A kind of testing method of colloidal particle microfluidic shear force

A technology of colloidal particles and shear force, which is applied in the direction of applying stable shear force to test the strength of materials, measuring devices, instruments, etc., to achieve reliable and high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A fluid flow rate calibration method for loading the microfluidic shear force of colloidal particles in a fluid environment, the specific steps are as follows:

[0035] 1. Insert the prepared colloidal particle suspension into Channel 1 in the flow cell and the background fluid into Channel 2. Among them, the colloidal particles are polystyrene microspheres with a diameter of 4.38 μm, and the background fluid is ultrapure water. Instrument model: Lumicks super-resolution single molecule dynamic analyzer - C-Trap.

[0036] 2. Capture colloidal microspheres with optical tweezers and keep them stationary.

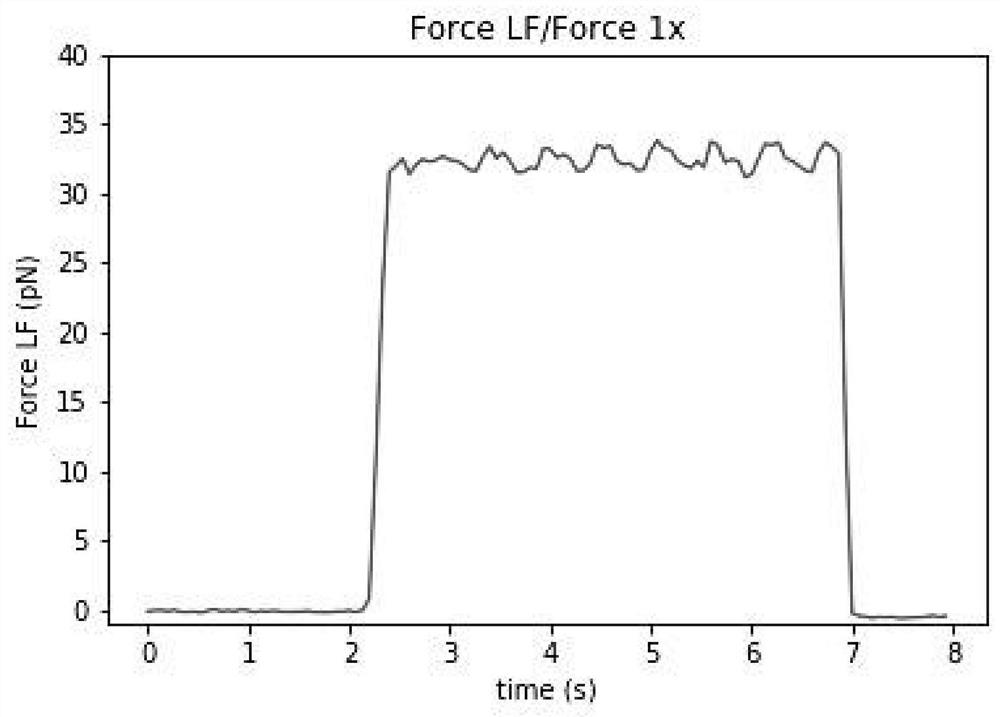

[0037]3. Flow rate calibration. (1) Set the power of the electrostatic displacement table to 100%, and obtain a graph of the relationship between the shear force and time of the colloidal particles under the maximum power and maximum translational speed ( Figure 1 ); (2) When the relationship between the shear force and the time of the colloidal particles is stable in the g...

Embodiment 2

[0040] A test method for microfluidic shear force of colloidal particles in ultrapure water environment, the specific steps are as follows:

[0041] 1. The prepared colloidal particle suspension is fed into Channel 1 in the flow cell, and the background fluid that needs to be detected is fed into Channel 2. Among them, the colloidal particles are polystyrene microspheres with a diameter of 4.38 μm, and the background fluid is ultrapure water. Instrument model: Lumicks super-resolution single molecule dynamic analyzer - C-Trap.

[0042] 2. Capture colloidal microspheres with optical tweezers and keep them stationary.

