A kind of preparation method of hollow raw bamboo equal-diameter bamboo cylinder

A technology of hollow raw bamboo and bamboo tube, which is applied in the direction of manufacturing tools, mechanical equipment, sugarcane machining, etc., can solve the problems of difficult large-scale production of bamboo, difficult processing, and easy cracking, etc., to improve the utilization rate of bamboo tubes, the method is simple, Ease of scale-up production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

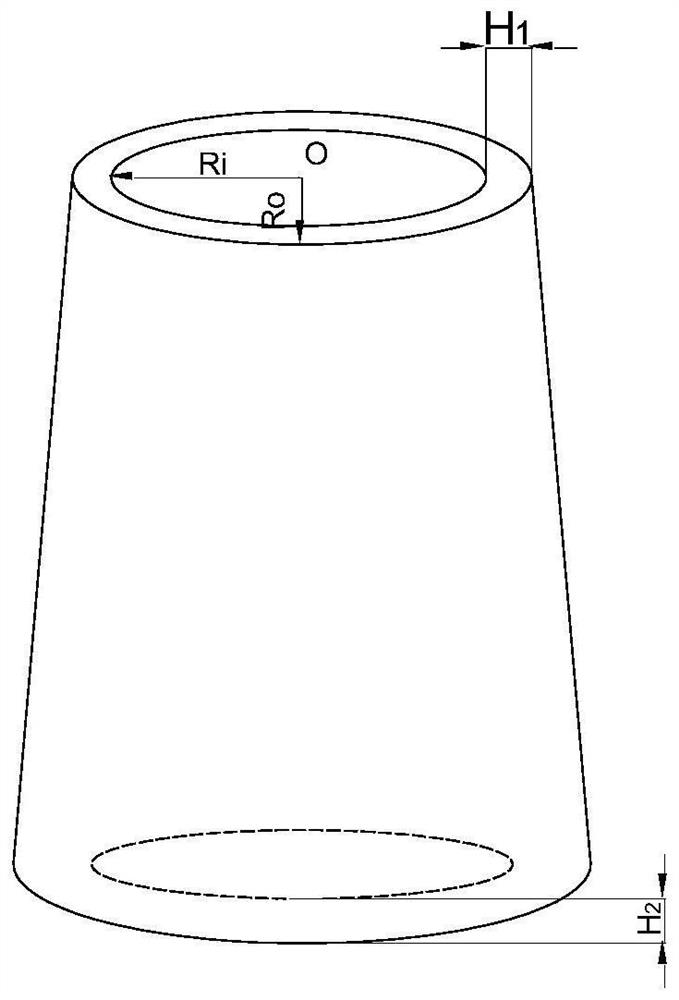

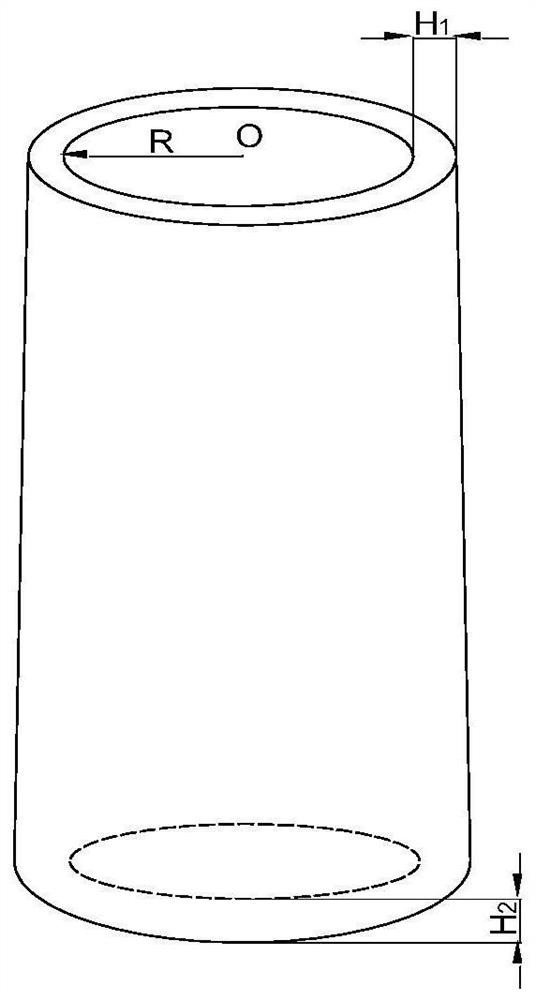

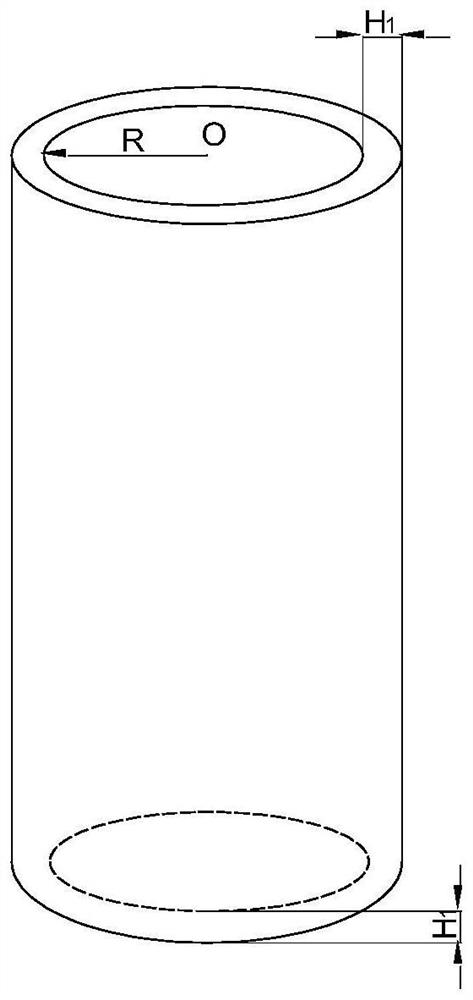

[0032] (1) Select fresh moso bamboo without mildew and rot defects, with a diameter between 100 and 160 mm, and saw and cut it into bamboo tubes according to the length of use; then, the outer nodes, inner nodes and bamboo partitions of the bamboo tubes are respectively removed from the outer nodes and the inner parts. Remove it on the knot machine, so that the outer joint of the bamboo tube has no protrusion, and the inside is hollow. After sawing, the wall thickness of the small end of the bamboo tube is H 1 , the bulkhead wall thickness is H 2 .

[0033] (2) cutting the bamboo tube. Cut off a part along the longitudinal direction of the bamboo tube, according to the arc length formula or Calculate the size of the central angle corresponding to the arc that needs to be cut out, wherein, the size of the central angle corresponding to the cutout arc, the inner diameter circle is slightly larger than the outer diameter circle, so that the length of the arc length of the sm...

Embodiment 2

