A kind of MEMS inertial device sensitive structure frequency testing device and method

A technology of sensitive structures and inertial devices, applied in measurement devices, instruments, etc., can solve problems such as time lag and waste of resources, and achieve the effect of improving efficiency, shortening production cycles, and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and embodiments.

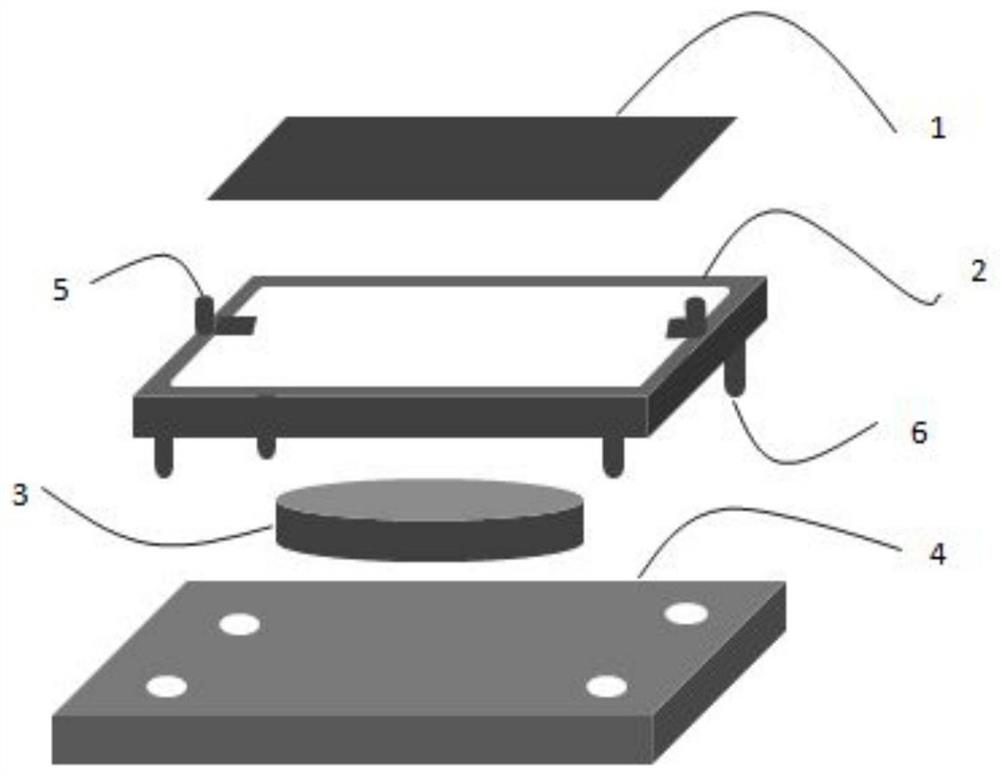

[0019] figure 1 It is the design principle diagram of the frequency testing device of the sensitive structure of the present invention. The testing device includes an electric XY axis moving stage 4 and a piezoelectric ceramic frequency sweeping device. Metal pressing piece 5, positioning nut 6. The piezoelectric ceramic 3 is rigidly connected with the wafer-bearing table 2 , and the piezoelectric ceramic 3 is bonded under the wafer-bearing table 2 by using paraffin wax. The wafer substrate 1 is pressed and fixed on the wafer support table 2 by a rigid metal pressing piece 5 . The wafer stage 2 is fixed on the electric XY-axis moving stage 4 through the positioning nut 6 .

[0020] The selection of the electric XY axis moving stage 4 mainly considers that the moving range matches the size of the wafer substrate 1 .

[0021] The selection of the piezoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com