Vertical shielding motor heat exchanger fault processing device and use method

A technology for shielding a motor and a processing device, which is applied in the field of a fault treatment device for a vertical shielded motor heat exchanger, can solve the problem that the conventional heat exchange between the primary cooling water and the secondary cooling water cannot be realized, the temperature of the primary cooling water is increased, and the motor is damaged. problems, to achieve the effect of increased height, increased circulating water flow, and increased water storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

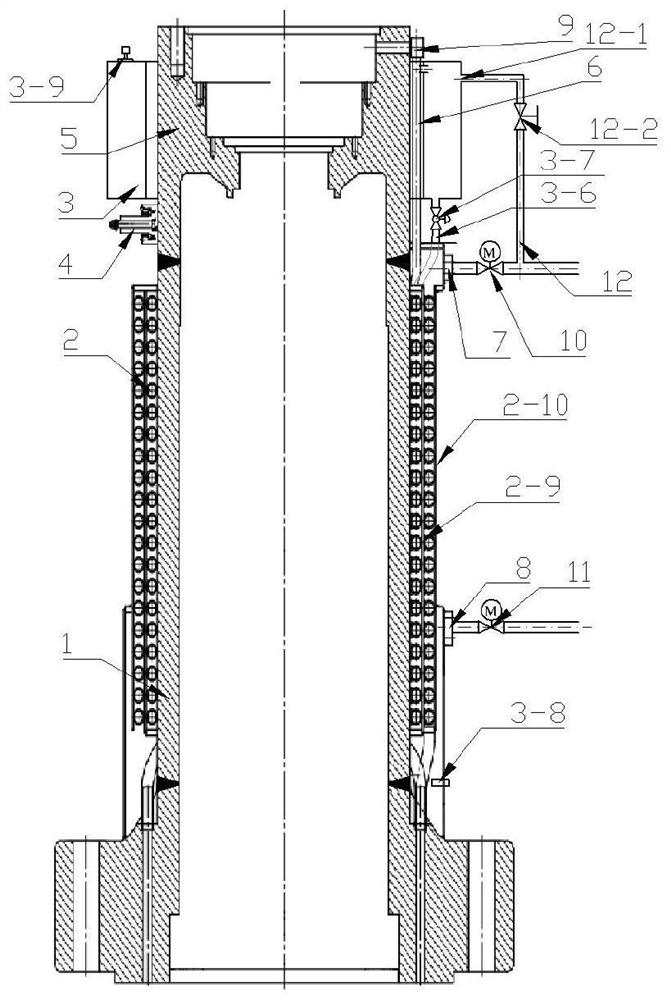

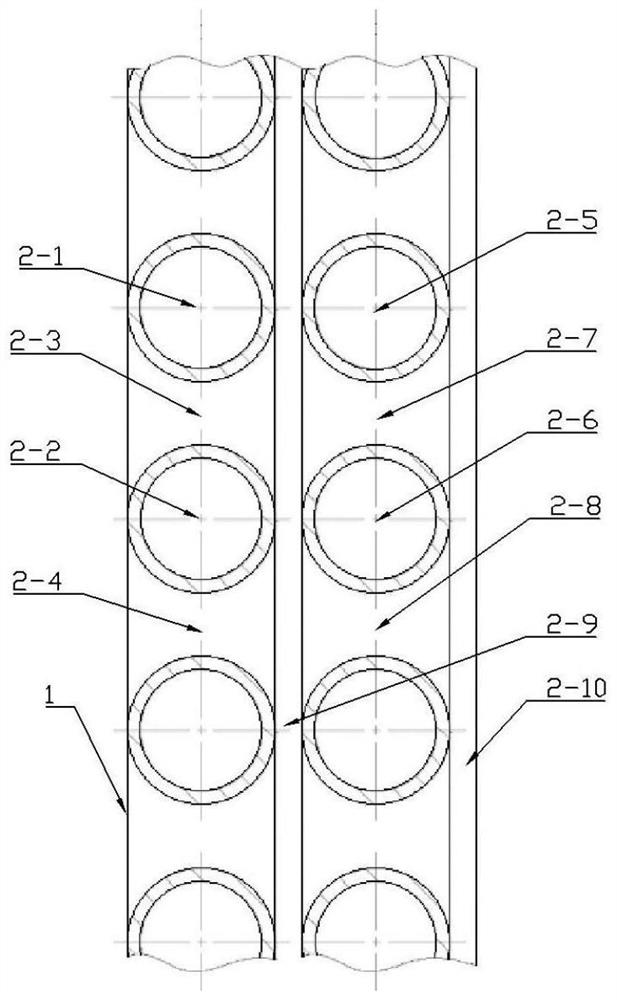

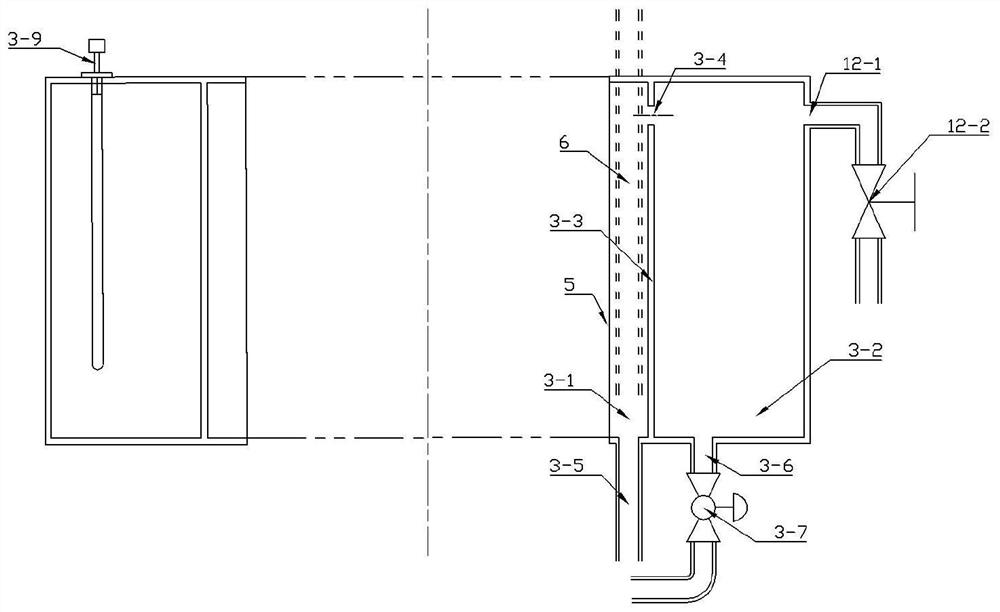

[0026] Example: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown in the figure, this specific embodiment adopts the following technical solutions: a fault treatment device for a vertical shielded motor heat exchanger and a method of use, which comprises a casing 1, a heat exchanger 2, a water storage container 3, a lead 4, a casing Forgings 5, motor primary cooling water inlet pipe 6, heat exchanger secondary cooling water inlet flange 7, heat exchanger secondary cooling water outlet flange 8, heat exchanger secondary cooling water inlet valve 10, heat exchanger 2 Secondary cooling water outlet valve 11 , bypass water supply device 12 . The heat exchanger 2 includes: the inner layer No. 1 spiral tube 2-1, the inner layer No. 2 spiral tube 2-2, the inner layer No. 1 spiral groove 2-3, the inner layer No. 2 spiral groove 2-4, and the outer layer No. 1 Spiral tube 2-5, outer layer No. 2 spiral tube 2-6, outer layer No. 1 spiral groove 2-7, oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com