[0040] (1) Select fresh moso bamboo without mildew and rot defects, with a diameter between 100 and 160mm, and saw and cut it into bamboo tubes according to the length of use; then, the outer nodes, inner nodes and bamboo partitions of the bamboo tubes are respectively removed from the outer nodes and the inner parts. Remove it on the knot machine, so that the outer joint of the bamboo tube has no protrusion, and the inside is hollow. After sawing, the wall thickness of the small end of the bamboo tube is H 1 , the bulkhead wall thickness is H 2 .

[0041] (2) cutting the bamboo tube. Cut off a part along the longitudinal direction of the bamboo tube, according to the arc length formula or Calculate the size of the central angle corresponding to the arc that needs to be cut out, wherein, the size of the central angle corresponding to the cut out arc, the inner diameter circle is slightly larger than the outer diameter circle, so that the arc lengths of the small head of t...

Embodiment 3

[0048] (1) Select fresh moso bamboo without mildew and rot defects, with a diameter between 100 and 160mm, and saw and cut it into bamboo tubes according to the length of use; then, the outer nodes, inner nodes and bamboo partitions of the bamboo tubes are respectively removed from the outer nodes and the inner parts. Remove it on the knot machine, so that the outer joint of the bamboo tube has no protrusion, and the inside is hollow. After sawing, the wall thickness of the small end of the bamboo tube is H 1 , the bulkhead wall thickness is H 2 .

[0049] (2) cutting the bamboo tube. Cut off a part along the longitudinal direction of the bamboo tube, according to the arc length formula or Calculate the size of the central angle corresponding to the arc that needs to be cut out, wherein, the size of the central angle corresponding to the cut out arc, the inner diameter circle is slightly larger than the outer diameter circle, so that the arc lengths of the small head of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com