Wire electrical discharge machining device

An electrical discharge machining and wire technology, applied in the field of wire electrical discharge machining devices, can solve the problems of wire electrode WE tension fluctuation, hindering wire discharge accuracy and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

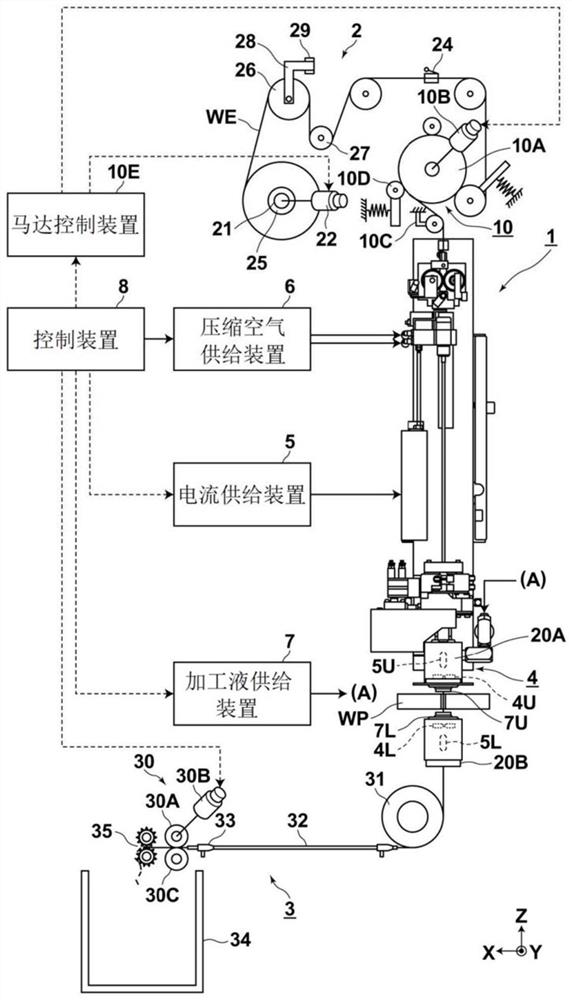

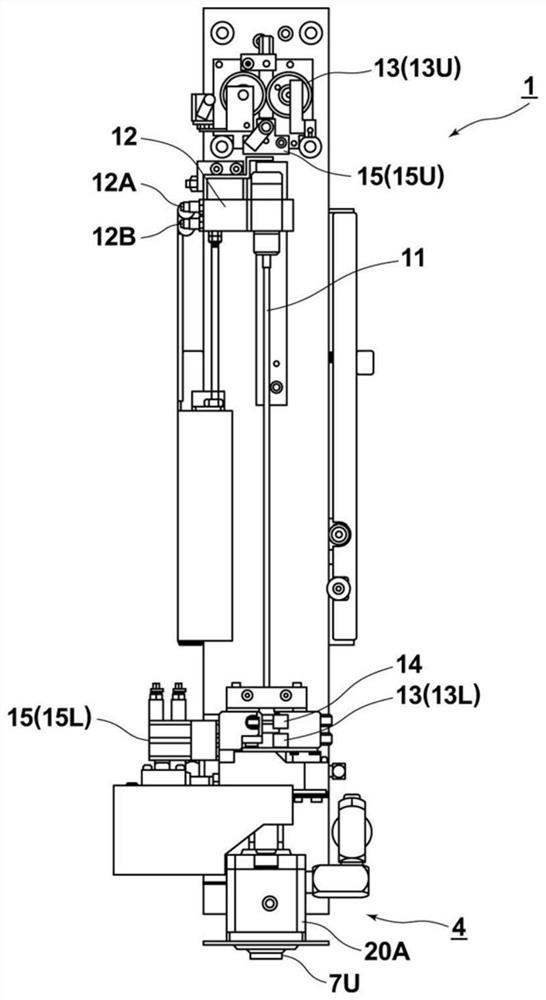

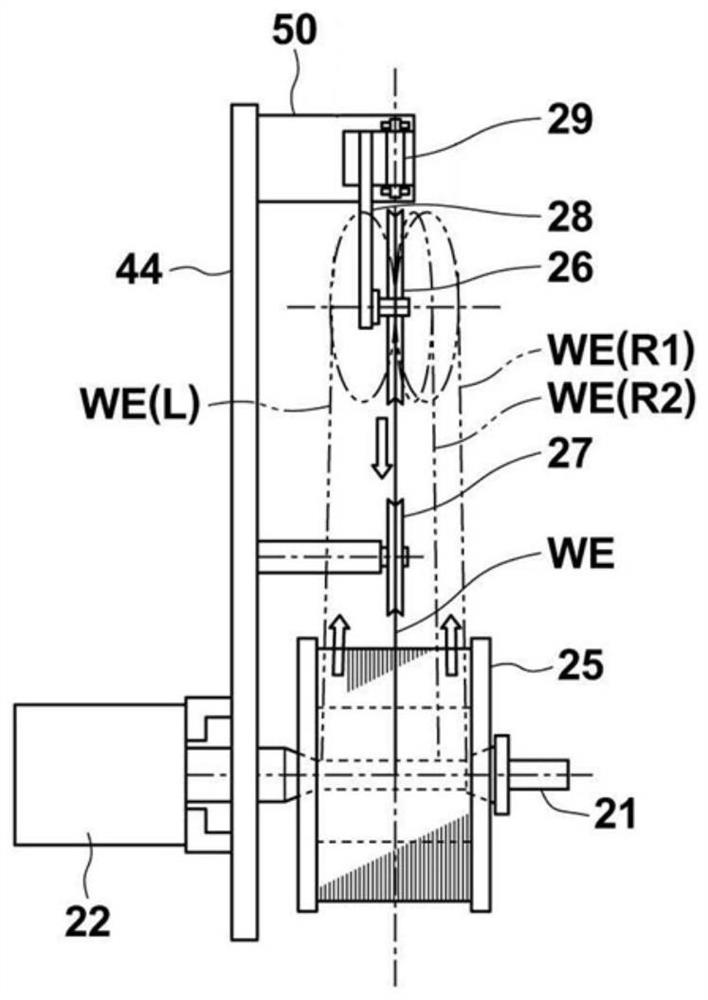

[0061] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a figure which shows the 1st Embodiment of the electric wire electric discharge machining apparatus of this invention. exist figure 1 In , a wire electric discharge machining device is schematically shown so as to make the predetermined travel path of the wire electrode clear. exist figure 1 In the figure, the automatic splicing device, wire supply mechanism, and wire guide mechanism are shown as viewed from the front of the machine, and the wire collection mechanism is shown as viewed from the side of the machine. Below, refer to figure 1 and figure 2 , and the configuration of the electric wire electric discharge machining device according to this embodiment will be described.

[0062] The wire electrode WE and the workpiece WP are arranged to face each other so that a predetermined machining gap is formed between the wire electrode WE and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com