Packing device for betel nut production

A betel nut and box body technology, which is applied in the field of packaging devices for betel nut production, can solve the problems of complex process, increase process flow, waste time and the like, and achieve the effects of improving production efficiency and simplifying packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

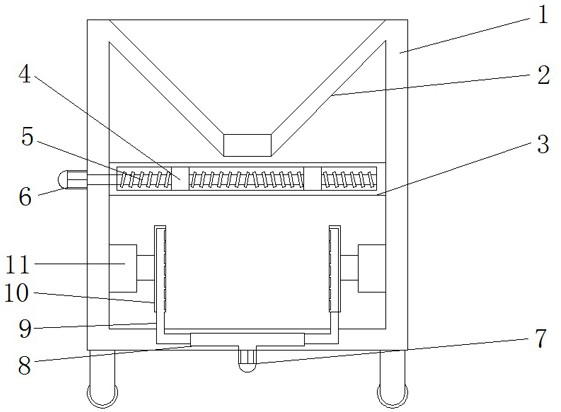

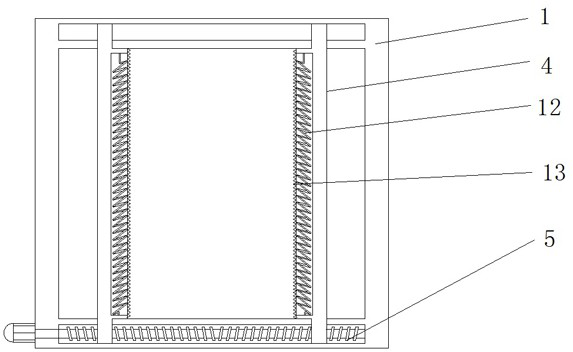

[0018] Embodiment 1, with reference to Figure 1-2 , a packing device for betel nut production, comprising a box body 1, a tapered groove is opened on the top of the box body 1, and a funnel 2 is installed on the inner wall of the tapered groove, and a support rod 3 is welded on the inner wall of both sides of the box body 1, and the support rod 3 There is a chute on the opposite side, the inner wall of the chute is slidably connected with a slider 4, and one end of the slider 4 is provided with a threaded hole, the inner wall of the threaded hole is screwed with a two-way threaded rod 5, and one end of the two-way threaded rod 5 is connected with a motor 6 A vacuum pump 7 is installed at the center of the outer wall of the bottom of the box body 1, and the suction end of the vacuum pump 7 is connected with a telescopic rod 8, and one end of the telescopic rod 8 is connected with an air outlet pipe 9, and one end of the air outlet pipe 9 is connected with a rubber plate 10, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com