Double-resource die job shop scheduling optimization method based on AMAS-GA nested algorithm

A technology for job workshops and optimization methods, applied in control/regulation systems, instruments, and comprehensive factory control, etc., can solve problems such as stagnation and long calculation time, and achieve the effects of reducing energy consumption and improving workshop production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

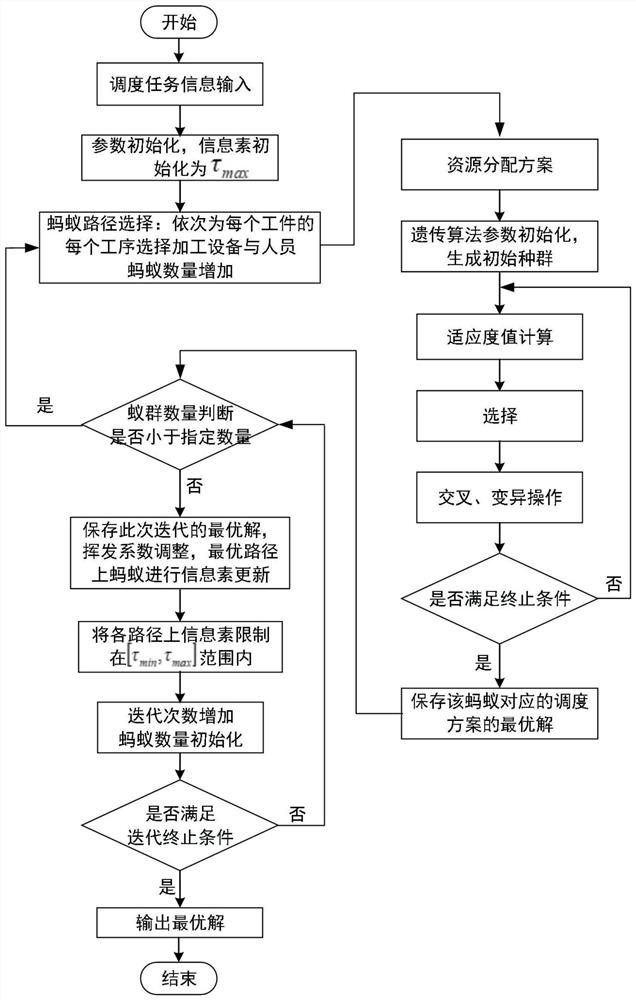

Method used

Image

Examples

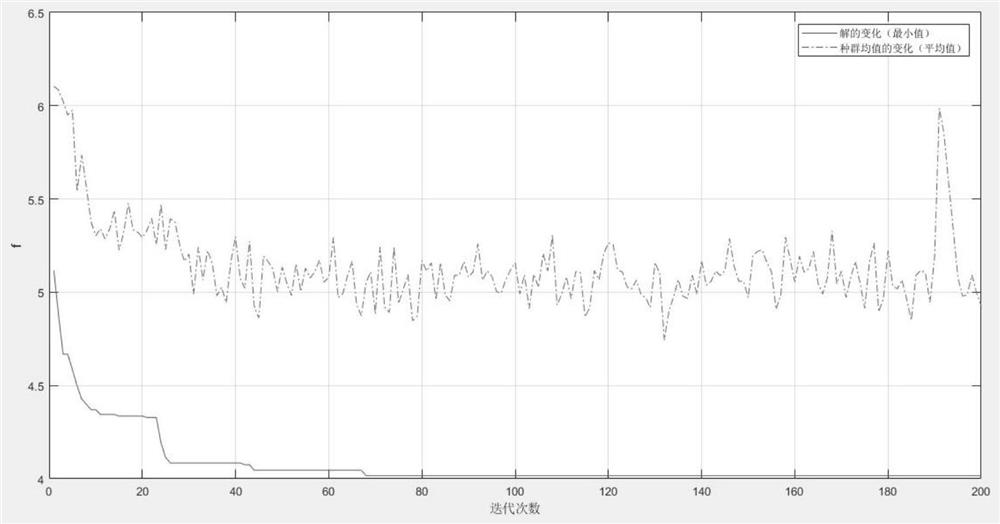

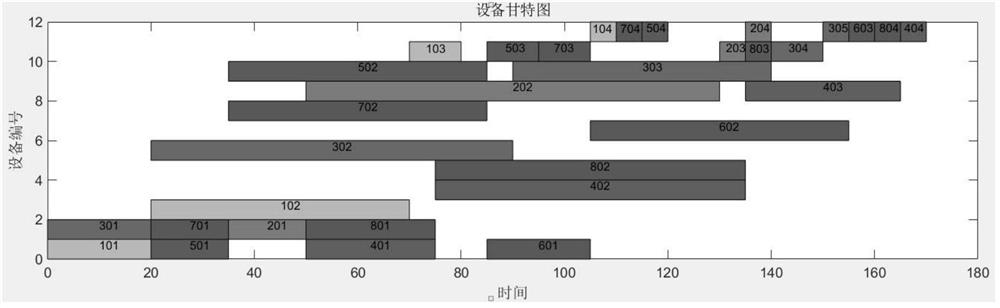

Embodiment 1

[0151] Taking a mold manufacturing company as the background, there are 12 mold processing equipment and 8 equipment operators in the workshop. There are 8 production tasks in a certain scheduling cycle. Each production task includes several processing procedures. Each processing procedure can be processed in at least one Candidate equipment resources are completed, and each equipment has at least one candidate operator. First, group equipment according to equipment function types, and determine the optional operators for each equipment group, as shown in Table 2; select the corresponding available equipment for each process according to the requirements of the process type and the equipment function model, and form the operator of each process The list of available equipment is shown in Table 3; the processing time of each process is shown in Table 4 (time unit: min). The power table of each equipment is shown in Table 5 (power unit: kW).

[0152] Table 2 List of optional op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com