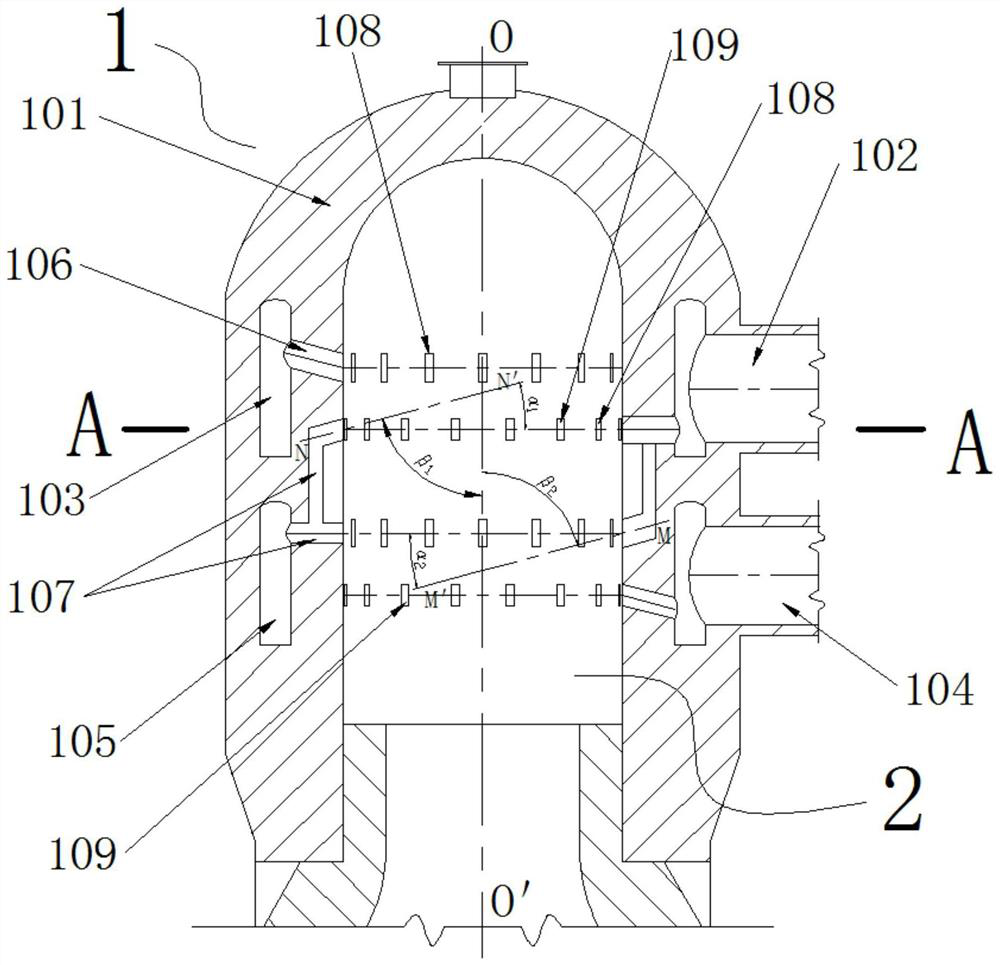

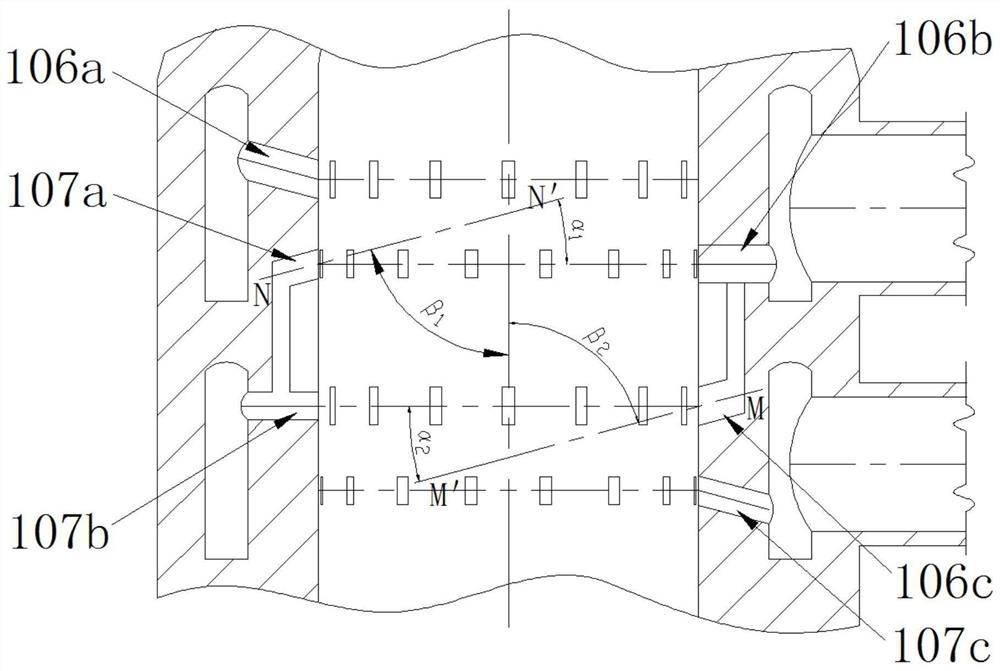

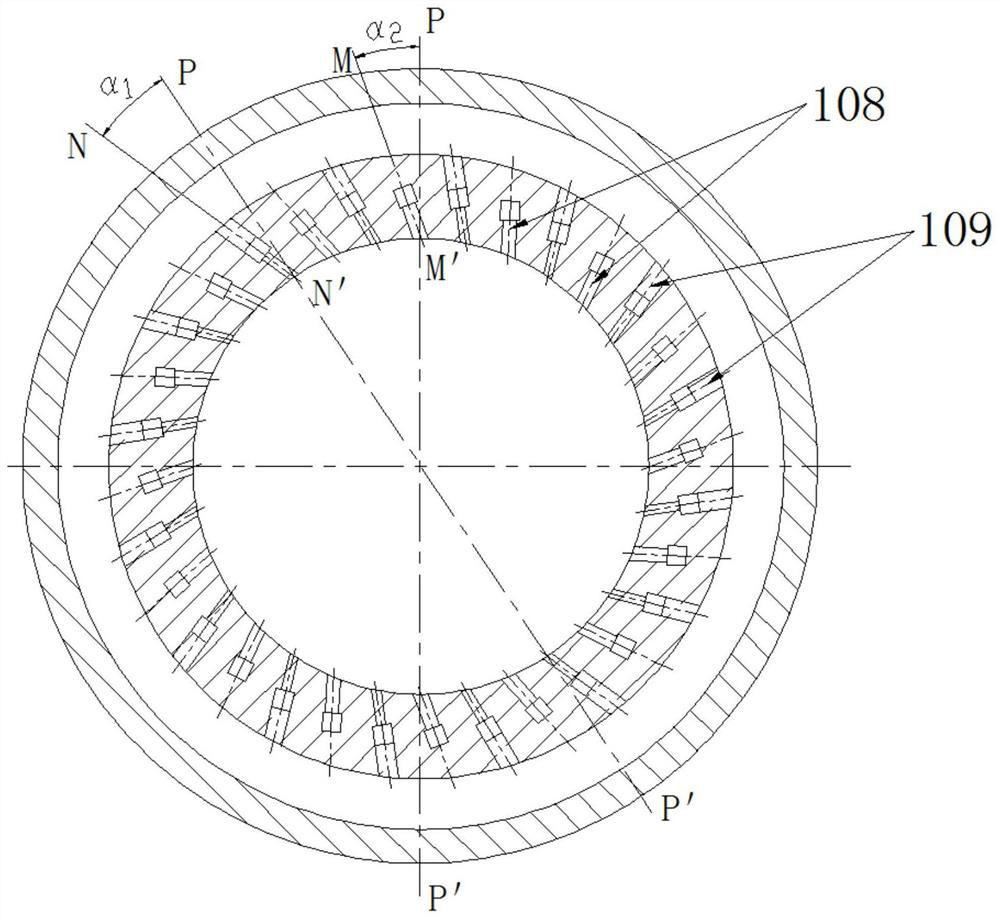

[0033] (1) Optimize the structure of the ceramic burner in the top-fired hot blast stove: such as Figure 1 to Figure 3 As shown, along the axis OO' direction of the burner, the gas distribution channel 106 passing through the ceramic lining 101 forms a multi-layer gas nozzle 108 on the inner wall surface of the ceramic lining 101, and passes through the air distribution channel 107 of the ceramic lining 101 Form multi-layer air nozzles 109 on the inner wall surface of the ceramic lining 101, part of the air nozzles 109 and gas nozzles 108 are arranged on the same layer to form an empty coal mixed layer; change the size of the cross-sectional area of the gas distribution channel 106 and the gas nozzles 108 of each layer Quantity, so that the gas flow of each layer is different; change the cross-sectional area size of the air distributio...

Embodiment 2

[0050] 1) First determine the number of gas nozzles according to the amount of gas. Assume that the total number of gas nozzles is 36, and there are three layers of gas nozzles from top to bottom. The number of gas nozzles on the first layer is 18, and the number of gas nozzles on the second layer is 9. , the number of gas nozzles on the third floor is 9. According to the numerical simulation, the total gas volume sprayed by the gas nozzles on each layer accounts for about 60%, 30%, and 10% respectively, and the opening sizes of the gas nozzles on the three layers are the same.

[0051] 2) Then determine the number of air nozzles according to the amount of air. The chemical equivalent ratio of air gas is about 0.63, and the total number of air nozzles is 24. There are also three layers of air nozzles from bottom to top, of which the number of air nozzles on the bottom layer is There are 12 air nozzles in the middle layer, 6 air nozzles in the middle layer, and 6 air nozzles in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com