LED line lamp

A technology of LED linear lamps and lamp holders, which is applied in lighting and heating equipment, semiconductor devices of light-emitting elements, lighting devices, etc., can solve the problems of difficult replacement, laborious plugging, damage to ceilings or walls, etc., and achieves simple structure, The effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

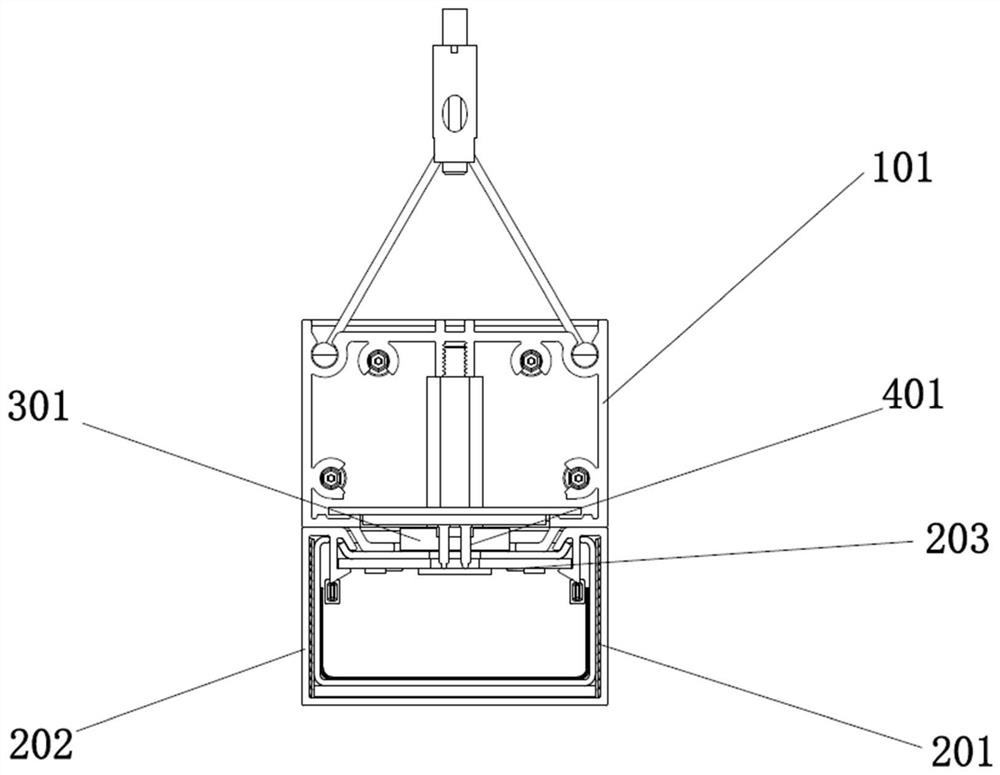

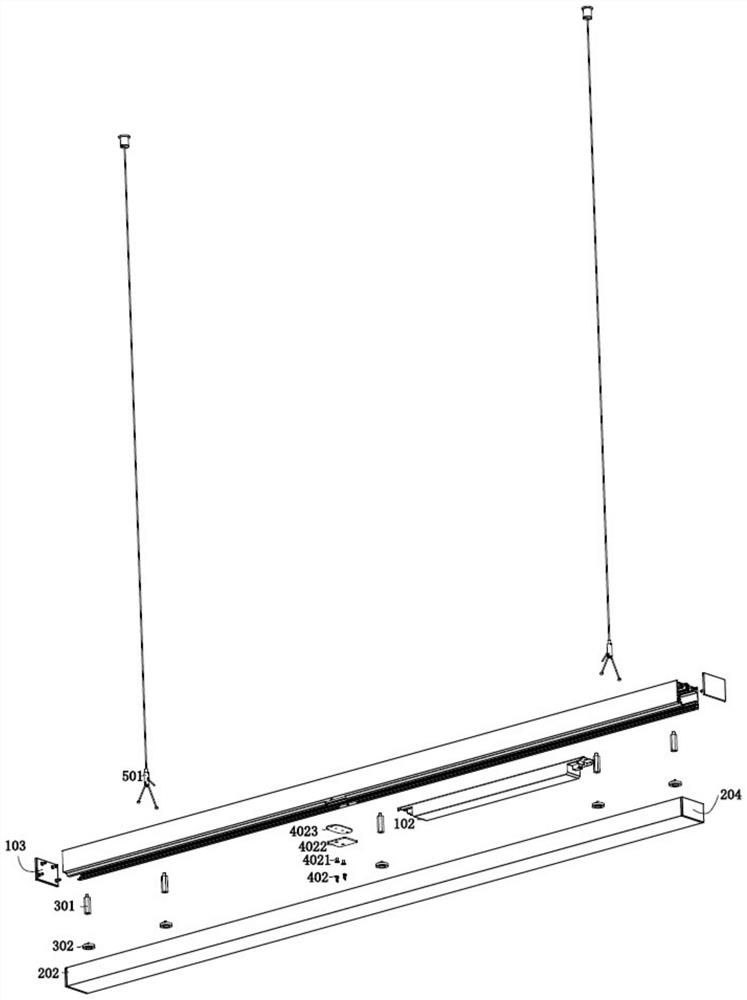

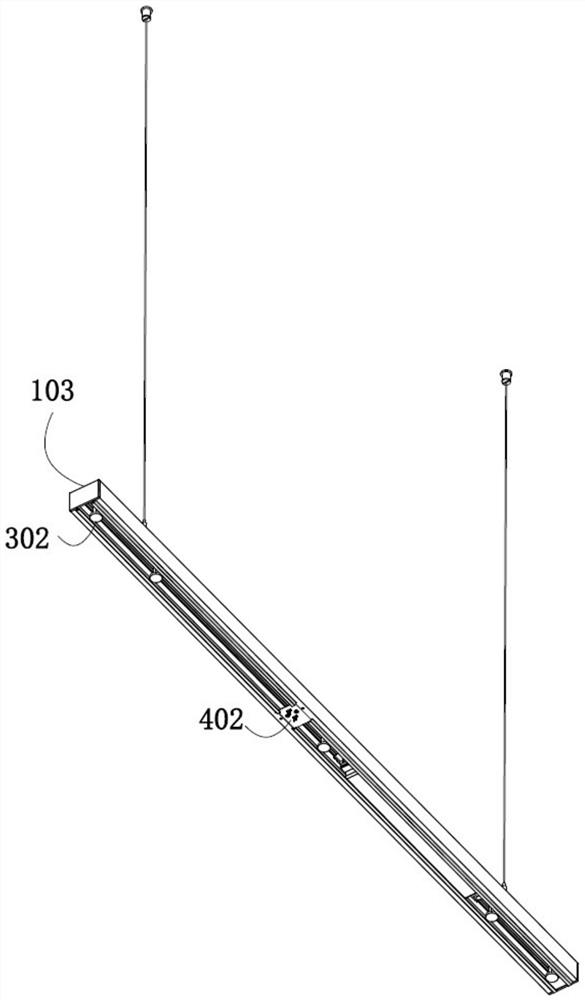

[0030] see Figure 1 to Figure 3 , figure 1 It shows an LED linear light proposed in the embodiment of the present application, the LED linear light includes a lamp holder 101, a driving module 102 and at least one light source module 201 installed on the lamp holder 101, the light source module 201 includes a lampshade 202 and the light source assembly 203 fixed in the cavity surrounded by the lampshade 202, the light source module 201 and the lamp holder 101 realize structural separation or fixed connection through the fixed connector 301, and the light source module 203 and the drive are realized through the electrical connector 401 The electrical connection between the modules 102, the fixed connector 301 and the electrical connector 401 include two parts respectively located on opposite sides of the light source module 201 and the lamp holder 101, and the light source module 201 and the lamp holder 101 are structurally fixed The electrical connection between the light so...

Embodiment 2

