Stator with a cooling jacket, electric machine and motor vehicle

A technology for cooling jackets and motor vehicles, which is applied in the direction of electric components, cooling/ventilation devices, electromechanical devices, etc., and can solve problems such as motor failure and motor overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

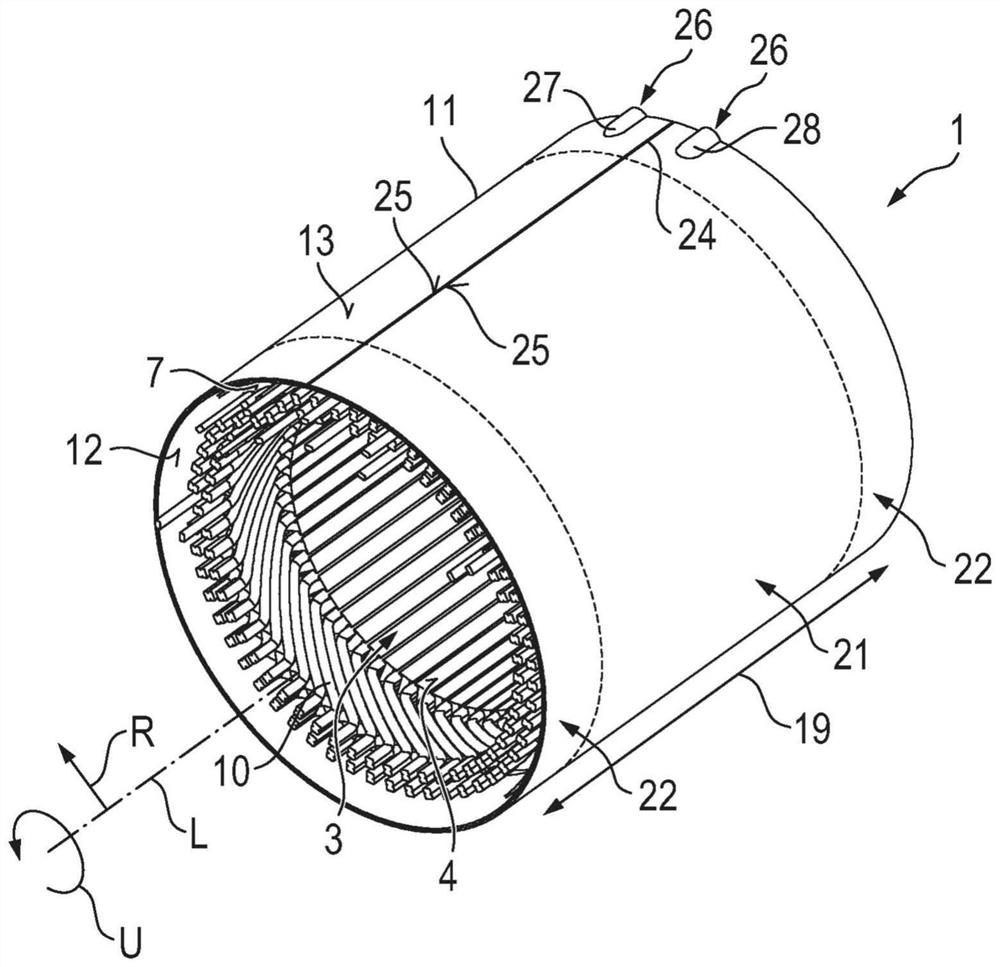

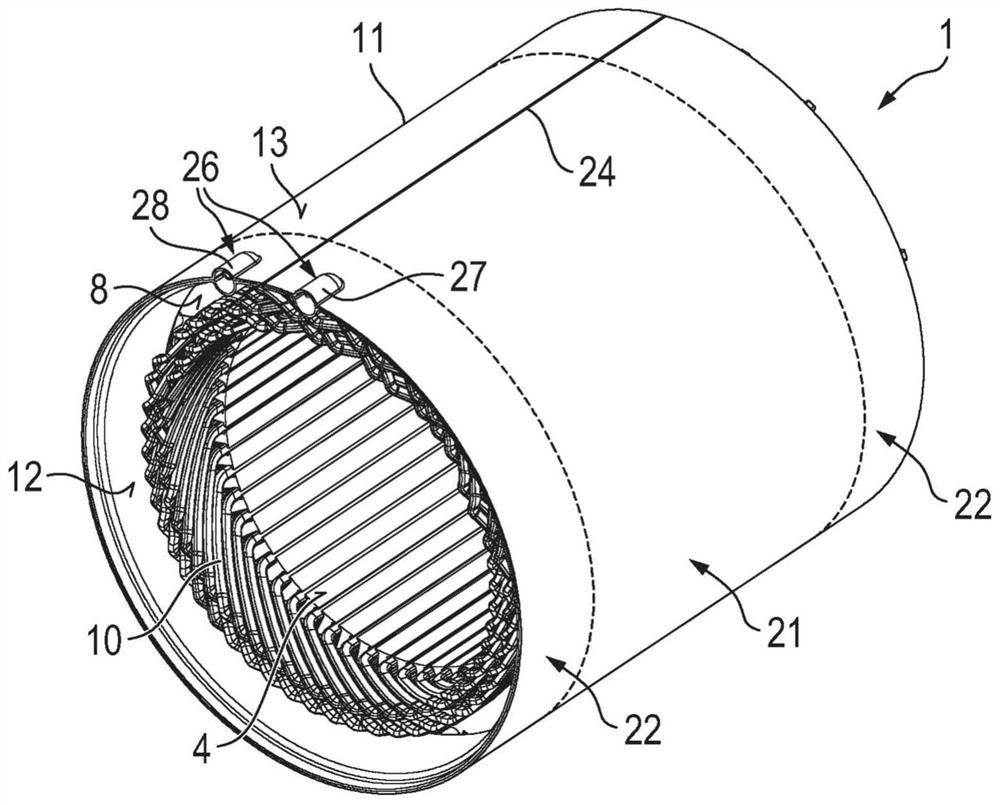

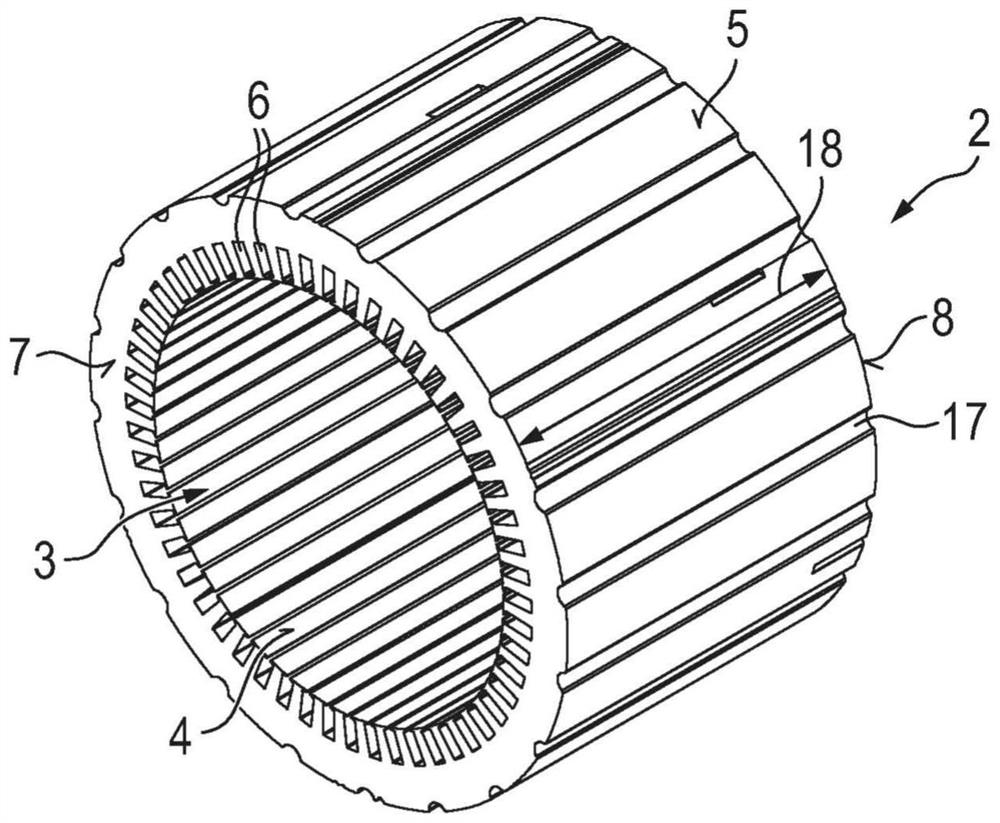

[0041] figure 1 and figure 2 A first embodiment of a stator 1 for an electric machine of an electrically driveable motor vehicle, not shown here, is shown from a different perspective. The stator 1 has a lamination stack 2 which is in image 3 shown as a separate illustration. The laminated core 2 is formed circumferentially around the longitudinal axis L of the stator 1 in the circumferential direction U and is hollow-cylindrical. The longitudinal axis L also corresponds to the axis of rotation about which the rotor, not shown here, which is mounted in the cylindrical cavity 3 of the laminated core 2 , rotates. The laminated core 2 has an inner side 4 surrounding the cylindrical cavity 3 . Furthermore, the laminated core 2 has an outer side 5 opposite the inner side 4 in the radial direction R. A plurality of winding slots 6 are formed distributed in the circumferential direction U in the inner side 4 of the laminated core 2 . The winding slots 6 extend axially along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com