Packaging box molding machine applied to full-automatic packaging line for LED lamp tube

A fully automatic packaging and LED light tube technology, which is applied to the types of packaged items, packaging, and transportation packaging, can solve problems such as time-consuming, inaccurate light tubes, and easy damage to packaging boxes, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

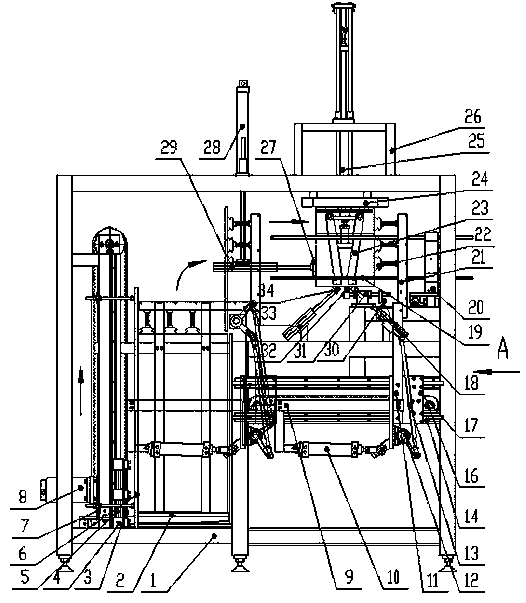

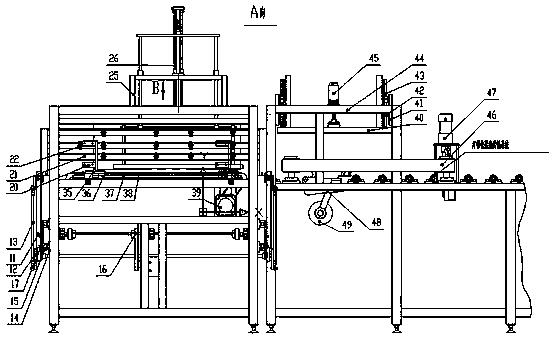

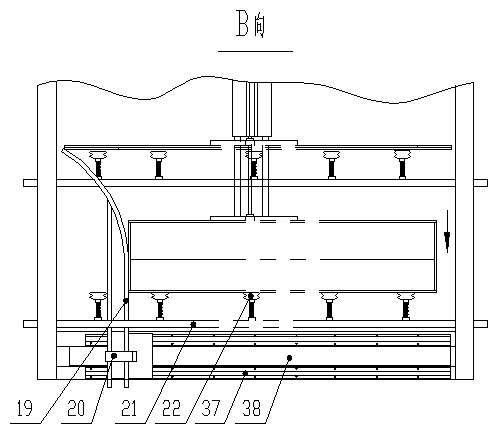

[0014] Full-automatic packaging line for LED lamps, box forming machine, the frame (1) is equipped with a feed bin floor frame (2), and a track A (4) is set beside the feed bin bottom frame (2), and track A is installed on the frame (1). (4) The track bearing A (3) is set on the top, the track bar (5) is set on the upper end of the track A (4), and the side plate (6) is set beside the track bar (5). A servo control motor (8) is arranged on the side, and the servo control motor (8) is fixed on the servo control motor fixing frame (7), and a vacuum suction cup rotation control cylinder fixing frame (9) is arranged on the frame. A vacuum suction cup rotation control cylinder (10) is arranged at the lower end of the suction cup rotation control cylinder fixing frame (9), and a connecting plate (11) is arranged beside the vacuum suction cup rotation control cylinder fixing frame (9), and a vacuum suction cup rotation control cylinder (10) A vacuum suction cup rotating device (12) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com