Condenser rubber ball cleaning device

A technology for cleaning devices and condensers, which is applied to cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc. It can solve the problems of heat exchange efficiency decline, condenser end difference increase, rubber ball escape, etc. problems, to achieve the effect of ensuring safe and economical operation, increasing circulating water flow, and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

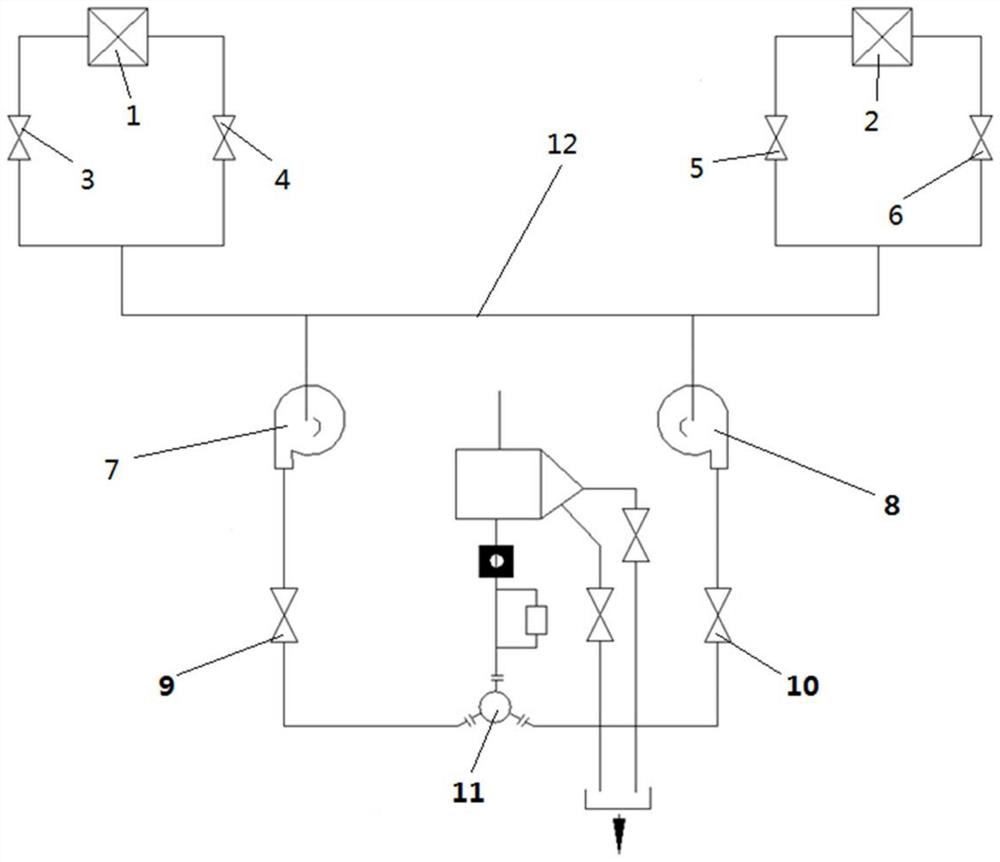

[0024] (1) Device structure and connection relationship:

[0025] Such as figure 1 The condenser rubber ball cleaning device shown is mainly composed of 2 ball collecting nets, 2 condenser ball cleaning pumps, 1 ball collector and 1 control cabinet. The ball collecting nets A and B are respectively placed in the condenser A and B circulating water outlet pipes. The ball collecting nets are opened when cleaning is not performed, and the ball collecting nets are closed when cleaning so that the rubber balls are in the condenser circulating water pipes. Clean cycle. The condenser small ball cleaning pump plays a role in promoting the circulation of small balls and collecting the balls. After the balls are recovered by the ball collecting net plate, the small balls are pumped out by the cleaning pump to the condenser circulating water inlet pipe. After cleaning the rubber balls of the condenser, close the ball collection net plate in the ball collector to collect the balls.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com