Combined cooling system and method for combining cooling water of auxiliary machine into cooling tower between main machine

A technology for cooling water and cooling systems of auxiliary equipment, applied in indirect heat exchangers, fixed conduit components, lighting and heating equipment, etc., to achieve the effects of reducing equipment operating costs, unifying cooling equipment schemes, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

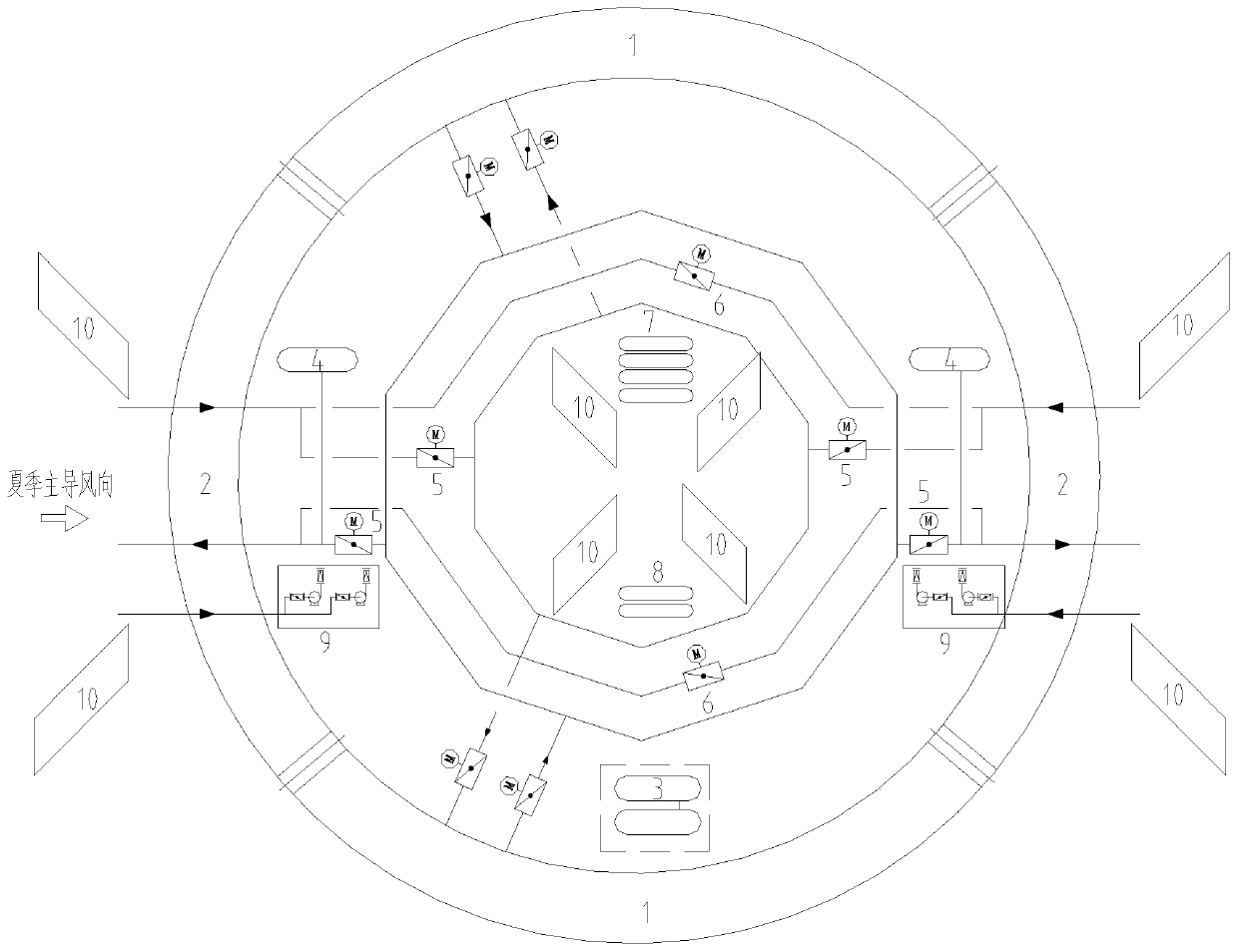

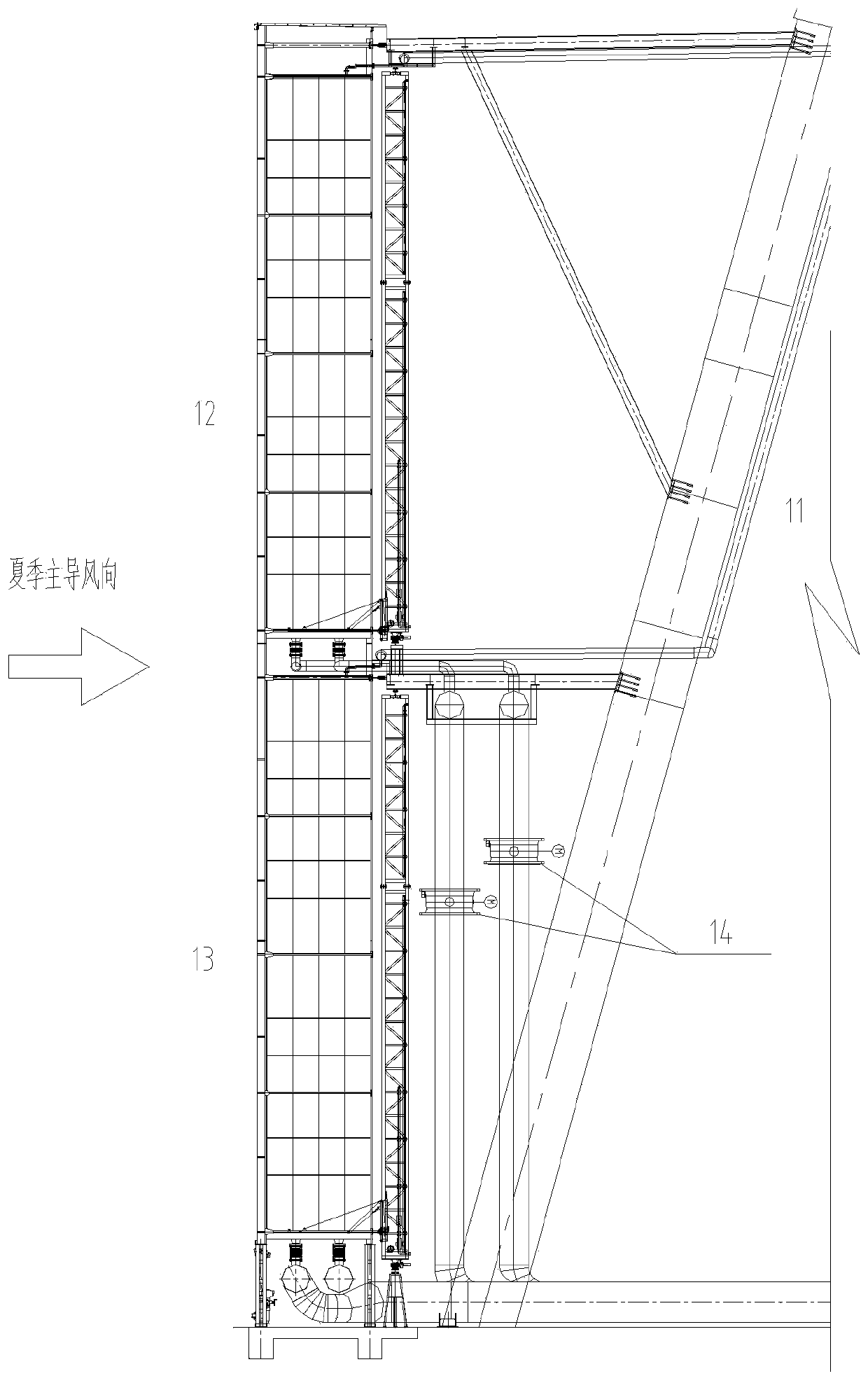

[0032]The combined cooling system of the auxiliary machine cooling water into the cooling tower of the main machine room refers to the combined cooling system in which the auxiliary machine cooling water system of the indirect air-cooled unit is merged into the cooling tower of the main machine room. This system organically combines two independent systems of main machine cooling and auxiliary machine cooling, and cancels the auxiliary machine cooling system that must be set separately for conventional units, thereby saving the structures and equipment required for the auxiliary machine cooling system and saving project investment. , saves the factory land, and reduces the operating costs of fans and other equipment in the auxiliary system that is set separately. It has the advantages of unified cooling equipment scheme, centralized arrangement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com