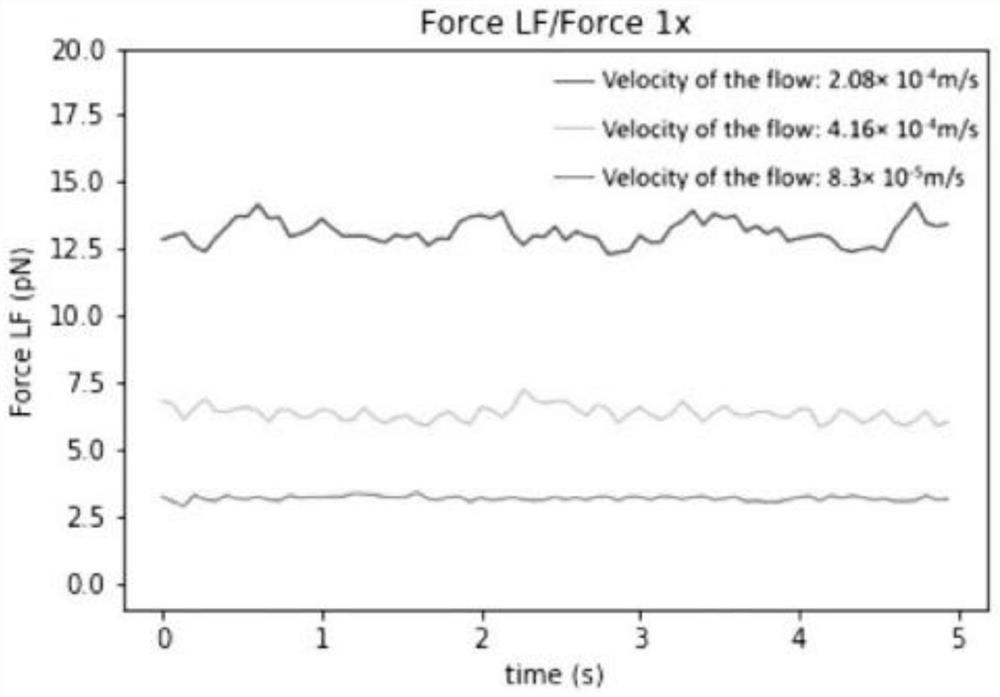

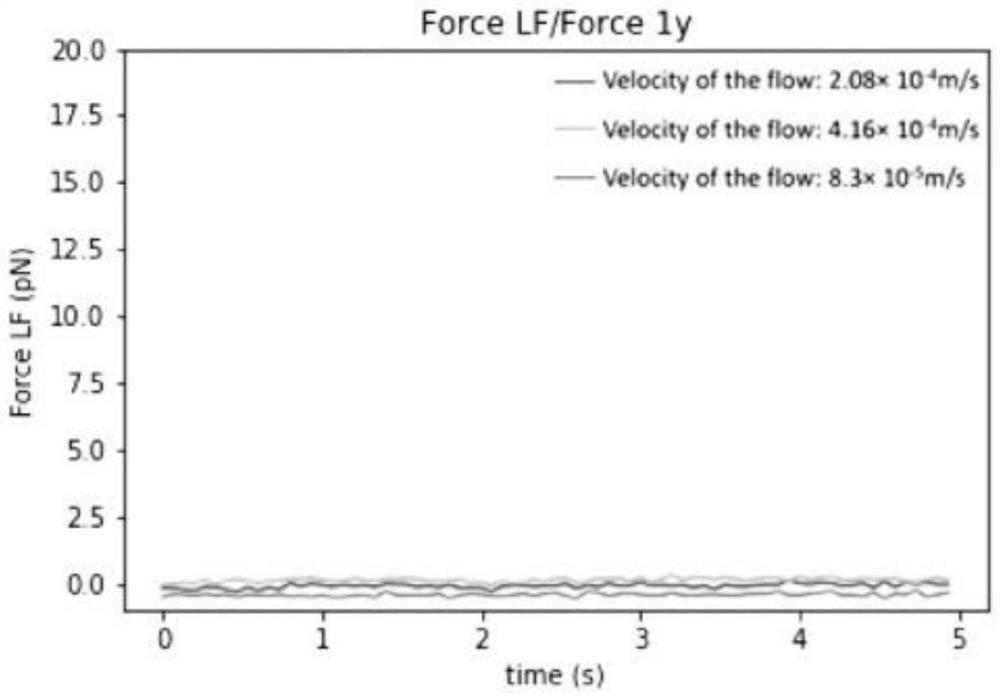

[0043] 3. Flow rate calibration. (1) Set the power of the electrodynamic displacement table to 100%, and obtain a graph of the relationship between shear force and time of colloidal particles under maximum power and maximum translational speed; (2) When the relationship between the shear force and the time of the colloidal particles is stable in the graph, the fluid ...

Embodiment 3

[0048] A test method for microfluidic shear force of colloidal particles in a saline solution environment, the specific steps are as follows:

[0049] 1. The prepared colloidal particle suspension is fed into channel 1 in the flow cell, and the background fluid that needs to be detected is fed into channel 3. Among them, the colloidal particles are polystyrene microspheres with a diameter of 4.38 μm, and the background fluid is 100 mM KCl solution. Instrument model: Lumicks super-resolution single molecule dynamic analyzer - C-Trap.

[0050] 2. Capture colloidal microspheres with optical tweezers and keep them stationary.

[0051] 3. Flow rate calibration. (1) Set the power of the electrodynamic displacement table to 100%, and obtain a graph of the relationship between shear force and time of colloidal particles under maximum power and maximum translational speed; (2) When the relationship between the shear force and the time of the colloidal particles is stable in the graph, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com