[0042] see Figure 9 Compared with the first embodiment, the difference between this embodiment and the first embodiment is that the lamp holder 121 is a T-shaped structural member with a groove 1211 formed in the middle, the drive module 122 is installed inside the groove 1211, and the two sides of the groove 1211 are formed for The side plates 1212 of at least two light source modules 221 are fixedly installed. The opening of the groove 1211. The lamp holder 121 of the T-shaped structure can fix two or more light source modules 221 on the lamp holder 121 to realize a double-lamp integrated or multi-lamp integrated, thus meeting different requirements. Of course, it is not limited to this method, and based on this method, it can be extended and improved to a form of fixing a plurality of light source modules 221 on the lamp holder 121 .

Embodiment 3

[0044] see Figure 10 Compared with the first embodiment, the difference between this embodiment and the first embodiment is that, in addition to the suspension assembly 531, the linear LED line light also includes a fixed lamp holder 631 fixed on the ceiling. The fixed lamp holder 631 is hollow inside and has a built-in drive module. 132, the drive module 132 is not built into the lamp holder 131. In a preferred embodiment, fixed lamp holder end caps 6311 are respectively provided at both ends of the fixed lamp holder 631, and the fixed lamp holder end caps 6311 fix and seal the two ends of the fixed lamp holder 631, and the grooves of the fixed lamp holder 631 The opening of the type structure is provided with a cover plate 6312 to seal the opening. The lamp holder 131 is fixedly connected to the light source module 231 and connected to the fixed lamp holder 631 fixed on the ceiling through the suspension assembly 531 . Therefore, the separate structure of the fixed lamp h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com